Objects are not sticky enough to the another object

Hi.

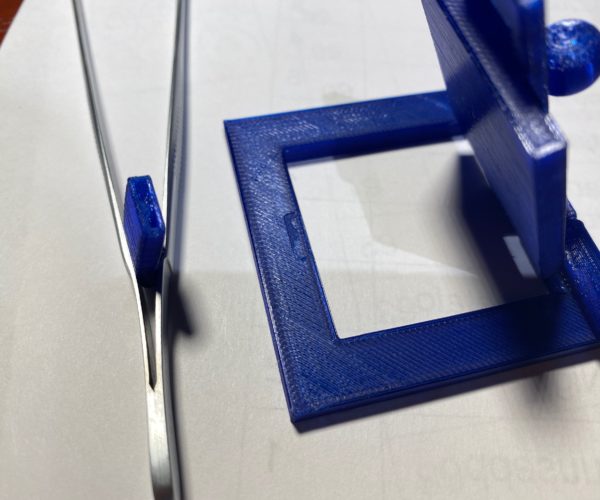

I am a rookie in 3d printing and i have serious issues with objects that not sticky with layers. Is there any solution to make the connection stronger? I am printing with MK3S-MMU2S and original Prusa PETG. In the picture you see after pringing the small piece is broke off.

RE: Objects are not sticky enough to the another object

Set your vertical shell perimeter to maybe 5 to increase wall thickness.

Same for horizontal shell layers. I pretty much always use 5.

Higher infill percentage is stronger too. Just uses more filament.

RE: Objects are not sticky enough to the another object

Weak interlayer adhesion is usually a sign of not printing hot enough, especially with PETG. Print a series of thinnish tall towers at different temperatures and with different fan speed % and test to see what works for your filament.

RE: Objects are not sticky enough to the another object

@neophyl

So far no problems with temp, but maybe i must try to smaller prints with higher temp. Thx for the advise.

RE: Objects are not sticky enough to the another object

Hotter, slower and more extrusion width.

Maybe less fan:

RE: Objects are not sticky enough to the another object

Long video - but interesting. Thanks for linking!

RE: Objects are not sticky enough to the another object

This area has a tricky geometry. The soft, low infill piece meets the very stiff base plate. (Plus the base plate will be cold when the next layer is printed.)

If you cannot redesign (round) this area you could use a modifier block in your slicer to set the infill for the lower part of the piece to 100%. This has worked for me several times when the arms of snap-on parts broke.

All in all this is a very "2D" design that is not optimized for 3D printing.