PETG printing problem with screw threads

I have been printing with PLA for several years designing a medical device. As I approach the end of design and the beginning of beta units, I decided to reexamine the best filament for this device. PLA's biodegradable and toughness characteristics don’t seem to be the best for this device. So, I decided to try PETG. Everything seems to print OK, except screw threads - the hole/female, not so much the male/screw part.

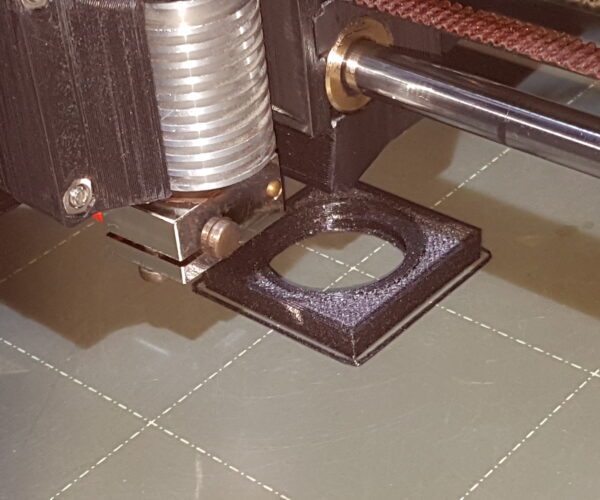

When making the circle on a screw thread, the filament does not stick and goes off into the air. The pic below is a 1 in. dia screw hole printed at the bottom of a part. It is parallel to the print bed. This is the worst of all the prints - and the latest. You can see the first layer is OK, and the rest of the object printed fine. It is just this screw thread that is bad.

I have tried raising the extruder temp, thinking if the filament is softer, it will stick and follow the contour. I am using the standard MK3 PETG profile with the print temps set to 1st layer = 230, others = 245, bed = 85, then 90.

Maybe the angle of the thread exceeds the capability of PETG.

RE: PETG printing problem with screw threads

Hmm, the quality is low around that screw hole. Did you use supports?

--------------------

Chuck H

3D Printer Review Blog

RE: PETG printing problem with screw threads

No, I didn’t use supports. Will have to try that. Note: the threads on the male screw are much better.

RE: PETG printing problem with screw threads

I have been printing with PLA for several years designing a medical device. As I approach the end of design and the beginning of beta units, I decided to reexamine the best filament for this device. PLA's biodegradable and toughness characteristics don’t seem to be the best for this device. So, I decided to try PETG. Everything seems to print OK, except screw threads - the hole/female, not so much the male/screw part.

When making the circle on a screw thread, the filament does not stick and goes off into the air. The pic below is a 1 in. dia screw hole printed at the bottom of a part. It is parallel to the print bed. This is the worst of all the prints - and the latest. You can see the first layer is OK, and the rest of the object printed fine. It is just this screw thread that is bad.

I have tried raising the extruder temp, thinking if the filament is softer, it will stick and follow the contour. I am using the standard MK3 PETG profile with the print temps set to 1st layer = 230, others = 245, bed = 85, then 90.

Maybe the angle of the thread exceeds the capability of PETG.

I don't want to speculate now but would you consider providing the STL file (zipped)? I would like to test it on the Mini with the new E3D V6 hotend (only the thread).

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: PETG printing problem with screw threads

@karl-herbert

Karl, the file is large (8hrs), so I don’t think you want that. I will make a smaller file of just the threaded hole and post it.

I am at the beginning of a 4 hr print now, so it will take a while.

RE: PETG printing problem with screw threads

@ben-g16

No problem. The Mini is my testing machine and there is enough filament and time for such experiments. Smaller part, only with threaded hole is a good idea!

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: PETG printing problem with screw threads

Maybe you could use metal inserts in threads, youtube has a movies about this.

RE: PETG printing problem with screw threads

@peter-m26

Peter, you are right, but I expect a 1 in/25mm Nutsert/PemNut would be very expensive. I am trying to avoid such one-off expensive parts. I could buy a 1 in tap and rethread the hole, which I do with small ones, but it cost $135, so I am looking at all the alternatives before I decide.

