PETG: I Give Up!

I have great luck with PLA and Zero luck with PETG. I've tried so many variables with PETG that it would be difficult to list them all. I have tried the standard Prusament settings, several online settings for PETG and made so many adjustments that its driving me crazy. I've had issues with bridging (I know thats common), stringing, blobs, brittle prints, ugly finish etc... I have a Prusa MK2S printer and using Overture PETG (Which had good reviews from what i found). Any help would be appreciated.

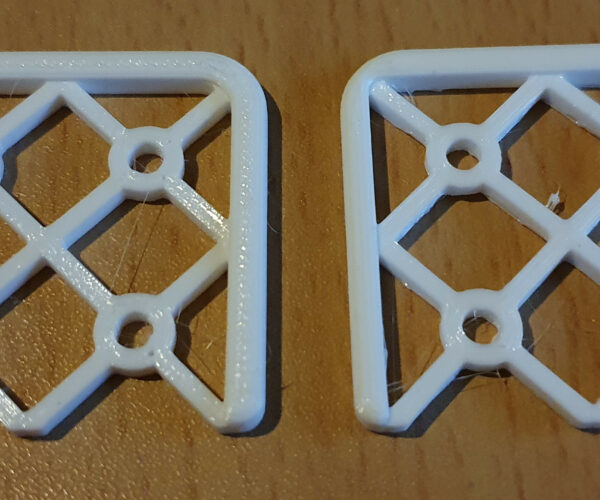

PETG on Left and PLA on Right. I intentionally broke the PETG (Wasn't hard) to show the separation/poor bonding.

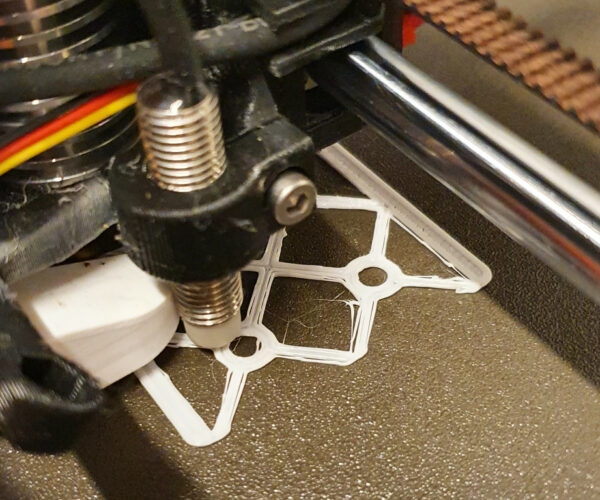

Closer pic of the PETG

RE: PETG: I Give Up!

Forgot to mention that I did "Bake" my filament in the electric oven at 150F for about 4 hours. No change.

RE: PETG: I Give Up!

[...] I've had issues with bridging (I know thats common)

Bridging with PETG is tough. You can experiment with more cooling (Filament Settings->Cooling->Fan settings->Bridges fan speed).

stringing, blobs,

Stringing and blobs may be due to a bit of over-extrusion. You might try adjusting Filament Settings->Filament->Filament->Extrusion Multiplier back 1-2% and see if that helps. Also try adjusting the filament overrides for retraction.

brittle prints,

Brittle PETG is usually an indication of excessive cooling or insufficient heat. Check your cooling settings. I keep PETG at 30-50% if I use any at all. I usually only cool PETG with overhangs. Try bumping temps 5-10C and see if that helps with adhesion. Also, be sure your layer heights are below 80% of your nozzle size to avoid poor inter-layer adhesion.

I can get very durable PETG prints. Here's a typical test result:

ugly finish etc... I have a Prusa MK2S printer and using Overture PETG (Which had good reviews from what i found). Any help would be appreciated.

I've had pretty good luck with Overture. In general, try slowing down until results improve, then bump speeds up gradually.

If you want to save a 3MF project file with your part & settings and attach it to a reply here we can take a look at your settings and possibly have other suggestions.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: PETG: I Give Up!

