Lines and bulges in printed object

Hi,

a few weeks ago i bought this 3D printable RC Boat as a Corona downtime project and i am since struggeling with printing it: https://www.cgtrader.com/3d-print-models/hobby-diy/other/kwikjet-the-3d-printable-jet-boat

My first problem was a starter of a fluorescent lamp on the same phase causing power surges which lead sometimes to X-Axis Layer shifts without the detection of a crash in normal mode and crash detection on. (Reproducably when switching on and off this lamp). