RE: Massive Warping with PLA

Is there room on the build plate for a brim or mouse ears on the corners?

Could also try glue stick. I know everyone on here says it shouldn't be necessary, but in a pinch it does help.

Is the printer in an enclosure? PLA doesn't need to be, but just having something to block any stray breeze can make a difference.

RE: Massive Warping with PLA

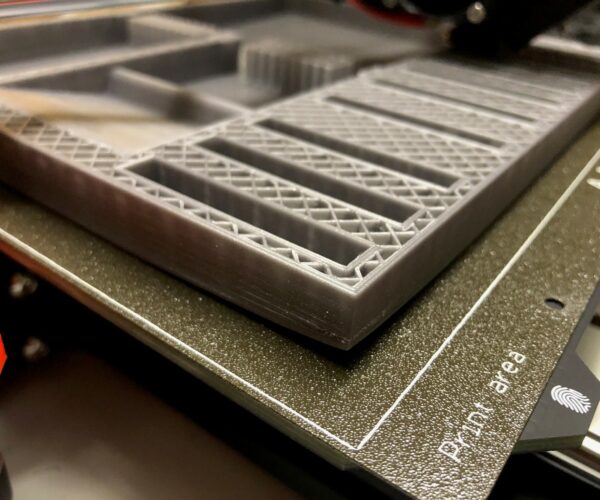

Could reducing % or changing the infill pattern help ?.

RE: Massive Warping with PLA

Wash bed with dish soap to get maximum sticking.(very important)

Check your first layer, if it is a little to high, it will not stick very good.(very important)

A big brim attach to the model.

Extra: if needed.

Glue stick.(check if your glue stick works, some do not work good).

First layer more heat. To get more sticking.

No wind on the printer.

Print a little hotter all layers.

Try different filament, check for water in filament.

RE: Massive Warping with PLA

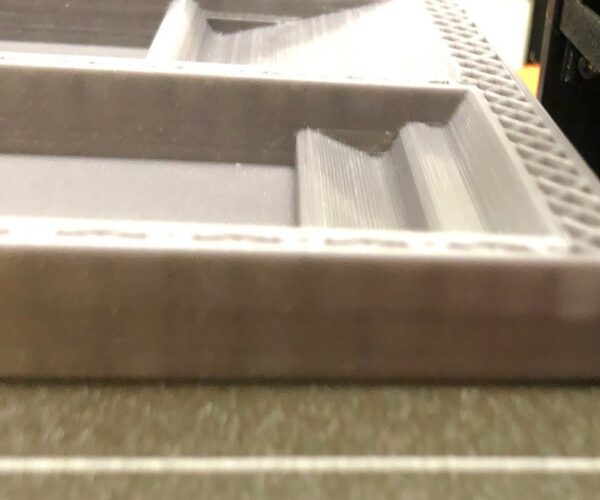

It's a common problem with large prints that have sharp corners. If you access to the design files, add fillets to the corners. If not, @darcshdow and @peter-m26 had good suggestions. In my hands, adding a brim works most of the time, plus glue stick if needed.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Massive Warping with PLA

Switch to a smooth PEI build sheet for PLA.

Avoids all the adhesion problems with the textured sheet.

RE: Massive Warping with PLA

I met same problem, did you fix it yet?

RE: Massive Warping with PLA

I also agree with the advice on the print bed. The structured build plate doesn't have all that great adhesion with PLA. The smooth one is much better in this regard.

If with good cleaning and smooth bed adhesion issues persist it can also help to recalibrate the first layer. With such great prints and sharp corners this might not be enough, in which case you have two options, try brims and/or use adhesive like magigoo or something.

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE: Massive Warping with PLA

I had similar warping problems on my MK3S+, and I found four methods to get it to stick again that worked for me:

- Cleaning the bed with some IPA

- Increase the first layer extrusion width to about 180% of the nozzle diameter

- Raising the bed temperature about 5C

- Doing a Live Adjust Z and setting it to very close to the bed (most slicers including PrusaSlicer have built-in elephants-foot compensation)

Usually for me I need to do just the first one, but sometimes I had to try multiple to get it to stick. Hope this helps!

RE: Massive Warping with PLA

I've found that Layerneer really helps on adhesion with PLA prints on the textured build plate.

Usually a dab at where each corner will be will do the trick.