PLA extrusion problem

My Prusa MK3S started heaving problems with extruding PLA.

With longer prints (3 hours or more) extruder starts loudly "skipping". When i pause the print, filament is blocked and cannot be loaded through nozzle. When I unload the filament, it has expanded diameter, so it cant get through nozzle. When I cut that end, it prints for 1-2 hours until next issue.

Material is Prusament PLA and PM PLA.

Printer is in enclosure made from Ikea table, I print PLA with doors open, and it works for 2 years without issue.

Can someone help me with this? Has this happened to someone before?

RE: PLA extrusion problem

Could be heat creep - the PLA starts melting above the heat-break inside the extruder body. That's the most common "extruder clicking" issue. I'm going to guess you are printing PLA inside of an enclosure. Open the door - you can't print long PLA prints inside of a closed enclosure.

RE: PLA extrusion problem

The skipping is a back pressure issue - if you're using unchanged settings then:

Clean dust and debris from the bondtech gears with a stiff brush.

Try tweaking the extruder idler screw tension.

Try printing 5 deg hotter or cooler.

Clean the print fans and make sure the air flow is unobstructed.

Listen for popping and creaking sounds as the filament extrudes, damp filament makes little steam explosions and wastes heat, dry the filament if it's supect.

Check your ptfe extruder tube is undamaged. Change if suspect.

Inspect your nozzle, is it badly worn? (as the tip wears back the resistance changes altering the pressure.)

Cheerio,

RE: PLA extrusion problem

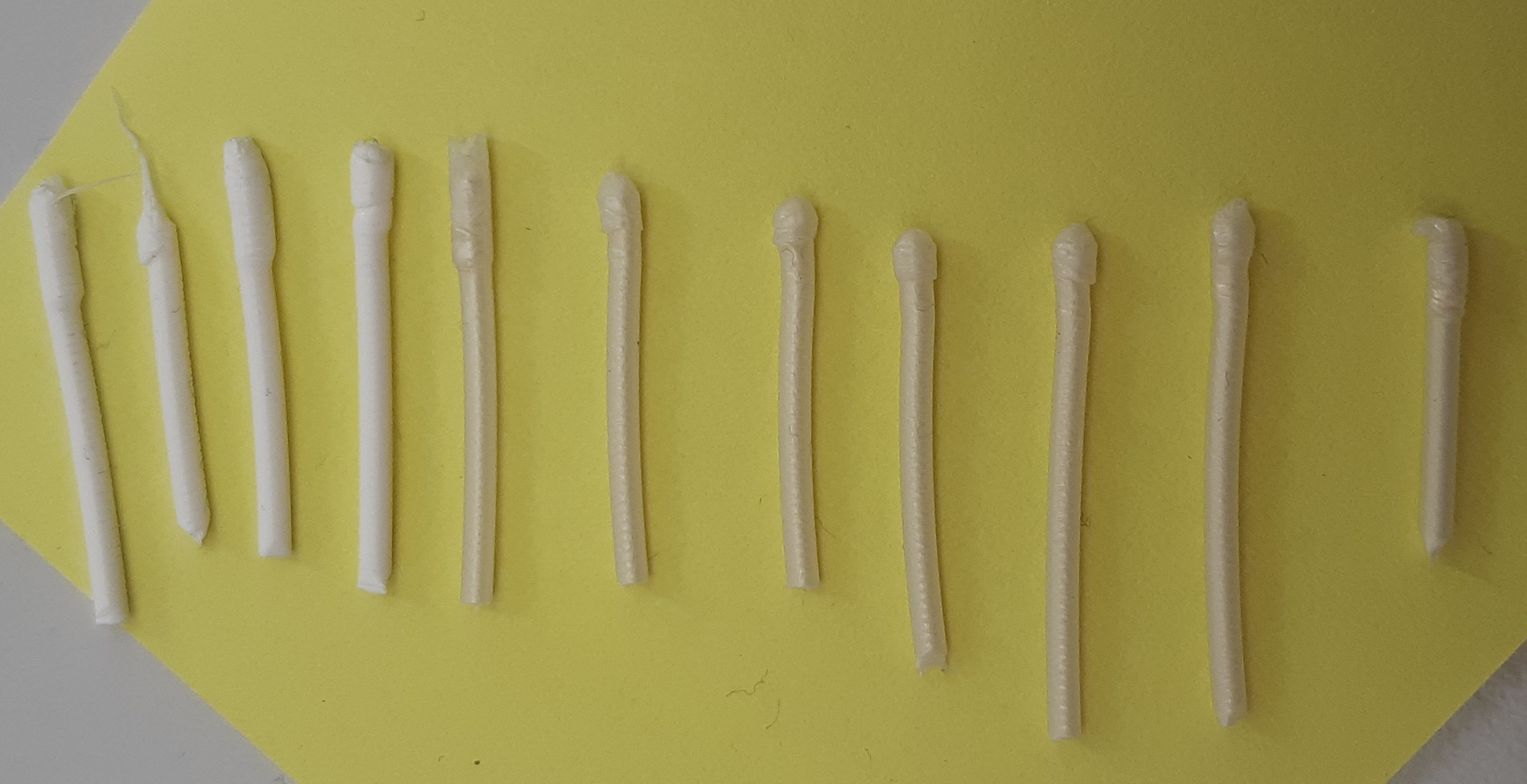

Try a different spool of PLA. I recently purchased Pearl Blue PLA Prusament and tried to print a small object with it. It failed no matter what slicer options I chose. Finally, I switched filaments. See results attached. The Pearl Blue failed many more times than pictured. The other filaments each printed first time OK.

RE: PLA extrusion problem

As we move into the summer months, expect to see a lot more of these sorts of issues. PLA is a low-temperature filament, and it's easy to get the printer up to temperatures where softening PLA causes a problem.

First thing is to confirm that the ambient temperature your printer is working in is not exceeding 40C/104F. The Mk3 uses an air-cooled hotend that is rated to 40C ambient temps. Above that, and the cooling efficiency drops. Accumulated heat can lead to a variety of problems. After that, there are a number of possible remedies. I've tried to compile the various "extruder skipping", "heat creep", and related problems into notes pages here. You might want to read through that page and see if you spot anything that applies to your setup.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan