PETG Printing

Hello,

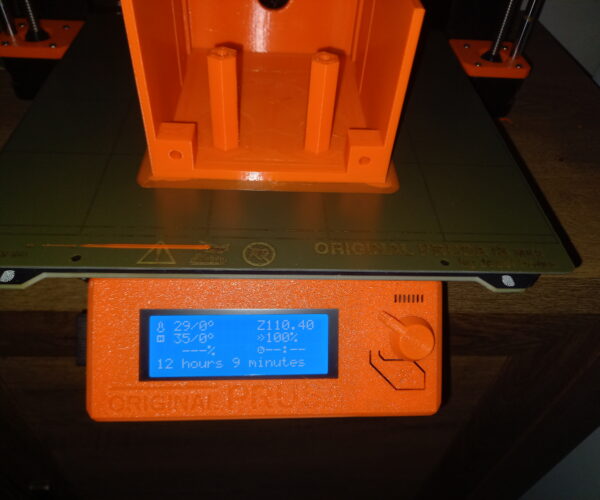

I recently tried printing with PETG, but during the print the PETG warps a bit in the corners  Is this due to improper adhesion? Afterwards when I take the print off the PEI sheet is raised a bit so I was thinking this is the problem.

Is this due to improper adhesion? Afterwards when I take the print off the PEI sheet is raised a bit so I was thinking this is the problem.

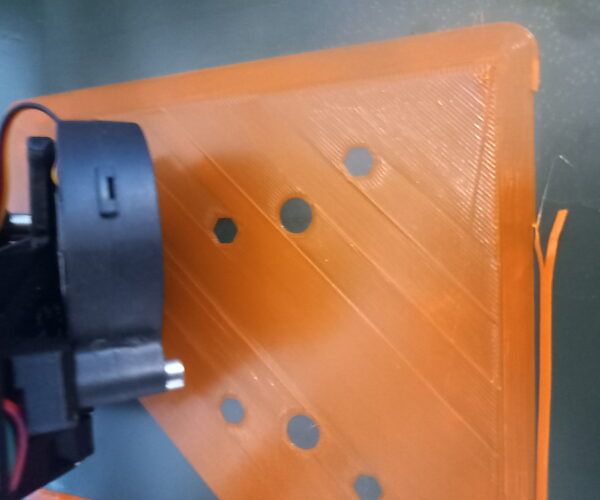

Another thing I have seen recently was that I have thicker lines on my print after features e.g. a hole

I am using Prusament PETG, the first layer is printed at 10mm/s, the nozzle has a temperature of 350 degr. C, the bed has a temperature of 90 degr. C. I print the whole print with these temperatures. Are these thick lines after features because of overextrusion or is it because of the slicer(PrusaSlicer)?

RE: PETG Printing

The print will conform to minor irregularities on the surface of the sheet. That blemish on the sheet could also be from the coating separating from the steel sheet.

Did you use a release agent? It's always advisable when printing with PETg on the smooth sheet. The included glue stick will work. The Layerneer Bed Weld will give a thinner and more consistent coat than the glue stick will. It will also help with adhesion, thus controlling warping.

If you do have an adhesion issue with PETg, you should check your Z calibration as well, as PETg usually has no issues sticking to and remaining stuck to a clean sheet. PETg, if anything, tends to stick too well.

RE: PETG Printing

The blemish on the print wasnt there before the printing and as you said im pretty sure its the pei sheet seperating from the steel sheet, but was this caused by the PETG warping or did the sheet warp the PETG?

I didnt use any release agent and because of that it might have adhered too well, but when I tried a window cleaner it wouldnt adhere to the sheet at all.

When I printed some smaller parts in PETG before I had the same issue with the pei sheet a bit, but I had alot of trouble getting the print off the sheet because it adhered too well.

I will try some glue and see if the pei sheet wont let loose when printing with PETG.

RE: PETG Printing

Back when I was unfamiliar with printing on the PEI sheets, I ruined one side of a smooth sheet by getting impatient and using a metal kitchen implement to pry off a sticking ABS print. I did not use a release agent, and I did not wait for it to cool down to almost room temperature before removing. A few pieces of the coating actually pulled off with the print. Lesson learned the hard way.

Had I simply waited for it to cool completely, it probably would have come off without damaging the sheet. There's a learning curve to printing on the Prusa sheets, and although they are generally durable, they are not as rugged as the rigid glass plates on some other machines.

RE: PETG Printing

In my experience the thicker lines is caused by the print direction change in Rectlinear bottom infill pattern. The next PS version 2.3.0 has Monotonic pattern that only prints in one direction (you can try the beta 1 from GitHub).

I print a lot of PETG and the bobbles forming on the smooth PEI sheet is normal and will go away again over time.

Too much windows cleaner on the smooth PEI sheet will prevent holding the part during print. I use diluted windows cleaner and just apply a thin coat before every print with a sponge.

If you have a textured print sheet, I will recommend that over the smooth sheet as it only needs cleaning in warm water and soap from time to time.

Have a look at my models on Printables.com 😉