Please help! Prusament filament lifting off of print bed

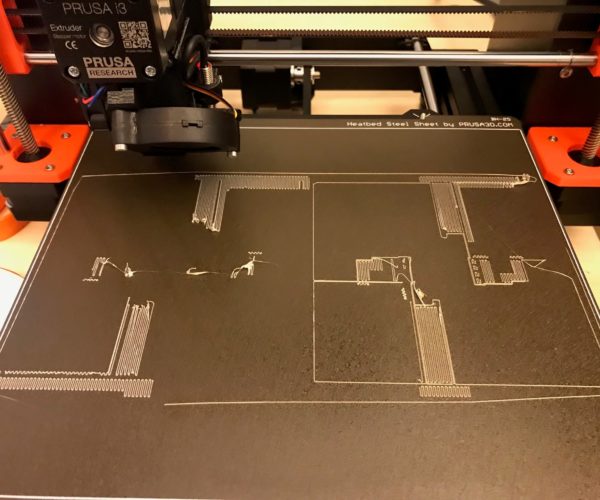

I am a beginner in 3d printing but chose the technique for a project with a tight deadline mistakenly. I have been previously printing with the packaged silver PLA from Prusa but changed to Vanilla Prusament for my work task. For some reason I cannot get the first layer to stick: the printed lines lift off the print bed as the extruder moves around causing blobs that eventually result in a crash. I am running the stock nozzle but have also tried printing with a Microswiss plated nozzle as well as a Microswiss hardened tool steel nozzle with no success. I switched back to the stock nozzle thinking that my problems might be caused by the Prusaslicer Prusament heat/retraction settings being wrong when printing with the other nozzles but that does not seem to be the case. I have also tried cleaning the build plate thorougly and looked at a large quantity of first layer trouble shooting guides to no avail.

I believe that my Z first layer calibration is correct as the calibration test works fine with the filament adhering to the bed nicely. However, having gone between different heat values and retraction length values for 2 days now, I cannot think of a solution. The print does not even get off the first layer without crashing. Please help.

RE: Please help! Prusament filament lifting off of print bed

I'm going to paste the standard approach for dealing with adhesion issues in the hope that's all you're dealing with. This is a common problem that can be caused or aggravated by two factors that need to work together well for successful prints. Here's mama's tried and true copypasta recipe to get you going...

-

A dirty PEI print surface. Even if you don't think this is the cause, it's always a good idea to make sure your PEI surface is clean before trying any other fixes. If it's a smooth PEI sheet, take it to the kitchen sink and give it a good dunk with Dawn (original formula, no vinegar or hand softener variants) dishwashing soap or your local equivalent (e.g. Fairy in UK). Use a clean paper towel to clean it off, and another to dry it. Avoid using any sponge or cloth that has been in contact with grease. Above all else, avoid touching the PEI print surface. Once it's good and clean, you should be able to use 91%+ isopropyl alcohol between prints, 100% acetone when that fails , and another dunk when acetone fails. Worst-case, use a 3M 7445 ScotchBrite pad or equivalent on smooth PEI to give it a very light buff, but only infrequently. If you've got a textured powder-coated PEI print surface, the official instructions are to use 91%+ isopropyl alcohol on it only.Many have had good luck getting started with these sheets by giving them a wipe with 100% acetone and a dunk with Dawn. Some have even resorted to scuffing them up with a fine abrasive pad (see above). Either way, there's no real warranty on these sheets. YMMV.

-

If you have not already done so, try using Jeff Jordan's "Life Adjust" procedure for calibrating your Live-Z setting. It is much easier to use and understand than the on-board routine. It's much easier to make mid-print adjustments accurately with. In general, start high (less negative) and work lower (more negative) in large increments (e.g. 0.1mm) until the filament starts to stick on its own. When you've got your Live-Z setting adjusted properly, you should be able to gently rub the extruded lines on the PEI surface without dislodging them. Then start lowering (more negative) the level until there are no gaps between layers.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Please help! Prusament filament lifting off of print bed

To add to Bobstro's excellent advice, which is the first step in adhesion problems, it looks from the picture like those are the first layer of supports being laid down....