I've had good luck with Overture, Paramount, Hatchbox and Prusament PETg. For non-Prusament, I've had the best luck using the generic PETg in Prusaslicer and I've copied most of that over to Cura.

The only issue is that yes, it is a bit more stringy and oozy. The strings I get can usually be wiped away with the finger, but sometimes the heat gun is handy.

For PETg I'm very careful to brush off the nozzle area right before starting each nontrivial print. PETg seems to ooze more and that can cause those 'boogers' of scorched filament which will drop off at the most inopportune time and spoil the print. A few quick swipes with a soft brass brush seems to take care of them.

RE: PETG: I Give Up!

You really should persevere, PETG is far superior to PLA. Hopefully the new PrusaSlicer avoid crossing perimeters algorithm will help with the stringing, but anyway a quick hot gun blast usually sorts that. I use Prusa filaments almost exclusively, quality is great, price is not excessive and they don't gouge you for shipping (obviously not an option in you live across the pond).

RE: PETG: I Give Up!

I nearly exclusively print in PETG and you should get better prints.

The only issues I have, printing PETG, is stringing and ooze. Stringing is easily fixed with a hot air blower after the print and ooze can de reduced with the right retraction setting and Avoid crossing perimeter (much better in latest beta).

Following @bobstro suggestions should bring you at the right track.

Have a look at my models on Printables.com 😉

RE: PETG: I Give Up!

Keep trying. I use this stuff for nose cones that go supersonic. You will get there.

--------------------

Chuck H

3D Printer Review Blog

RE: PETG: I Give Up!

OK,

Well I think I have part of my problem figured out, not solved, just know what the problem may be (Partially anyways). I did some first layer square prints on the 4 corners and center of my bed and noticed that my bed appears to be off level. I noticed that some of the squares were squished and some barely made contact with the bed. which in turn I believe caused rippling affects when printing the pics above.

I tried the bed mesh leveling through the calibration and it is not showing any corrections or making adjustments at all to level my bed as far as I can tell. I'm just now getting into figuring out why my bed won't level. The only thing I've done differently in the past month is I did update my firmware from PRUSA (I took a few year break from printing). My PLA prints still turn out good, even on the unlevel bed, but the PETG does not like the bed unlevel.

Could the firmware update have caused an issue since I am using an older printer MK2S? I used the MK2S firmware, but I seem to recall that I still see MK3 stated in places on my screen? I need to dig into the bed leveling a little more to solve this, hope I can figure it out. I plan on buying the newest MK3, but wanted to wait till I at least got this one working again, the lead time for delivery appears to be close to 2 months.

RE: PETG: I Give Up!

There was a thread posted a while ago about a guy using a known-close-to-perfect straightedge and some springs to do a very precise straightening of the plate. If you do some searching you can probably find it.

RE: PETG: I Give Up!

The "nyloc mod" is used to level the Mk3 bed when it is skewed beyond what automatic mesh bed leveling can correct for. I believe the Mk2 is similar, but do verify. There are many guides and YouTube videos on the topic. Here's one that popped up. That doesn't explain why this only recently became a problem. I wouldn't expect a firmware upgrade to matter. That said, this is one of those things that can't hurt to do. I would inspect the bed to see if there's anything mechanically wrong before starting.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: PETG: I Give Up!

PETG Challenge for anyone up to it.

I got my bed leveled, first layer is good now. Still have brittle print for portions of it only. You can see from the pic that when I bend it, the print cracks along print lines. I made a small model of the above pics, the print takes about 25 minutes to print. I have attached my setup files, gcode and prusa slicer file for anyone bored that wants to take a look and/or try to print this and see if you get the same results as me (see pic below)

I tried hitting the "Add Media" button on this reply to attach gcode, slicer and setting files but it said these types of files are not allowed. How do I post these files to my post. Sorry for the nube question(s)

RE: PETG: I Give Up!

@doug-5

Hi Doug,

Try Zipping the file and inserting again please.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: PETG: I Give Up!

Hope that worked? The above is a zip file containing the PrusaSlicer file, G-Code and ini settings file. Hope it uploaded right.

RE: PETG: I Give Up!

I tried to print this from the .3mf file... and i reslicedit didn't look good,

then I remembered that I have a 0.6mm nozzle fitted... Oooops!

so I resliced for the larger nozzle, and it printed strong but a bit stringy...

So I am planning to re slice for the larger nozzle and try again...

which profile did you use? I am guessing one pf the Pretty PETG or similar, because you have two stage warm up on the Nozzle

when you reload a .3mf file, the slicer uses a project related name for the settings, which is not very helpful.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: PETG: I Give Up!

@joantabb

I used the Pretty PETG profile that I got online, but i did make some changes from the original, temps, infill etc to try and fine tune for my printer. The ini file I attached should be what i sliced and printed from. I'm not experienced enough to know how to write the gcode relative to the 2 stage warm up, I just used the settings from the Pretty file.

I'm guessing the .6 nozzle may make a difference in the quality vs a .4 nozzle that I'm using? I'm still making adjustments to my setup to get the test print I attached so it won't break and still zero luck. I'm about at the end of my journey with PETG, UGH!

RE: PETG: I Give Up!

here are the models I printed

the right hand one was with your settings, the left hand one was default Mk3S printer (0.6mm N0zzel version) with Generic PETG Profile first layer 225C remaining layers 235C (these were slightly lower than default, because the first print was stringing And I used 0.2mm layer height...

the second print came out much nicer than the first.

the filament was the end of a roll of 'Real Filaments' Transparent Blue PETG that I have probably had for 2 or three years. no deumidifying or special treatment...

I have re sliced the STL using the Mk3S 0.4mm nozzle settings and attached it blow

regards Joan Test Latice_0.2mm_PETG_MK3S_22m

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: PETG: I Give Up!

I gave it a try too.

The left one was with the defautl PrusaSlicer settings for Generic PETG (0.2 quality profile, 0.4 nozzle)

I used the the only non Prusament PETG that I have at the moment. Real filament PETG.

This print came out just fine with only very light stringing. And it stay together when I bend it. I’m sure I can break it, but I will have to use plenty of force that will break any print this thick.

The right one was with your .3mf file. The first layer looked bad during printing.

I think the bed temp is to low for this PETG and my textured bed.

Normally I have the bed at 85-90 deg C for PETG. Your files has it at just 70 deg C.

The print with your settings finished fine but was hardly stuck to the bed.

It bends a little easier, but doesn’t break.

The first picture is of the top side of both prints. The second is of the bottom side. And the third is of the first layers during the print. There you can see that that doesn’t look great and looks like a weak start.

RE: PETG: I Give Up!

Took me a while to get PETG dialed in, but it's almost all I use now. At first it was a lot of tweaking the filament / printer settings with various filaments. To keep things easy, assuming you have PLA printing fine, get yourself some Prusament. I used all the default settings and the only change I made was to raise the Z offset and PETG doesn't like the nozzle as close to the bed - you can do this either in Slicer Printer Settings (Z offset) or just the live adjust Z. I did the latter since PETG is all I print.

After you do the basic calibration, then try some of the more enhanced ones, calibration cat etc. Any stringing should be cosmetic and depending on what the object it I use a heat gun or even a butane lighter.

RE: PETG: I Give Up!

Well here's an update on my progress if anyone is curious. I had a thought to try a different brand of filament. Went to MicroCenter and got some Inland PETG and all is well now, prints look great. I did make some setting changes so I don't want to bash Overture filament just yet. I intend to go back to my Overture filament and try it with the same settings. No brittleness, great layer adhesion good finish quality. I little stringy, but not terrible.

RE: PETG: I Give Up!

@doug-5

Excellent news, it can get frustrating when nothing works...

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK