PETG Print crackling after being printed, shrinking, cracking. Solution?

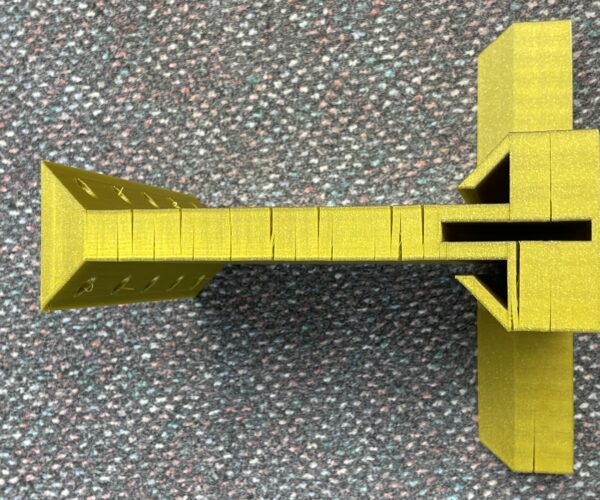

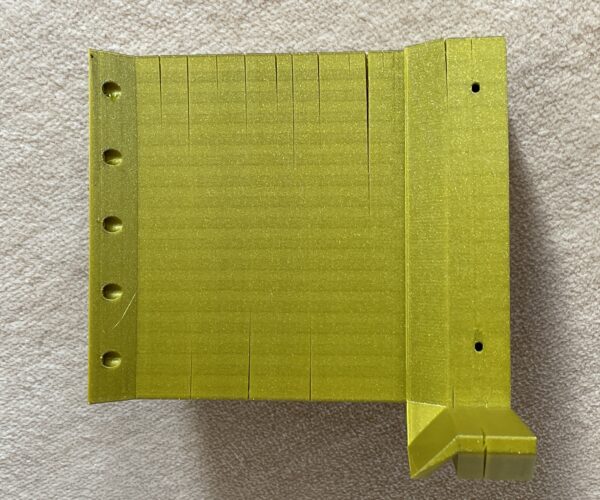

I have a large PETG print (250 x 200 x 210) that prints just fine. While printing it looks perfect.

After the print is finished and begins to cool it starts making crackling sounds and begins to pull apart at the layers. Over the next 5 to 6 hours the separations continue to be more severe and the crackling continues.

I assume this is because of internal tension and shrinkage.

Is there a straightforward solution, or is this inherent in PETG?

Best Answer by Peter M:

Print in a enclosure could help, and let the print cool down in the enclosure.

Let no cold air hit the print wen printing.

Do a temp tower to see what is the best temperature.

It could the filament, dry the filament so no water is inside the filament.

Try different filament.

RE: PETG Print crackling after being printed, shrinking, cracking. Solution?

Print in a enclosure could help, and let the print cool down in the enclosure.

Let no cold air hit the print wen printing.

Do a temp tower to see what is the best temperature.

It could the filament, dry the filament so no water is inside the filament.

Try different filament.

RE: PETG Print crackling after being printed, shrinking, cracking. Solution?

Wow, sounds like I could waste a LOT of time fumbling around in the dark on this one.

I have and diligently use a dry cabinet at 27%RH. It is Prusament PETG.

Beyond that all of the other things you suggest sound to me like this:

“Yeah, printing a large PETG really doesn’t work unless you want to make mods to your setup and spend a lot of time experimenting and fiddling. Some have actually gotten it to work, but if you just want to print that size of PETG simply, it’s not going to happen.”

I’m one of those people that drives a Honda and doesn’t spend Saturday afternoons installing aftermarket mods. I buy Honda for the same reason I bought Prusa: I want it to just work reliably. And, for the most part it does... just not on Max-sized PETG, apparently.

RE: PETG Print crackling after being printed, shrinking, cracking. Solution?

Save your parts and settings in a 3MF project file, zip it up, and attach it to a reply here so we can see your settings. I print large PLA pieces and don't get delamination after printing. Has this happened with multiple spools? What brand of PETG are you using?

With PETG, printing hotter helps with inter-layet adhesion. Avoid cooling if possible.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: PETG Print crackling after being printed, shrinking, cracking. Solution?

you didn't give us much information to go on, but I'm going to say try turning up the temp on the hot end. you should get better layer bonding.

The Filament Whisperer

RE: PETG Print crackling after being printed, shrinking, cracking. Solution?

I am not sure what more information to provide. I am attaching the model and Code for you to have, if you wish.

The PETG material I am using is Prusament brand Prusament manufactured by Prusa.

I am using the default settings for Prusament on an i3Mk3+ printer.

Toom temperature is 20c/70F. Prusament is stored at 27% RH and the room RH is 49%.

It is notable that the model was minimally cracked during the printing process. Over the course of the next six hours it could be heard crackling and the cracks started appearing and getting wider.

Since I print functional units, my goal is not the joy of tinkering with the printer for a weekend. I find that to be about as interesting as tinkering with a tape dispenser all weekend long. So my attitude is mostly the same as with a broken tape dispenser...move on and solve the problem another way.

Nevertheless, if there is a straightforward, proven, reliable solution then I am open to learning and making it work. I just don't want to sped much time on this digression from my task at hand.

This system would not allow me to share the model because the code is over 10mb in size. Here is a link that will be valid for approximately 7 days:

RE: PETG Print crackling after being printed, shrinking, cracking. Solution?

@seattledavid

If your looking for a point and click make product button you haven't found one in FFF/FDM.

3D printing requires knowledge and experience, learning is the straightforward, proven, reliable solution. if you can't be bothered why would others bother to help.

I would move on and find another solution,

Good Luck to you

The Filament Whisperer

RE: PETG Print crackling after being printed, shrinking, cracking. Solution?

You sound awful busy. I'm busy too so don't have time to deal with downloading files from an unknown web site. If you'd care to save your part and settings off in a 3MF project file, zip it up, and attach it to a reply here as already requested above, maybe somebody can find the time to check it out. We're all very busy though, and working on somebody else's tape dispenser is no more exciting for us. Perhaps you'll have more time to help us help you at some point in the future

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: PETG Print crackling after being printed, shrinking, cracking. Solution?

3D printing requires knowledge and experience, learning is the straightforward, proven, reliable solution. if you can't be bothered why would others bother to help.

I would move on and find another solution,

Good Luck to you

That comment is just a little snarky, don't you think? Brushing your teeth requires knowledge and experience, as does using a screwdriver or a microwave. But most tools require a reasonable learning curve and have reasonable predictability.

I keep three Prusa machines pretty busy around the clock printing my designs. I don't know how many unique designs I have done and printed, but it is many hundreds by now. They range from birdhouses to trash can mounts to switch brackets to artwork. It's pretty rare that I run into such difficulties as I have experienced with this particular print.

Even if your message was that this particular print is problematic and is unlikely to be easy to get to print as desired, I think it could have been said just a little more civilly. [IMHO]

RE: PETG Print crackling after being printed, shrinking, cracking. Solution?

You sound awful busy. I'm busy too so don't have time to deal with downloading files from an unknown web site. We're all very busy though, and working on somebody else's tape dispenser is no more exciting for us. Perhaps you'll have more time to help us help you at some point in the future

My expectation was only that if somebody had a quick solution ("Hey, I have seen that and you just need to kick the machine in this spot") that would be wonderful. I didn't expect that anybody would spend much time debugging this issue. I have alternatives, namely, breaking it up into several pieces and making the backbone out of wood or aluminum.

So I was only hoping there was a well known, easy, straightforward known answer to this class of problem. That's all. Seems like it is a fiddly, complex problem...and knowing that is enough for me. I only need four of these brackets, and I can design a hybrid material design in less time than iterating this 18-hour print.

So you have helped me a lot to know that it's not a well known, simple, straightforward (or at least obvious) fix.

RE: PETG Print crackling after being printed, shrinking, cracking. Solution?

PETG is not difficult to print with if you follow the usual recommendations and don't make changes to the provided profiles.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: PETG Print crackling after being printed, shrinking, cracking. Solution?

@seattledavid

Gcode is useless for diagnosis, it merely preserves the symptoms. Zip a 3mf file and we may find the cause.

Cheerio,

RE: PETG Print crackling after being printed, shrinking, cracking. Solution?

I wonder if this is another case of @SeattleDavid confusing the Prusa PETG and Prusament PETG profiles. The Prusa PETG profile prints at 10-20C cooler than the Prusament PETG preset. Printing PETG at 230C instead of the manufacturer's suggested 240-250C would certainly explain the delamination.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: PETG Print crackling after being printed, shrinking, cracking. Solution?

Hard to help someone who doesn't want help. Here's a quickie suggestion. It might be your issue. I think you are under extruding. The layers are not bonding - so you probably can pick the thing up, wrench it in your hands and it cracks into shreds. That's under extrusion.

There's your hint.

RE: PETG Print crackling after being printed, shrinking, cracking. Solution?

Looks like a combo of poor layer adhesion and cooling stress. Interesting to note that the stress cracking (if that is indeed what it is) continues long after the part should have cooled down.

RE: PETG Print crackling after being printed, shrinking, cracking. Solution?

I wonder if this is another case of @SeattleDavid confusing the Prusa PETG and Prusament PETG profiles. The Prusa PETG profile prints at 10-20C cooler than the Prusament PETG preset. Printing PETG at 230C instead of the manufacturer's suggested 240-250C would certainly explain the delamination.

You make it sound like this is an ongoing, repeating problem, or like that was ever a problem. Is it necessary to be so attacking? (Are you even aware of how attacking your innuendos are?)

On that incident from a long, long time ago I then pointed out that the Prusament PETG MMU2 profile was markedly different from the MMU2-Single profile any about 10c. So there are multiple "right" answers, or if you are that type of person, multiple "wrong" answers.

Yes, I'm using Prusament brand filament from Prusa and am using the Prusament PETG setting (and not the "single" variant") By the way the nozzle is 0.6mm, which is the one all of my machines use.

-----

The object is now is quite strong. I can wack it with a 3lb rubber mallet and it stays intact. I am unable to break it using my hands. No tendency to break or delaminate now.

