PLA Filament problem - extruder stops extruding filament

Hello to all,

I'm testing a new PLA filament (SunTop - PLA Silk).

I've printed different tree-frogs but every time, on different moments, the extruder stops to extruding filament.

Unloading the filament, it doesn't come out. I need to open the extruder from the side, cut the filament and then remove it.

The end of the filament gets fat and it doesn't pass in the teflon tube. So the filament gets maybe ripped off and the extruder stops to print.

Here some pictures:

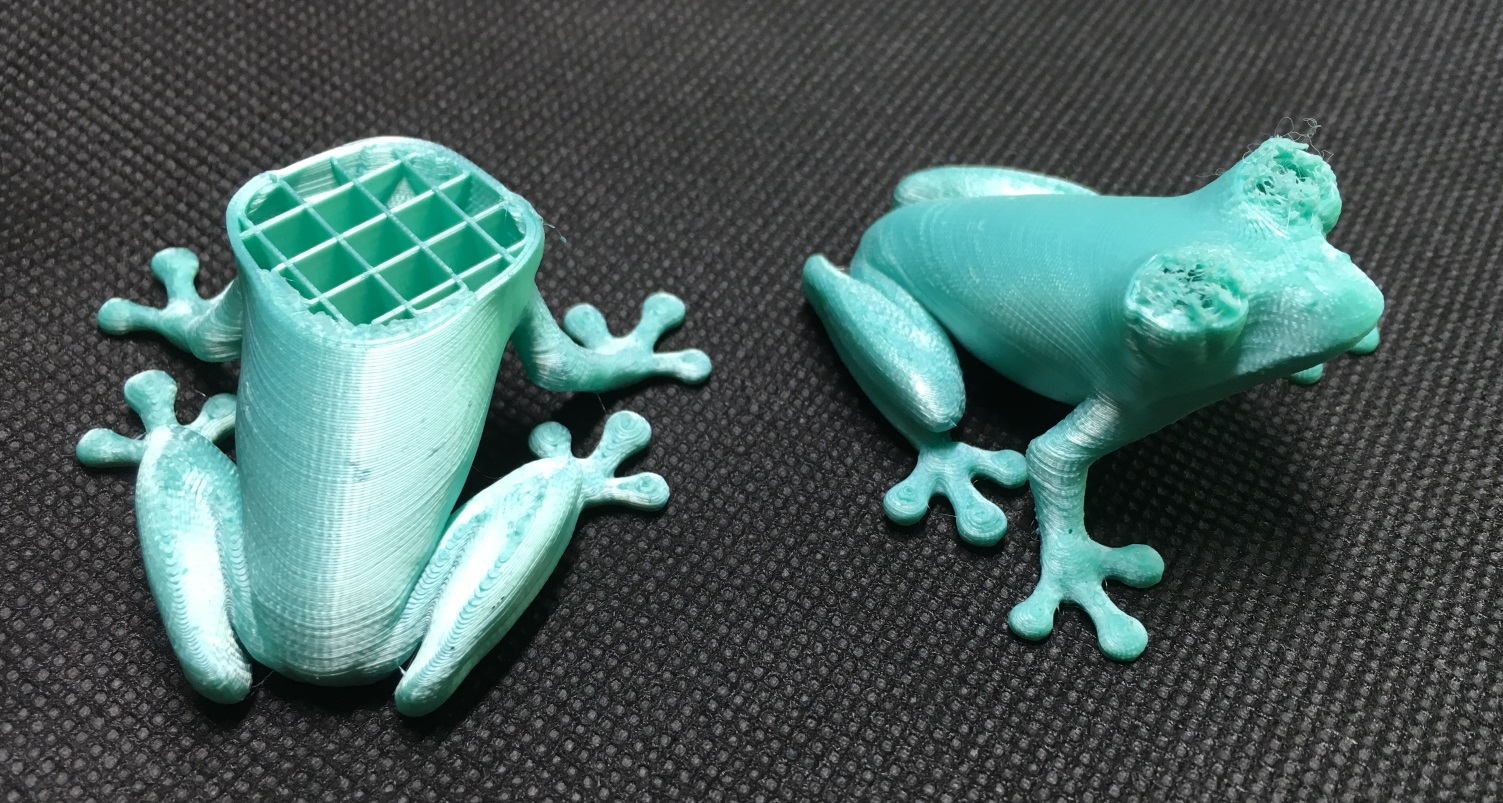

Two frogs not competed due the extruder stopped to print:

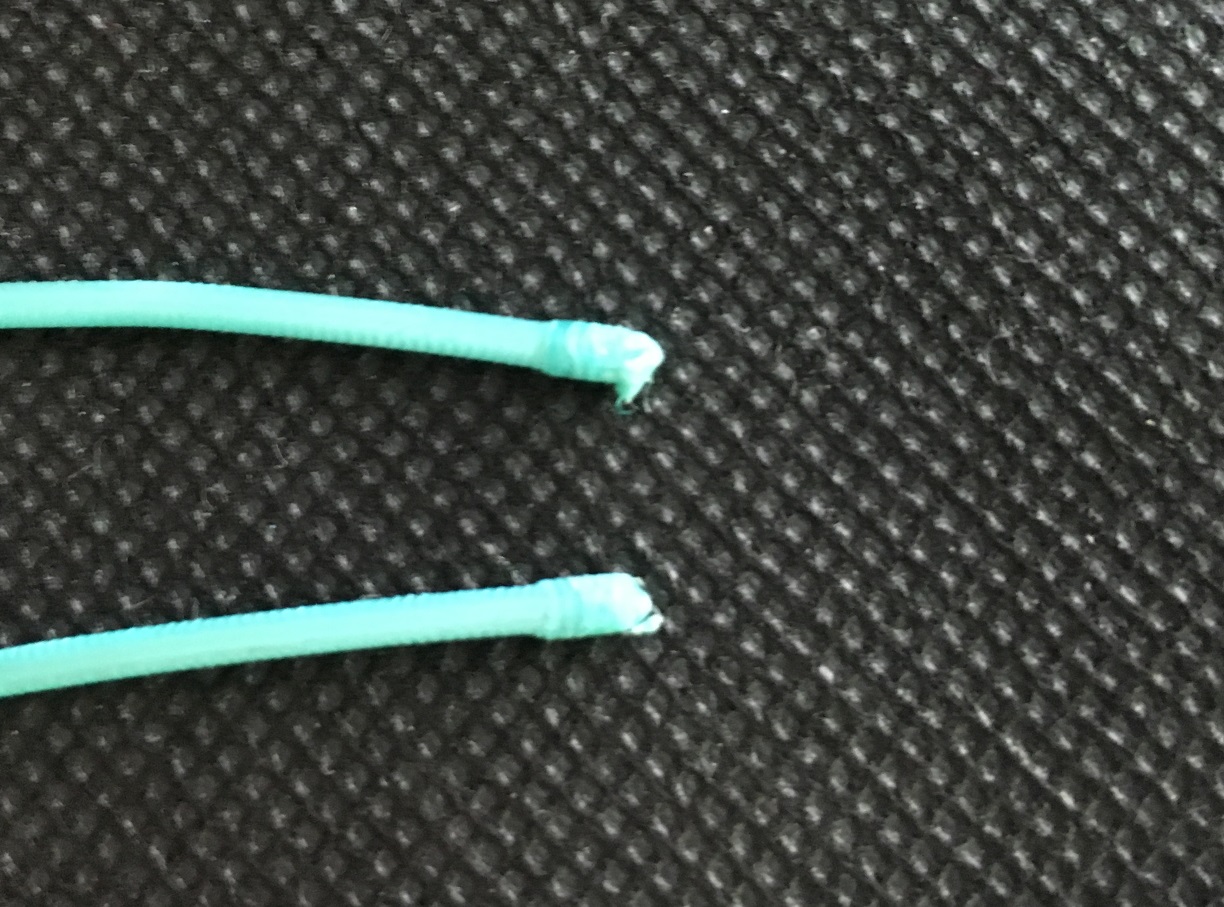

The end of the filament after taking it out from the extruder:

You can notice the end is bigger.

This PLA is printed first at 210°C (60 bed), then I've tried it at 200 - 40 as well.

At 200°C (the frog on the left) the surface is even cleaner.

Then I've used the SAME gcode to print the frog with a different PLA (other brand) and it worked... so the problem is on the filament.

Could it be because the room is too hot?

The printer is in a enclosure. Well, actually the enclosure door is open, but in the room, there are more or less 30-31°C, it's hot!

Thanks for the support!

