Loading PP filement issue

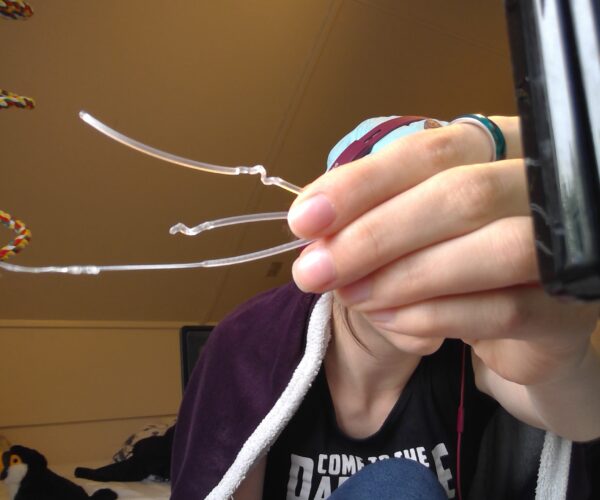

I wanted to try out printing PP filement. I wanted to load it and at first it seemed to be going fine. But after about 10 maybe 15 seconds the filement stopped moving. It turned out it had build up withing the parts that move the filment down (sorry not sure what they are called, but it's those things that circle around and push it down). I ended up having to do a coldpull and tried again. But with this attempt the same problem was there. See picture for how the filement looked after pulling out (Didn't think of taking a picture while it was still stuck ^^; )

I then tried using normal PLA filement and that worked fine, so I think it really has something to do with the PP. I was using the preheat option for PP on the 3D printer.

Does anybody else have this problem/know how to solve it? Thank you in advance!

RE: Loading PP filement issue

Information?

Temperature of extruder?

Temperature of the PP filament, on the box?

If the extruder is not hot enough, it can not push through the nozzle, the filament can bent in the extruder gears, this can also happen if the speed is to fast.

Check the springs settings, see prusa manual.

RE: Loading PP filement issue

https://all3dp.com/2/3d-printing-polypropylene-how-to-3d-print-with-pp/

If PP is a softer filament, then it is possible that the spring should be a little looser.

Keep in mind that if extruder is not hot enough, it will get stuck, play with temperture, make a temp tower.

Use google on how to print this material.

RE: Loading PP filement issue

I'm wondering what you did to fix it? I tried printing today first time with PP (Fiberology) and had the same issue. The filament had gotten all entangled in the gears and I had to clean it out - so I'm weary now.

I used magigoo PP glue on the bed. The temps was as in the pic - the default settings from slicer for this filament:

If it gets stuck in the gears, does it still mean the springs are too tight? Because the gears are *after* the springs. I guess I'll try loosening it on my next try - it's not clear to me how I know how tight it should be.