I have a time-lapse of the printing and the cracking only hinted during the printing process. It was during the cooling cycle that it slowly and surely started crackling and ended up looking like it now does. And, yes, there was crackling for 5~6 hours after printing. (Most was at first, but it would click occasionally until about 5~6 hours.)

Separating from shrinkage is consistent with what I observe. The internal forces must have been very extreme.

-----

I'm honestly not all that interested in solving this problem at this point. If there was a quick and simple solution that would have been great. But I will move on to simpler, more assured solutions. It is easy to substitute the backbone with a sheet of aluminum (or even ¾" wood) and the object will be equally aesthetic and functional. I can 3d print the top mounting bracket and the bottom T-Bar. That will work just fine and I should have them done today.

While I have done hundreds of different 3d printed objects and by now have printed thousands of items I have a decent handle on the process. But I have never printed anything as large and solid as this particular print. This item was something over 600 grams of material. I don't typically need larger parts like this...I was just avoiding cutting and finishing a sheet of 6061 aluminum.

-----

It is not that I have total disinterest in learning or even in learning what caused this problem. It is that I have less than 10,000 days in which to live, I am pressed for time, there are so many areas of interest, and I must choose which are worthy of consuming one of those precious days. (I am dead serious in this way of thinking, pun intended.)

I do appreciate the help and suggestions. It is all food for thought. I was not previously aware that PETG did or could have shrinking problems. I wouldn't have suspected it from what I read. So that is good input and consideration for the future.

So thanks for your time and your suggestions. Truly.

RE: PETG Print crackling after being printed, shrinking, cracking. Solution?

I wonder if this is another case of @SeattleDavid confusing the Prusa PETG and Prusament PETG profiles. The Prusa PETG profile prints at 10-20C cooler than the Prusament PETG preset. Printing PETG at 230C instead of the manufacturer's suggested 240-250C would certainly explain the delamination.

You make it sound like this is an ongoing, repeating problem, or like that was ever a problem. Is it necessary to be so attacking? (Are you even aware of how attacking your innuendos are?)

The Prusament PETG profile uses 240-250C. Your gcode indicates you are printing Prusament at 230C. You made an earlier post in which you had mixed the two up, so this is a reasonable question. A 20C low temperature can definitely affect PETG inter-layer adhesion. If you would provide your zipped 3MF, we wouldn't have to guess as much.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: PETG Print crackling after being printed, shrinking, cracking. Solution?

The Prusament PETG profile uses 240-250C. Your gcode indicates you are printing Prusament at 230C. You made an earlier post in which you had mixed the two up, so this is a reasonable question. A 20C low temperature can definitely affect PETG inter-layer adhesion. If you would provide your zipped 3MF, we wouldn't have to guess as much.

I wonder if this isn't another case of @Bobstro confusing the Prusa i3 Prusament PETG setting with the Prusa i3 MMU2S Prusament PETG setting. (I couldn't resist mirroring your prior snarky comment, sorry) We've had this conversation already. You would be entirely correct if you weren't wrong.

The temperature default by Prusa on the i3 equipped with the MMU2S using a 0.6mm nozzle for Prusament PETG is 230c. Really. We have already talked about this.

As I said, the easiest solution is for me to move on, which I am doing. I can easily use 6061 aluminum for the backbone and make the top and bottom out of PETG.

I didn't previously include the 3mf file because (a) I didn't have it, (b) I really was just looking for a simple explanation (like shrinkage) and to see if there was a simple solution (without things like building a chamber.) As an accommodation, I have created a 3mf file. It's the same settings (230c) and the same model, but possibly placed differently because it is a recreated 3mf, not the one from when I printed. You are welcome to take a look. But, again, I have moved on.

And, gain, I genuinely appreciate the suggestions that it is possibly shrinkage (which I didn't realize PETG suffered from), and to check for good lamination (which is good enough I cannot break or mallet the object into pieces) and that otherwise the answer is liable to be more complicated.

Thanks.

RE: PETG Print crackling after being printed, shrinking, cracking. Solution?

The Prusament PETG profile uses 240-250C. Your gcode indicates you are printing Prusament at 230C. You made an earlier post in which you had mixed the two up, so this is a reasonable question. A 20C low temperature can definitely affect PETG inter-layer adhesion. If you would provide your zipped 3MF, we wouldn't have to guess as much.

I wonder if this isn't another case of @Bobstro confusing the Prusa i3 Prusament PETG setting with the Prusa i3 MMU2S Prusament PETG setting. (I couldn't resist mirroring your prior snarky comment, sorry) We've had this conversation already. You would be entirely correct if you weren't wrong.

That is why the 3MF is important. It contains all of that information rather than having to guess based on the fragmentary information you provided above. Until today, you had not mentioned MMU in this thread. Makes it awful hard to suggest anything when you only provide fragmentary information. At least describe your tape dispenser accurately.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: PETG Print crackling after being printed, shrinking, cracking. Solution?

@bobstro

Bob, the OP has already posted "I'm honestly not all that interested in solving this problem at this point." so why waste your time?