Over extrusion Help Needed

MK3S+

Prusament PETG sliced with Prusa’s suggested settings

Textured sheet

Total Print Time: 7 days 10 hours

Firmware Version: 3.11.0-4955

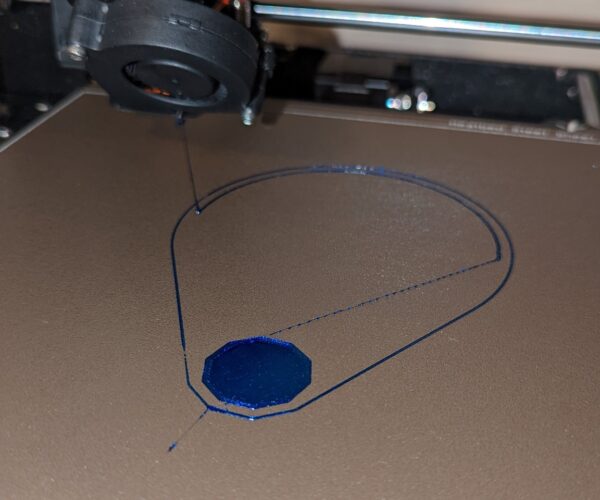

Problem / Observations – looks like over-extruding after the first layer with excess filament getting pulled across the print. There also appears to be more filament laid down on the test strip than normal.

Background: This is our third Prusa (newest of two MK3S+) that we use to support our small side business. It’s about two weeks old at this point and has worked flawlessly until now. We print the same models on all three printers and have had minimal issues. This one has me stumped though. We started a new part the morning after a successful 9 hour print. This new print failed after a few layers due to what looks to me like over-extrusion. We checked several things and did a few test prints, all of which failed in the same manner. Some of them as soon as the first layer.

Troubleshooting steps taken:

- Thoroughly cleaned the bed with IPA. Bed adhesion is not a problem.

- Redid the first layer calibration using this tool off Printables: https://www.printables.com/model/163547-first-layer-calibration. Our Z offset was a little close to the bed. We ended up backing it off .010. This change did not help our problem – although we didn’t think it would either

- The only hardware change on this printer is a silicone sock. I’ve had it on there since the very first print (and the other printers) without issue.

- We ran the PID calibration at 250c just be sure this isn’t a problem.Did a nozzle fan speed check mid print – it’s where is should be, ~4150 if I remember correctly.

- The hot end fan on this printer has always been significantly quieter than our other MK3S+. You can feel air getting pushed over the hot end when you put your hand on the right hand side of the extruder, so I don’t believe the fan is an issue.

- We swapped filament just to make sure we didn’t have a wet roll.

Wondering if anyone has any other suggestions of relatively easy checks before I dive into the extruder looking for clogs and ground up filament. We haven’t changed or adjusted any hardware on this printer, or tweaked slicer settings from the Prusament presets. Thanks!

RE: Over extrusion Help Needed

Worn nozzle was the culprit for this one. Not sure how as we have printed exclusively in PETG since new.

RE: Over extrusion Help Needed

It happens. Glad you found the problem quickly and it was a relatively easy fix.

For what it’s worth, when I changed the worn nozzle on my MK3S+ I switched to the E3D nickel plated copper nozzle. I print primarily PETG and find this nozzle to be somewhat less prone to filament sticking to it than the stock brass nozzle, while retaining the same temperature profile.

Cheers