Simon

Re: PLA Filament problem - extruder stops extruding filament

[...] Could it be because the room is too hot?

Heat will certainly add to the heat problems! A lot of the recent posts coincide with the hot summer months and/or enclosure use. Prusa has issued an extruder design that is intended to improve cooling, but even that will have limits. An open enclosure door might not be enough to allow airflow. You could try adding cooling or printing the new extruder parts, but it does sound like using another filament will work for you.

The printer is in a enclosure. Well, actually the enclosure door is open, but in the room, there are more or less 30-31°C, it's hot!

The fails seem to happen most frequently at detail areas with lots of retractions. Retractions add to the extruder motor works, which generates heat, which can creep into the extruder mechanism. You could try minimizing the retractions or slowing down if you are using the default Prusa speeds for infill.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: PLA Filament problem - extruder stops extruding filament

[...] Could it be because the room is too hot?

Heat will certainly add to the heat problems! A lot of the recent posts coincide with the hot summer months and/or enclosure use. Prusa has issued an extruder design that is intended to improve cooling, but even that will have limits. An open enclosure door might not be enough to allow airflow. You could try adding cooling or printing the new extruder parts, but it does sound like using another filament will work for you.

The printer is in a enclosure. Well, actually the enclosure door is open, but in the room, there are more or less 30-31°C, it's hot!

The fails seem to happen most frequently at detail areas with lots of retractions. Retractions add to the extruder motor works, which generates heat, which can creep into the extruder mechanism. You could try minimizing the retractions or slowing down if you are using the default Prusa speeds for infill.

Hello!

I've downgraded all speeds to 40mm/s as descrived in product specs.

Initially I was thinking the problem was at the teflon tube heigth, but, looking the filament near, I've noticed the hobb-goblin have marked the filament for approx 7,5cm, it means, the filament was pushed down until the extruder. The UNLOAD is not working, maybe, because, as soon the end of the filament reaches the hobb-goblin during unload, it doesn't pass through. So I need to open the right side, cut the filament, remove it and then I'm able to unload it.

I've noticed in addiction that during the print, as soon the extruder stops to extrude, the nema motor step which pushes the filament down, seems is jumping steps, like it's skipping or sliding on the filament...

Maybe always a temperature problem? 🙁 The extruder is clean, because other filament works!

Simon

Re: PLA Filament problem - extruder stops extruding filament

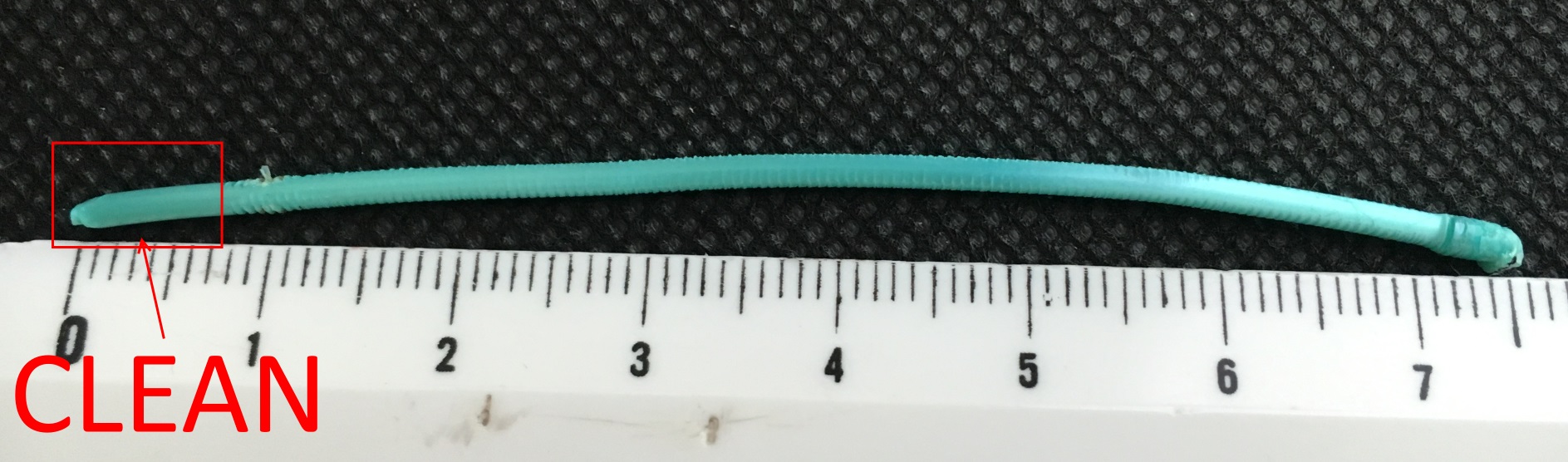

Here the complete filament I've cutted to remove it from the extruder:

In fact the most left part of the filament is much more grinded, the hobb-goblin has scratched it until I've stopped the print.

