Please help me with nylon gears

Hello guys! I am pretty new on 3d printing, just about a year with my mk3s, which is helping me a lot with many projects.Lately I am making an RC car, everything good so far.. but for the gearbox I decided to use Nylon.I have a spool of Overture Pa filament, which prints without big problems.. but with little flaws I'd love to correct.. mostly for learning and improve my knowledge about this beautiful machine.

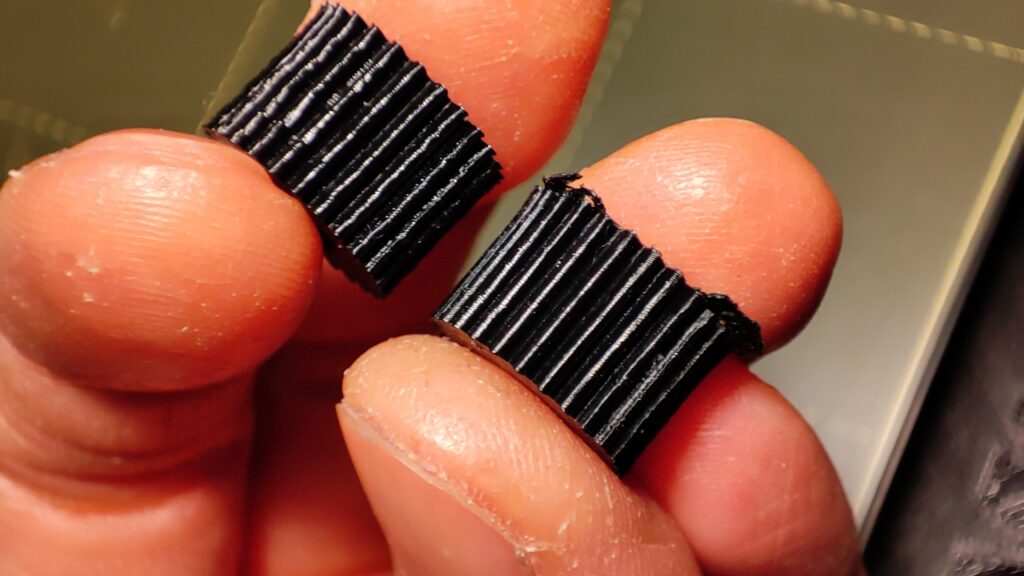

Problem is.. the gears are just a bit squashed at the base giving me the base diameter a bit bigger than the rest of the part.And I get some teeths to be imprecise, like if they were too hot when the new layer came and they moved a bit causing those defects.The gears are small.. around 10mm diameter the smallest and around 20 the biggest. For teetch they are a bit bigger than module48.It seems the bigger the gear, the better the result. I tried playing with speed and it seems the faster..the better.

I print as per manufacturer specifications: 50degC bed, and 250degC extruder.I print on the classic smooth pei sheet with help of specific magigoo glue.Oh and I am using a series X, steel tempered 0.25 nozzle.I dryed filament with filament dryer prior to printing and for the last print (big gear) I even left the whole spool in the dryer (turned on) while printing. I use a Sunlu dryer.Printer is in house and we have heaters on.. so I don't think its a moisture problem.

I attach a picture of big gear came out pretty nice but a bit squashed, and 2 attemps of smaller.. the more nicer is the one printed full speed, the less nice has been printed 40% speed.

Simplest is to use a higher elephant's foot compensation setting, carefully though as if the value is too large you may have too much overhang or even reduced adhesion.

Cheerio,

RISPONDI: Please help me with nylon gears

Simplest is to use a higher elephant's foot compensation setting, carefully though as if the value is too large you may have too much overhang or even reduced adhesion.

Cheerio,

Thank you for your answer, honestly I didn't knew about that setting! Heheh I still have to learn a lot. Thank you a lot for the hint!!! This evening I'll do some testing.

What you think about the other problem on teeths looking a bit melted/scarred/shifted?

These are quite small gears. It's possible that your belt tensions are not perfect or your smooth rods need lubrication ...

It's equally possible that the software you are using to calculate the involutes is not outputting a fine enough mesh, or even that the mesh is fine enough but it is positioned on the bed so that there is interaction between the mesh positioning and the diameter of your extrusions.

When designing my own gearing I tend to use larger cogs and teeth - and often this allows me to work in PLA which makes crisper gears.

See: https://www.printables.com/model/255791-basic-walker-walking-construction-toy

Cheerio,

RISPONDI: Please help me with nylon gears

These are quite small gears. It's possible that your belt tensions are not perfect or your smooth rods need lubrication ...

It's equally possible that the software you are using to calculate the involutes is not outputting a fine enough mesh, or even that the mesh is fine enough but it is positioned on the bed so that there is interaction between the mesh positioning and the diameter of your extrusions.

When designing my own gearing I tend to use larger cogs and teeth - and often this allows me to work in PLA which makes crisper gears.

See: https://www.printables.com/model/255791-basic-walker-walking-construction-toy

Cheerio,

Hello,

Thank you for your answer.

First of all I want to tell you the results of yesterday evening tests after checking your hint.

Elephant foot was disabled as it was set at 0.00. (I begun "writing" this new profile from a PA profile found in the Prusa slicer db), so ai tried to set it more than zero and after a couple attempts it gave me a very good result. Now the gears are nice cylindrical and no more swuashed, so.. big big thank you.

I am using so small gears because the car I am building is a replica of an old rc car.. so I need to have small gears to fit into gearbox with same sizing as stock and because I want to push myself into hard challenges to learn more.

I think rods are good since I checked not so much time ago about lubrication.

Instead the belt tension is something I just didn't think..and tonight I'll check.

Even tho.. since those gears were not done by myself but downloaded from a website I suspect about the design flaw you mentioned..

Tonight I'll check belt tensioning, and as soon as bearings will come in the mailbox I'll check the gearbox with Yesterday's gears which seem to be not bad at all. If they run without major issues.. I'll redesign them myself and try to print again.

For now.. big thank you for your support.