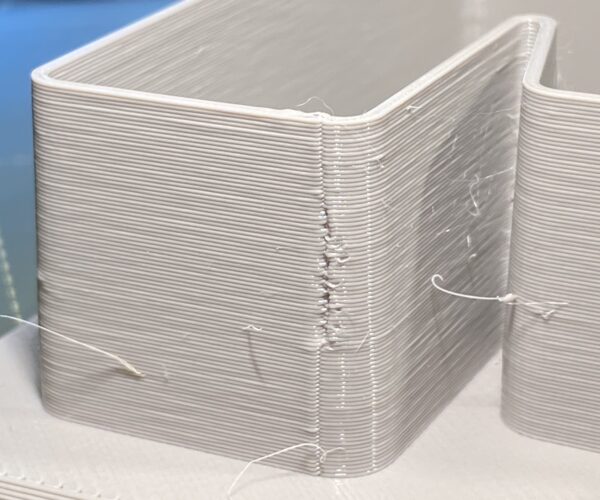

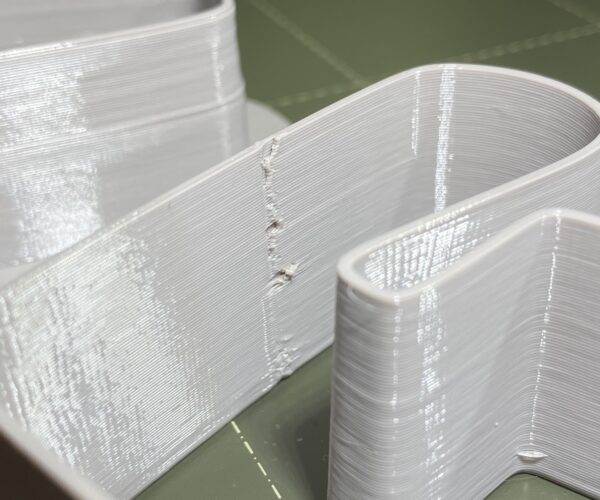

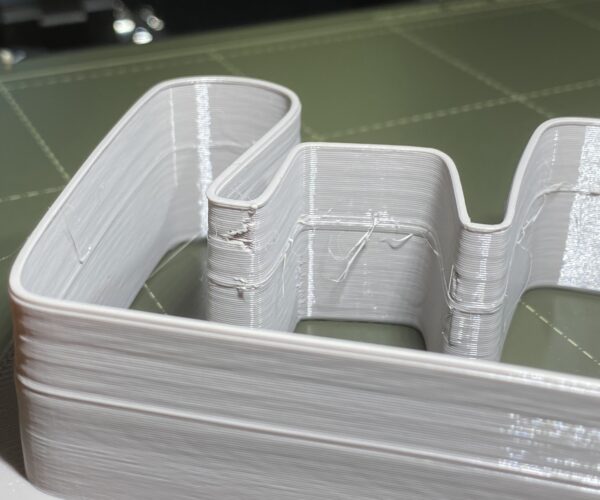

Perimeter Gaps With PETG

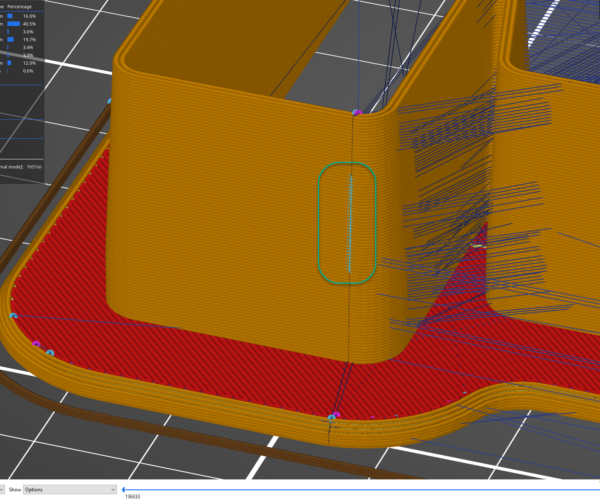

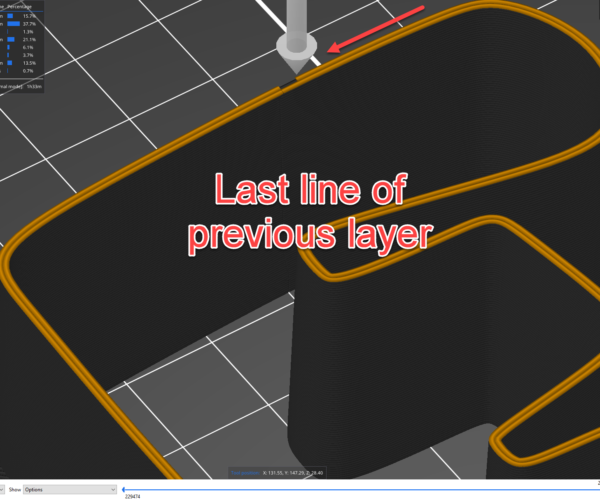

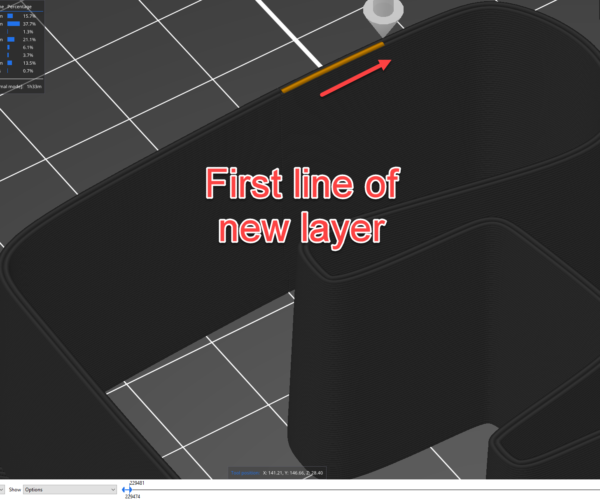

Making some cookie cutters and getting some holes in perimeters. The thickness of the walls gradually neck down to two extrusion widths wide at the cutting edge. From what I can tell, the first line of the current layer is directly next to the last line of the previous layer and perhaps there is some retraction issue or delay causing the PETG to not extrude for the first fraction of a second on the new line??

.3mf

Save Project ("File", "Save Project As") as 3mf

ZIP 3mf-file

Upload zipped 3mf-file ("Choose file" under edit window)

Prusa i3 MK3S+ FW 3.11.0 (kit dec -20), PrusaSlicer 2.6.1+win64, Fusion 360, Windows 10

Possible solution

This file is sliced in Super Slicer but I don't think anything is unique to that slicer over PrusaSlicer. A complete retraction calibration test from 0-1.5mm showed no change but disabling "wipe while retracting" seems to have fixed the issue. I suspect that something about the wipe or the time for the wipe seems to have pulled the filament back enough that there wasn't enough present for the start of the new line. With the wipe disabled, the retraction still occurs, but its very very fast and the print just keeps going.

You might find some useful information in this post.