Simon

Re: PLA Filament problem - extruder stops extruding filament

What printer are you using?

I am tempted to say slacken the tension on the extruder and increase temperature. Both.

Bill

Tagaytay City, Philippines

Founder member of Philippines Prusa Printer Owners FB Group

Sponsor Pillars of God Academy in Bacoor

Re: PLA Filament problem - extruder stops extruding filament

What printer are you using?

I am tempted to say slacken the tension on the extruder and increase temperature. Both.

I'm using MK3. I've printed the R3 parts, maybe, if it's a temperature problem, I'll redice it so... and slacken the tension? I would think that if the filament is not able to pass, the tension should increased, the hobb-goblin should push with more force on it, not?

Thanks, Simon

Re: PLA Filament problem - extruder stops extruding filament

I'm using MK3.

MODERATOR NOTE: This topic was originally posted in the Mk2 forum.

Unfortunately, if you post Mk3 problems in the Mk2 forum, you can waste everyone's time because they are different printers with possibly different solutions.

I will move this post the the correct forum.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: PLA Filament problem - extruder stops extruding filament

I'm using MK3.

MODERATOR NOTE: This topic was originally posted in the Mk2 forum.

Unfortunately, if you post Mk3 problems in the Mk2 forum, you can waste everyone's time because they are different printers with possibly different solutions.

I will move this post the the correct forum.

Peter

OF COURSE!

I was sure I've posted it on the MK3 forum, my fault, sorry.

Thanks Peter.

Simon

Re: PLA Filament problem - extruder stops extruding filament

Any update?

I've been having this same problem for almost a month now (MK3). Seems to only happen with PLA - I've got three different spools that it happens to. I don't see this issue at all with PETG, so it isn't a bad spool or anything. I printed off the new extruder body that is supposed to improve cooling, but no dice. I've tried several different tensions on the gears ranging from set according to instruction, barely engaged, and extremely tight. Failures at each.

I've been seeing this issue pop up with multiple users, so it would be nice if we can get some kind of official response on it, possibly an investigation.

Re: PLA Filament problem - extruder stops extruding filament

Actually no news, I'm planning to try the R3 parts update next week.

Meanwhile, GREAT avatar, I love Daft Punk 😀

Re: PLA Filament problem - extruder stops extruding filament

Actually no news, I'm planning to try the R3 parts update next week.

I've followed several similar-sounding threads in the last week, each of which ended with proper tightening of the extruder tension screws. How tight are yours? I generally print most materials without issue when the screws are tightened to the point that they protrude roughly 1mm from the left side cover.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: PLA Filament problem - extruder stops extruding filament

Actually no news, I'm planning to try the R3 parts update next week.

I've followed several similar-sounding threads in the last week, each of which ended with proper tightening of the extruder tension screws. How tight are yours? I generally print most materials without issue when the screws are tightened to the point that they protrude roughly 1mm from the left side cover.

Hello,

Does it mean the screws that are fixing the hobb-goblin to the filament?

I'll check it this evening.

Do you think it's too much tighten or too low that causes those issues?

Thanks, Simon

Re: PLA Filament problem - extruder stops extruding filament

[...] Does it mean the screws that are fixing the hobb-goblin to the filament?

The tension screws for the hobbed gear, yes.

[...] Do you think it's too much tighten or too low that causes those issues?

Most of the problems seem to come from having it too loose, but having it too tight can also cause problems. I tighten mine so the tops of the screws are protruding out from the left cover less than 1mm. A little looser or tighter should be fine. Also make sure the idler gear on the flip-up cover on the right (the part that those screws hold down) is able to rotate freely. It can come loose and jam.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: PLA Filament problem - extruder stops extruding filament

[...] Does it mean the screws that are fixing the hobb-goblin to the filament?

The tension screws for the hobbed gear, yes.

[...] Do you think it's too much tighten or too low that causes those issues?

Most of the problems seem to come from having it too loose, but having it too tight can also cause problems. I tighten mine so the tops of the screws are protruding out from the left cover less than 1mm. A little looser or tighter should be fine. Also make sure the idler gear on the flip-up cover on the right (the part that those screws hold down) is able to rotate freely. It can come loose and jam.

Ok, thanks, I'll give it a look.

Do you have upgraded to R3 parts? Just to know. I'm following the other thread, in which is difficult to understand if the dyson version is ok or not.

Re: PLA Filament problem - extruder stops extruding filament

No. I am not having any issues, and I'm waiting to see how that all turns out before changing my functional printer. I've read reports about increased noise (something I care very much about) and questionable air flow.

[...] Do you have upgraded to R3 parts? Just to know. I'm following the other thread, in which is difficult to understand if the dyson version is ok or not.

After following a lot of the threads here, I'm convinced at least some of the "extruder issues" can be fixed with slicer settings or basic system maintenance, so I'm in no hurry. For some users with specific issues, it might make good sense to update. I'm going to wait until the next iteration.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: PLA Filament problem - extruder stops extruding filament

No. I am not having any issues, and I'm waiting to see how that all turns out before changing my functional printer. I've read reports about increased noise (something I care very much about) and questionable air flow.

[...] Do you have upgraded to R3 parts? Just to know. I'm following the other thread, in which is difficult to understand if the dyson version is ok or not.

After following a lot of the threads here, I'm convinced at least some of the "extruder issues" can be fixed with slicer settings or basic system maintenance, so I'm in no hurry. For some users with specific issues, it might make good sense to update. I'm going to wait until the next iteration.

Sounds good 😉

Re: PLA Filament problem - extruder stops extruding filament

I´am having the same issue with the PLA filament too.

The only way to avoid the filament start to jam is to set the retraction lenght to zero and increase the temperature (220°C). Of course such a setting makes the printed parts to look with a lot of stringing.

When I pool the filament out of the extruder, the front part shows an increased diameter (but offset from the center). This is because (I guess) the material is building up (cold flow) in the heat break zone during retraction. The strengh on the walls of the teflon tube is not enough to avoid the filament to increase on it´s diameter at the chamfered area. With an increased diameter the filament won´t move any more and the jamming starts 😯

The extruder motor gets hotter than usual, but this is because the jammed filament doesn´t allow it to turn as usual.

The only "good" PLA that has worked without any issues until now (for any geometry) was the PLA silver deliverd with the assembly kit.

I´am also not using an enclosure.

Prusa i3 MK3.

PLA is from JANBEX (all three colors with the same phenomena)

Re: PLA Filament problem - extruder stops extruding filament

Having the same issue as well. I've not really been able to get much in the way of a whole print since I got this printer (of the 40+ attempts, I have 3 complete prints), and support has stopped responding, so I'm somewhat at a loss.

Eventually, the filament just stops extruding. It ACTS like a jam, though. I look in the extruder gear area, and there's powdered filament bits everywhere from where it's ground. But I can manually push filament out without any issues. And the next print starts up fine... it just... stops after about 60% or so of a print.

I've done cold pulls to no avail. I've done everything I can to adjust tension on the idler -- harder or weaker doesn't seem to matter. The idler itself spins freely.

Re: PLA Filament problem - extruder stops extruding filament

I know you've done a lot of this, but here's my standard list of things to check:

[...] I've done cold pulls to no avail. I've done everything I can to adjust tension on the idler -- harder or weaker doesn't seem to matter. The idler itself spins freely.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: PLA Filament problem - extruder stops extruding filament

I know you've done a lot of this, but here's my standard list of things to check:

[...] I've done cold pulls to no avail. I've done everything I can to adjust tension on the idler -- harder or weaker doesn't seem to matter. The idler itself spins freely.

I've tried everything short of getting someone to reprint me the entire assembly and buying all new parts for the extruder.

Spins just fine in both directions. No sticks.

Nope. Not yet, anyway.

This is indoors in a bedroom. Nowhere near that.

SD card only.

It's random, really. Details sometimes, but also just big, straight lines and fills.

Currently, any material I'm trying. PLA, XT, HTPLA, PETG

I've tried slowing things down both with the LCD control and in Slic3r.

Flows cleanly. Nice, straight lines and no pigtailing.