The hole doesnt have to be pretty (it is on the bottom), but it has to be useful.

RE: PETG printing problem with screw threads

Karl, here is the screw hole.

RE: PETG printing problem with screw threads

@ben-g16

Thanks - I will give it a try the next days 👍

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: PETG printing problem with screw threads

I print screws/screw holes all the time in PETG. A few random thoughts in case you haven't already had them.

- I never use supports - tend to be hard to remove and useless given the typical support clearances versus the thread sizes.

- How did you create the screws? I use Fusion and use their holes. Generally I try not to select a very fine pitch since that makes everything tighter. For most screw types in Fusion you have some choices of thread pitch.

- I do tend to print a bit on the hot side which gives better adhesion.

- I generally add a bit of clearance in the design after the screw is done via a press/pull on the 4 screw faces (typically on the male since it is easier). I use about .1-.2 mm to get a screw that is easier to turn but still holds well.

RE: PETG printing problem with screw threads

@ben-g16

I just did this quickly. Printed with my just modified Prusa Mini (E3D hotend) with Prusa PLA galaxy black:

The project file is exported from the Mini, but you can use the print parameters for MK3.

project file: 1 in screw hole

good luck 👍

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: PETG printing problem with screw threads

Kevin,

I just printed a “useable” 1 in hole and plug. I did two things: 1) raised the extruder temp to 250 (250max), and (2 made the plug 5% smaller in XY, but not Z.

I had to use needle nose pliars to pull off strings that didn’t conform, but I could get the two parts to screw together. I may try again at 255C to see what happens.

When I am doing PLA screw holes with metal screws, I oversize the holes (XY) by 10%.

BTW, parts of the PETG extruder housing melted away when I printed my “S" upgrade parts last year using Prusa’s PETG sent for the purpose..

RE: PETG printing problem with screw threads

@karl-herbert

Karl, I have no problem printing screw/hols with PLA. It is just PETG that is causing the problem.

RE: PETG printing problem with screw threads

@ben-g16

1st test with Extrudr PETG:

Certainly still optimizable, but stringing can probably not be avoided completely.

Printed with the Prusa Mini. The MK3 is currently under repair.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: PETG printing problem with screw threads

@karl-herbert

I have gotten much better results on the screw by using the max extruder temp for the filament (255C). I havent printed a hole yet.

I am also designing a thread with a 45º angle, which might better match the over hang capabilities of PETG. Will see.

RE: PETG printing problem with screw threads

@ben-g16

A photo would be a great thing. If the thread does not have to comply with the standard, it is of course useful to change the flank angle from 55 to 90 degrees.

But I am pleased for you that it works now 👍

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: PETG printing problem with screw threads

I print screws/screw holes all the time in PETG. A few random thoughts in case you haven't already had them.

- I generally add a bit of clearance in the design after the screw is done via a press/pull on the 4 screw faces (typically on the male since it is easier). I use about .1-.2 mm to get a screw that is easier to turn but still holds well.

Please tell me more about this. Do you do this in Fusion360? I am using the standard thread tool, and applying ANSI 1/4-20 threads to a nut. I find that larger threads are easier to do. This smaller thread is printing fine.. but way too tight for screwing onto a bolt. .20 layer height with PETG has perhaps too much extrusion width?

3/8-16 threads work ok with PLA at .15 layer height.

RE: PETG printing problem with screw threads

ah. yes, push/pull ('Q') in Fusion360. I like it. I think this will save the day for me!

RE: PETG printing problem with screw threads

I do a lot of printed threads.

In PETG, especially for female threads, I find dropping the layer height to 0.15 sorts the issue you are experiencing.

Depending on the model, I either print the whole model at 0.15 or just set the layer height via the variable layer height tool for thenfemalenthread portion. The latter can be frustrating because the implementation of that tool sucks - even in 2.3.0 Beta 2.

It's fiddly, time consuming and quite difficult to be accurate and consistent.

Prusa need to significantly simply it by allowing you to define a specific layer height and set what layers it applies to.