Mk3s+ PETG warping / large-ish print

Hi guys,

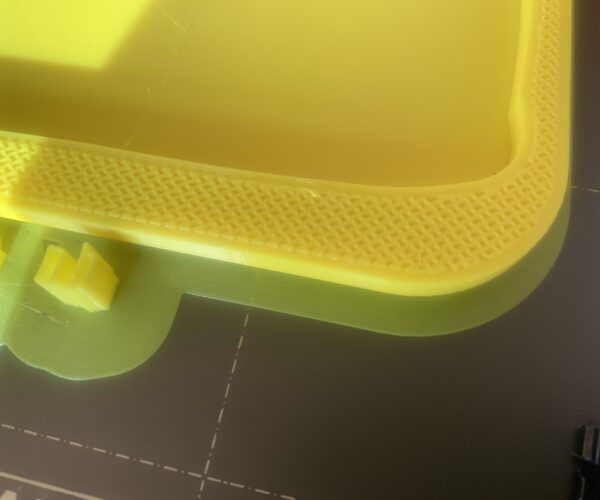

I know that this is nothing new (as I've read through quite a few threads on this forum); case in point I'm trying to print a new multimeter case from PETG, and warping is giving me a headache 🙁

I've setup an external and internal brim to better hold it in place and I've dialed in the PETG I'm using to eliminate stringing/oozing; everything is setup and ready to rock'n'roll. but it still lifts the brim after a short while into the print (total time at approx. 2days).

I have seen many people print bigger things like planters and the like from PETG (for water tightness I assume) with no deformation at the base due to warping and so I imagine I'm doing something wrong.

Any experience/solutions would be more than welcome.

Currently using "Premium PETG" from 3DFILLIES ( https://3dfillies.com/petg-filament-175mm-1kg/)

Settings:

- 247°C nozzle temp

- 80°C Build plate temp

- 0.2mm layer height

Thanks in advance :3

RE: Mk3s+ PETG warping / large-ish print

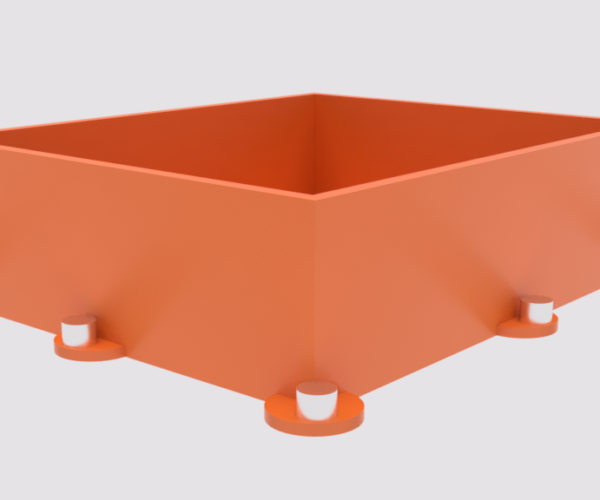

Why dpo you don't print the box upside down ?

RE: Mk3s+ PETG warping / large-ish print

@knickohr

My first thought too.

@popepanator

I print a lot of large models with PETG, and if a brim is not working, I tend to add a thin layer of Layerneer Bed Weld. Plus, I've seen a lot less warping since switching from the Prusa to the BCZAMD textured sheet.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Mk3s+ PETG warping / large-ish print

@knickohr

yes I agree, it should be printed flipped. However that still going to likely have issues with warping. I've printed things slightly larger than that and the only real way to prevent warping is to break up those long runs of filament.

RE: Mk3s+ PETG warping / large-ish print

@fuchsr

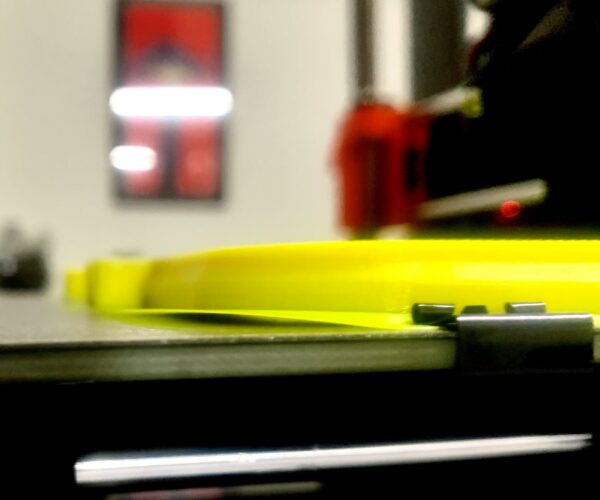

Even with the layerneer I've seen the corners of the sheet be pulled up 🙂 I think Tim on here suggested using binder clips on the corners of the sheet to prevent this.

Take a look at this post, I post pictures of a similar part. The corners of the steel sheet are pulled right up.

I ended up redesigning my part.

RE: Mk3s+ PETG warping / large-ish print

@ssill2

Wow, I've seen plenty of warping but not the sheet actually pulled up. Nice 😉

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Mk3s+ PETG warping / large-ish print

You might control it a bit by using a tall skirt and increasing the bed temperature.

Cheerio,

RE: Mk3s+ PETG warping / large-ish print

@fuchsr

I've had that issue too with a large rectangular part for my cr10 rebuild to use linear rails. It kept lifting the sheet off the magnets. My solution was the same as Tim's, used binder clips at the front and back. Made sure they wouldn't hit anything or get in the way on the print but it was the only way to get it to work.

And it was in an enclosure too lol.

RE: Mk3s+ PETG warping / large-ish print

I guess to put a positive spin on it, you sure didn't have any lack-of-adhesion issues... 😀

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Mk3s+ PETG warping / large-ish print

@ssill2

Interesting... Unfortunately, I do need it to be watertight so as to prevent ingress of condensation or oil from ruining the meter, however I may add some internal wall cavities to alleviate the lateral tension as you did with that drawer insert. I should probably use the smooth PEI sheet as well to get better bed adhesion, as unlike your drawer mine is just coming away from the build plate.... :/

What do you think, should I maybe lessen the part cooling to reduce the immediate effects of the upper layers pulling on the lower ones (cooling over time)? or have it cool quicker (aka 100% fan speed) to "set the line" there and then?

@Knickohr

The very first time I tried to print this (though that was several attempts ago) I printed it right-way-up (Thinking it was the intuitive way to go as there is less filament wastage and better bed adhesion) though it failed at about 2hr into the print due to warping/lifting from the bed.

@fuchsr

Interesting, I was unaware about aftermarket textured sheets. I'll try the smooth PEI for now but will look into this in the future as (I'm thinking of a self-watering planter for my sister's birthday later in the year) 🙂

Once I'm finished with uni assignment work for the week I will get back on the horse and start working at this print once more. itching to try some of these suggestions.

One last thing; has anyone downloaded the latest firmware update for the mk3? worth it? (haven't had the chance yet once again due to uni work), reading through the release notes there was something about retraction gcode.

RE: Mk3s+ PETG warping / large-ish print

Also, sorry about the late reply. It would seem I'm halfway around the world, compared to you guys.

RE: Mk3s+ PETG warping / large-ish print

@popepanator

It’s the nature of the beast. Those long runs just want to contract. Next time I might try the binder clip thing. I realize it’s not always possible to redesign the part.

RE: Mk3s+ PETG warping / large-ish print

@ ssill2

If only someone would invent a suction heat-bed. Like an air hockey table but in reverse with tiny little pores in a fine grid pattern to forcibly suck the part down to the build plate XD

RE: Mk3s+ PETG warping / large-ish print

Saw a picture on Reddit, they put magnets on "ears" a few mm in print, depending on height of ears + thickness of magnets. Pretty obvious

Can't find the picture but it looked something like this

Haven't tried it myself, so don't thank me if it works. And, more important, don't blame me if it ain't lol

Put the magnets in the same direction as the heatbed magnets

Prusa i3 MK3S+ FW 3.11.0 (kit dec -20), PrusaSlicer 2.6.1+win64, Fusion 360, Windows 10

RE: Mk3s+ PETG warping / large-ish print

@ringarn67

Now that is clever. Although with a box like shape such as the OP has you wouldn't need the ears, you could just put them in the bottom after its printed to give extra adhesion.

RE: Mk3s+ PETG warping / large-ish print

@neophyl

+1. That *IS* clever. Will add that to my toolbox of "anti-warp" methods!

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Mk3s+ PETG warping / large-ish print

@Ringarn67

That is very clever, Might have to get myself some neodymium magnets in the near future!

RE: Mk3s+ PETG warping / large-ish print

@popepanator

adhesion isn't really the problem lol if it curls the corners up with layerneer applied the only way to avoid it is something holding the corners down stronger than magnets lol

RE: Mk3s+ PETG warping / large-ish print

Okie dokie,

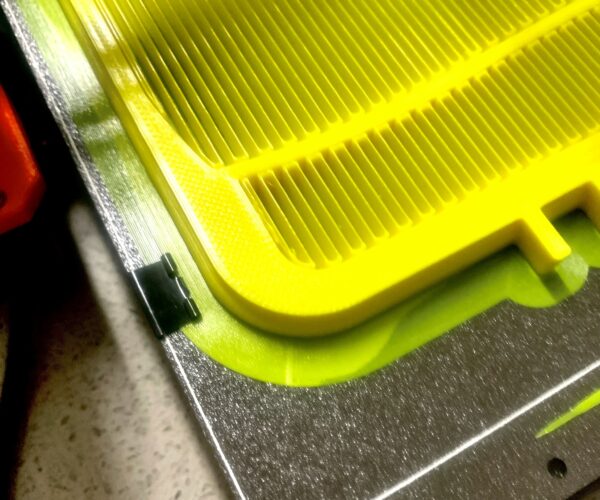

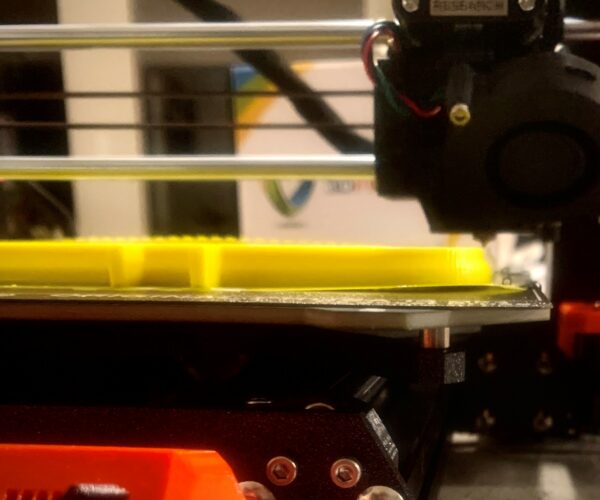

I’ve spent the best part of today super duper fine tuning the first layer to be absolutely perfectly applied using the smooth PEI sheet (to eliminate my average adhesion).

Spent a long time correcting the bed mesh level (turns out I had a low/concave center that I was unaware of) to as perfect as possible.

I’ve restarted the main print noting the advice offered here and have re-orientated the part right way up.

I’m going to bed now and will hopefully wake to find very minimal/no warping