you may want to look into turning off "Detect thin walls" and adjusting "Extrusion widths"

Also Ringarn67 is very qualified to help with this if you let him. it's a good idea to post your Zipped up .3mf project file exported from Prusa Slicer. you might be happy with the results, even supersized.

Regards

Swiss_Cheese

The Filament Whisperer

Seam.

Normal Z seam (zits). Walls too thin plus infill issues with too few perimeters. It is possible to make tapered walls, but it takes expertise.

More tuning...

Normal Z seam (zits). Walls too thin plus infill issues with too few perimeters. It is possible to make tapered walls, but it takes expertise.

Walls are tapered as-is. The final wall thickness necks down to 1.2mm and I'm using a 0.6mm nozzle. As you can see from the images, the issues are present when there are only two external perimeters (the thinnest portion) and where the part is much thicker near the base. After disabling "wipe while retracting" and reducing retraction length from 1.4mm to 0.8mm, results are better, but still not perfect. Examining the gcode shows the issue occurs when a "deretraction" takes place.

Perhaps the nature of (my) PETG leads to a delay in extrusion response? Spitballing here, but if the PETG is delayed in response, both the retraction and deretraction could be slightly off, leading to the material not being ready at the end of the extruder for a new line? This could explain the benefits of getting rid of the wipe while retracting and reducing the retraction length.

Sure looks like you have a really bad model

Some models are hopeless.