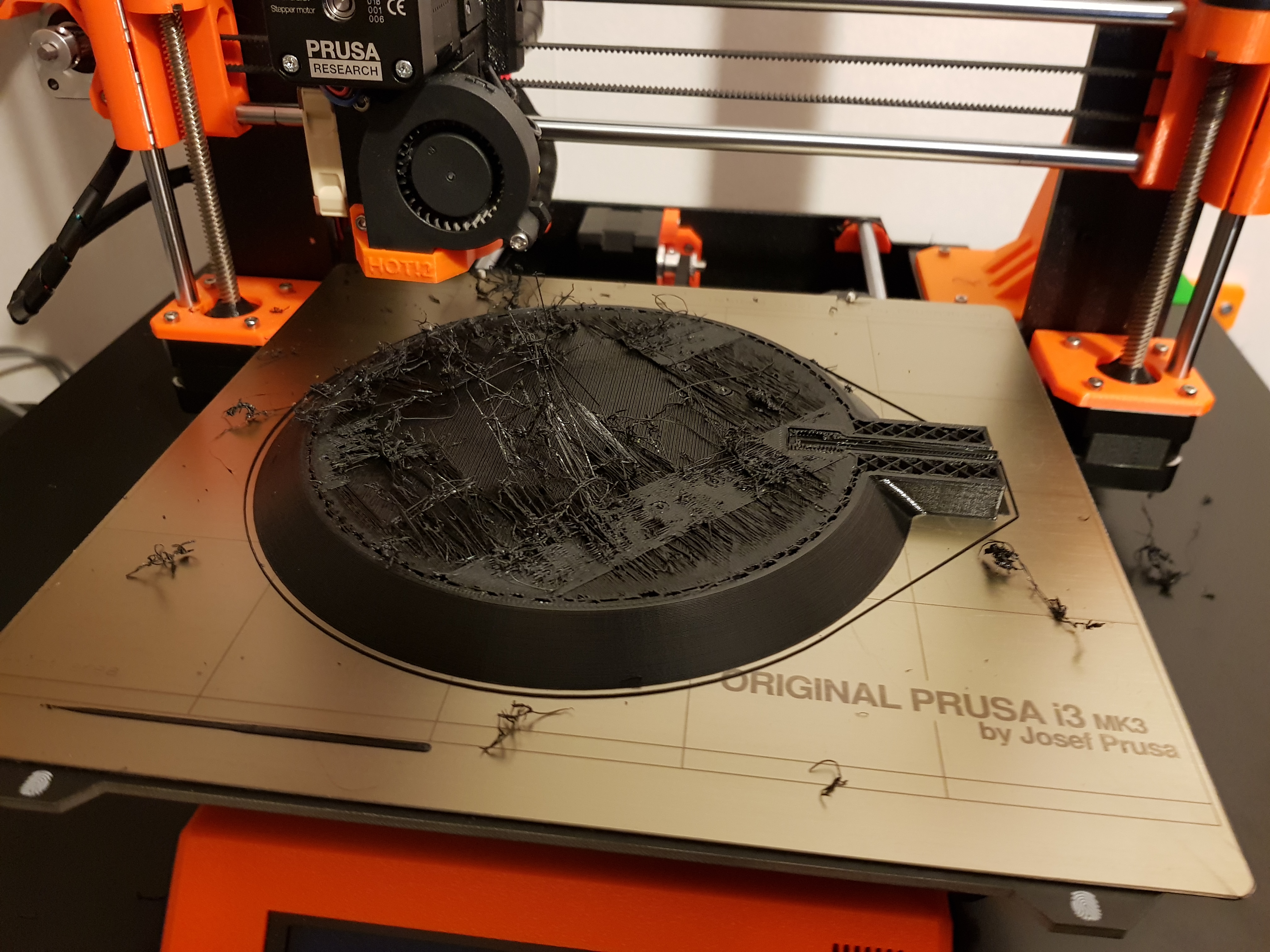

Petg first layer after supports

Hello,

I am printing a custom designed mounting thing for a ubiquiti camera. The middle part of this is a 10mm cutout which is filled with supports. The first layer after the supports didn't stick to the supports and caused a lot of noice so I canceled the print since it would not turn out ok anyway.

I think I will redesign the part so that I screw the bottom ring onto the top part so I can print both parts flat to the bed.

But anyway what settings should I tweak to get rid of this behaviour perhaps raise the temperature? Petg seems harder to print than pla but this part is for outdoor use so I cant use pla for this.

The temperature was standard prusa petg which is first layer 230 bed 85, the rest of the layers 240 bed 90. Filament was prusa petg.

Thanks in advance

Magnus

Re: Petg first layer after supports

You can try lowering the Contact Z distance in print settings to 0.1(what I use) or raise the Interface pattern spacing to make the top of the supports smoother and easier to stick the next layer onto.

Both settings are found in Print Settings tab> Support material of Slic3r PE

Anything can be made better

https://www.myminifactory.com/users/Joe%20Prints

Re: Petg first layer after supports

Thanks.

Will try that.

RE: Petg first layer after supports

Currently I’m having same issues with petg did you resolve the problem ?

RE: Petg first layer after supports

I do a lot of petg printing with supports. I've found that petg with a ton of supports prints WAY better hotter, like 250 or 255. it has less tendency to to drag the supports, which are by default thinner extrusions.

RE: Petg first layer after supports

Thanks @ssill2 , I have increased the nozzle to the 255 from 240 (Contact z was already 0.1), lets see if this is going to work better or not. I'm very happy with overall print but it is really noisy first level after supports as the original post sender already mentioned.

RE: Petg first layer after supports

I came to the realization a month or two ago that the 230/240 default for prusament PETG really didn't work well at all for supports. It seems like the less viscosity of the hotter filament really keeps the support extrusions from getting dragged as the nozzle moves. I'll be interested to see if you have similar experience.

RE: Petg first layer after supports

You can try lowering the Contact Z distance in print settings to 0.1(what I use) or raise the Interface pattern spacing to make the top of the supports smoother and easier to stick the next layer onto.

Both settings are found in Print Settings tab> Support material of Slic3r PE