Recently, I have had issues with globbing on the first layer of supports where it does what you are showing in the pic. I am unsure what has caused this to happen, but have had good luck with slowing down the first layer or two to 75 % to ensure the supports are laid down nice and flat. Then after there is a good base layer of supports, I return the speed to 100% and let the print go. It is not optimal and the final resolution, but works from what I can tell, so it is something to try after ensuring the build plate is nice and clean if you are still getting the problem.

Observation: I noticed it seems like recently (since the last update) the speed of supports seems faster on my machine/PrusaSlicer... I am unsure if I did something or if it was one of the updates that did it. I suspect that the updates to slicer/firmware also include changes made to the settings for speed in support materials - I do not have this problem with nonsupport prints - and it is kind of maddening. I have to go back and find some older GCODEs where this did not happen and compare the settings to see if i can find what is causing it.

EDIT: I see that the border lines are broken at the bottom and right side in your picture, that is most likely cleanliness like Bobsto said, but the support suggestion is helpful too.

Strange women, laying in ponds, distributing swords, is hardly a basis for a system of governance!

RE: Please help! Prusament filament lifting off of print bed

A textured sheet is well known for not being PLA friendly. And alcohol is well known as being inadequate for cleaning fingerprints off print sheets. Soap and water is a best next step. But be sure to print immediately after the soap and water wash or at least bake the sheet dry for 30 minutes to get all the moisture out of the PEI sputter.

RE: Please help! Prusament filament lifting off of print bed

I agree with the suggestions above as being primary causes but from the picture I noticed even the skirt does not appear to be sticking. I see no signs of dragging from the extruder with a too low live z adjustment which will also lift ends or corners of long straight lines. If cleaning does not help slowly lower the live z adjustment easier to do on a print with a surface on the bed than with supports. If it starts globbing or dragging then raise it up until it stops that behavior.

I have found on my printer PLA will stick better at a bed temperature of 65. If you set bed temperature too high and have a large heavy model it may start to sink or melt with enough weight. I only need to raise bed temperature with long straight lines or short straight narrow lines. if the model has more curves it tends to not pull away in the corners. Radius your parts is your friend. You might try printing this with a raft also it doesn't appear to have much surface area on the plate.

RE: Please help! Prusament filament lifting off of print bed

One more suggestion. When I made 48 copies of a chain there were small rectangle parts approx 1.5 mm wide that would keep lifting off the print bed. I printed 4 at a time no problem. but with 48 copies if one failed the print was ruined. I ended up slowing the speed to 65 percent for the first 3 layers then going back up to 85 percent because it was a 28 hour print. I have been able too successfully print this a couple of times now.

RE: Please help! Prusament filament lifting off of print bed

Thanks for all your advice! Had to switch to another printer due to the work deadline but managed to fix the problem afterwards. The issue ended up being the build plate. I simply washed it thoroughly with warm water and dishwashing liquid, baked it on the printer for about 30 minutes, and it worked perfectly again.

RE: Please help! Prusament filament lifting off of print bed

Give it the detergent and water treatment as needed.

I do mine about monthly, to get off assorted residue.

RE: Please help! Prusament filament lifting off of print bed

Hello,

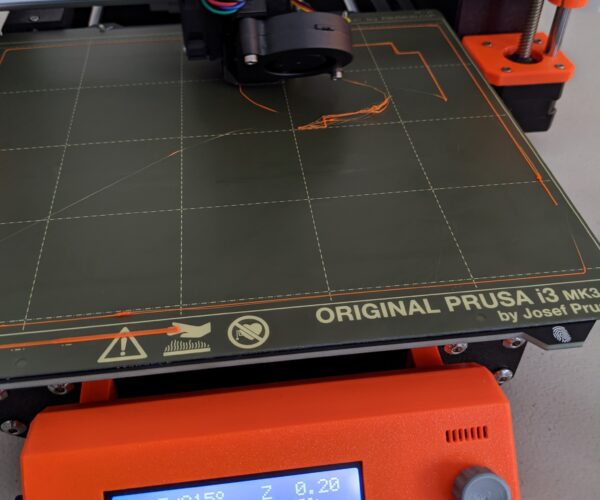

I started having similar issues today and came across this post. I took all of the advice here (except for live-z updating as I have my live-z fairly dialed in for other PLA that I have printed with) and I am still having issues.. curious if anyone would have any input.

This is my first day running with new Prusament spool that I purchased.. I'm a little concerned as I purchased 5 spools (this is only the first one I have opened). It seems to be missing sections and then later spitting all of the globbed filament out. You can particularly see that in the bottom right area of the print bed.

- MK3s printer

- Spool Information

- Print (Bed level test)

My printer has been working fantastic with the grey Prusa PLA sent with my new printer.. however, now that I have started using this Prusament PLA, I'm a little concerned. I was under the impression that this was supposed to be the best of the best filament I could use in my Prusa printer. I have also used a generic silk white PLA that I bought from Amazon that has been printing awesome as well. Is Prusament the problem?

Any help or suggestions would be appreciated - thank you so much!

--

Newb Printer

AKA - Stephen

RE: Please help! Prusament filament lifting off of print bed

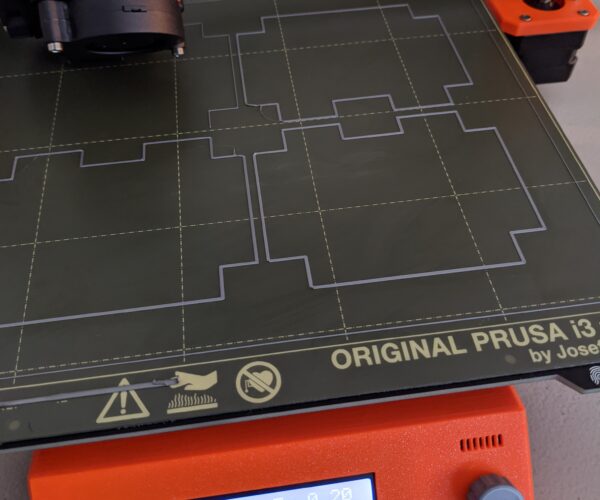

I decided to swap back to my grey Prusa PLA that I received with my printer and ran the same test. I simply cleaned the bed with IPA99% and that is it.. no other changes, but looks much much better!

- Stephen

RE: Please help! Prusament filament lifting off of print bed

Different filaments will behave differently, and yes, I've found that the silver-gray that comes with the printer is a very good base case for how a PLA filament should behave.

Assuming that your plate is truly clean and that your Z is dialed in, I'll make yet another plug for something that really helps when PLA simply refuses to stick properly. It's not a substitute for keeping the plate clean, but makes quite a difference in cases where PLA just fails to stick. Layerneer Bed Weld. Very good for small items and for the first layer of supports with small footprints.

RE: Please help! Prusament filament lifting off of print bed

@jsw

Thank you! I'll order a bottle and give it a shot.

I am currently printing with the prusament orange again right now.. *If* I can manage to get the first layer to stick, it prints phenomenally! It's just that damned first layer that drives me up a wall. I was worried as I haven't had this issue with other PLA's as of yet. I suppose I was maybe a bit naive to assume that all PLAs should behave the same. I suppose I will need to keep better notes of adjustments I need to make for each brand, etc.

thanks again for the tip!

-- Stephen

RE: Please help! Prusament filament lifting off of print bed

Some people try to sell you sand paper, others try to sell you glue. When in fact all that is needed is a little bit of TLC washing and drying the bed with soap and water.

Take the sheet to a sink, and wash it with dish soap and hot water. Scrub with a fresh paper towel until the rinse water sheets off like a freshly waxed car. Dry the few remaining drops of water with another fresh paper towel, handle the sheet only by the edges, put it back on the printer.

No alcohol is needed after soap and hot water.

An occasional acetone scrub can also help the smooth PEI sheet. After a couple months the PEI oxidizes. Acetone removes these oxides. A soap and water wash removes the film the acetone scrub leaves behind.

If it's a textured sheet it is well known some Prusa textured sheets hate all PLA - glue might be needed. Or, buy a different brand sheet. That said, soap and water has been known to remove manufacturing residue off the powder coating and help with PLA; but the PC sheet must be heat dried after it's been washed - 80c for 1o to 15 minutes.