PETG issue

I am using the Prusa PET profile in Prusa Slic3r.

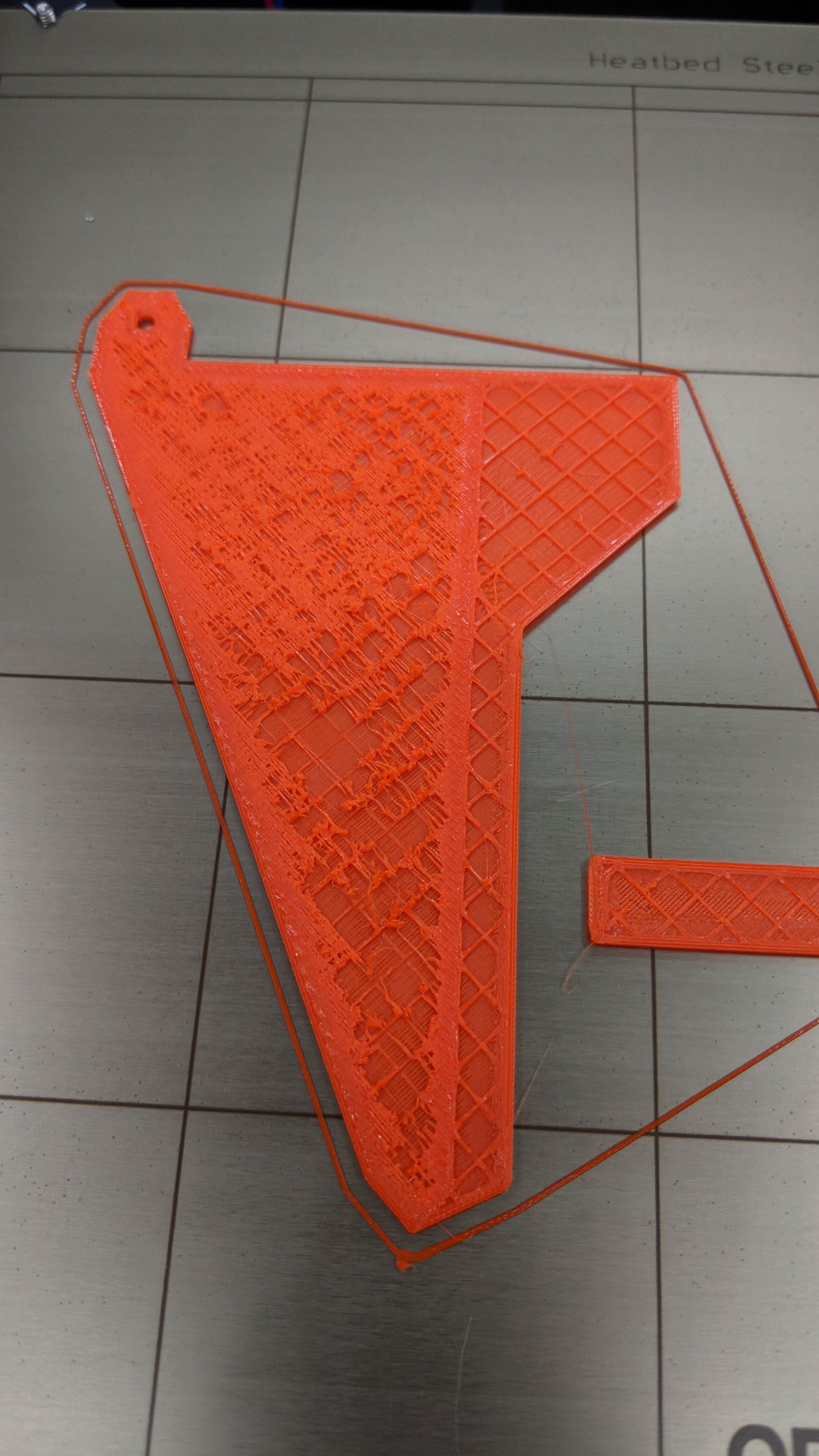

Is this underextrusion or is it simply going too fast? The first layer went down cleanly. You can see another part being printed that is not having the same difficulty, but it is not as wide.

Should I just try printing slower?

Re: PETG issue

I use honeycomb infill since the PETG builds up on the nozzle when it prints “through” a line already put down. There may be another solution, but I have not found it. My prints went from looking like yours, to looking perfect. Maybe someone knows a better answer and will share it.

Re: PETG issue

What speed settings are you using? I've already printed a couple things with the optimal preset on slicer and they turned out fine but I'm getting a lot of feedback on reddit saying that I'm printing WAAAAAAY to fast for PETG. I lowered the default from 200mm/s down to 175mm/s for infill and it had no effect. I'll probably slow it down to 100 and see if that helps along with changing the infill to honeycomb.

Re: PETG issue

I do petg 50mm/s 🙂

---

Gert

Re: PETG issue

Good lord then I must have been super lucky to get what I did at 200mm/s 😯

Re: PETG issue

What speed settings are you using? I've already printed a couple things with the optimal preset on slicer and they turned out fine but I'm getting a lot of feedback on reddit saying that I'm printing WAAAAAAY to fast for PETG. I lowered the default from 200mm/s down to 175mm/s for infill and it had no effect. I'll probably slow it down to 100 and see if that helps along with changing the infill to honeycomb.

I have the speed at the default Prusa PET profile. Little to no stringing and prints are real good when I use honeycomb.

Re: PETG issue

to my unqualified eye it looks like you are having a "Catching" issue. I think the correct amount of PETG is being extruded but it's catching on some of the structure.

Is it adhered to the bed well? Could you be having some sections that are lifting up and letting the piece make contact with the nozzle?

Re: PETG issue

to my unqualified eye it looks like you are having a "Catching" issue. I think the correct amount of PETG is being extruded but it's catching on some of the structure.

Is it adhered to the bed well? Could you be having some sections that are lifting up and letting the piece make contact with the nozzle?

Its definitely not lifting off the bed. Just the infill looks like crap and subsequently the layers on top of the infill look like crap. I didn't notice the volumetric speed override on the prusa PET profile so I'm not sure how much of an effect me changing to default printer settings will have. I think if I just change the infill to honeycomb it will resolve the issue as I have successfully printed with the default settings in PET before.

Re: PETG issue

[/quote]

Its definitely not lifting off the bed. Just the infill looks like crap and subsequently the layers on top of the infill look like crap. I didn't notice the volumetric speed override on the prusa PET profile so I'm not sure how much of an effect me changing to default printer settings will have. I think if I just change the infill to honeycomb it will resolve the issue as I have successfully printed with the default settings in PET before.

[/quote]

If you don’t mind, post the results of what you find either good or bad.

Re: PETG issue

Will do, I've got it printing now with honeycomb as the infill and its not 100% perfect but its definitely printing without lowering down the speed. I'll add some pictures when its done.

EDIT: and now its air printing... 😡 I'll work on this tomorrow

Re: PETG issue

Wow, a bunch of activity on this thread. I had forgotten about it as it had no responses the first few days. In the end, I had to slow down my infill setting to 60 mm/sec and was able to get pretty good prints even with the grid infill pattern. I also lowered the nozzle temp to 230 and most of the stringing disappeared as well.

While doing various testing, mostly with the batman stl, I found I could do solid infill layers fairly reliably at 100 mm/sec. It was just the grid that failed horribly.

I will have to give the honeycomb pattern a try and see if that allows me to print faster.

I was using Atomic Filament Deep Black Opaque PETG PRO, but that spool is about to run out. I have ordered some eSun to try next.

Re: PETG issue

The faster you print, the faster the extruder has to push filament through the hot end to keep up.

Duh, right?

What people forget is, the hot end is dumping heat out one end in the form of molten plastic and introducing a cooling effect to the melt zone in the form of fresh filament on the other end.

The melt zone in the hot end is never the temperature it shows on your machine. It is always cooler in that small region due the the above reasons. To compensate, you must run your hotend 5 to 20 degrees hotter depending on print speed and nozzle diameter. That number printed on the side your roll of filament is just a recommendation and not a cold hard fact.

I've printed every roll of PETG 10 to 15 degrees hotter than its advertised temp with phenomenal results.

To reduce stringing with PETG:

Increase retraction (.7 - .9mm)

reduce z-lift (< 0.3mm)

increase travel speed (150 - 200mm/s)

Hope this is helpful.

Re: PETG issue

The faster you print, the faster the extruder has to push filament through the hot end to keep up.

Duh, right?

What people forget is, the hot end is dumping heat out one end in the form of molten plastic and introducing a cooling effect to the melt zone in the form of fresh filament on the other end.

The melt zone in the hot end is never the temperature it shows on your machine. It is always cooler in that small region due the the above reasons. To compensate, you must run your hotend 5 to 20 degrees hotter depending on print speed and nozzle diameter. That number printed on the side your roll of filament is just a recommendation and not a cold hard fact.

I've printed every roll of PETG 10 to 15 degrees hotter than its advertised temp with phenomenal results.

To reduce stringing with PETG:

Increase retraction (.7 - .9mm)

reduce z-lift (< 0.3mm)

increase travel speed (150 - 200mm/s)

Hope this is helpful.

Thank you for the detailed response. I have two questions:

1) As an example, the Atomic filament shows a range of 230 - 245. Are you suggesting that I print 10 to 15 degrees higher than the lower end or the higher end?

2) To clarify, using the hotter temps allowed you to print at the high infill speeds that the Prusa profiles default to of 200 mm/sec?

I will experiment more once I have a new spool.

Re: PETG issue

sorry for the late response. I too use atomic PETG and print it at 260 with no issues.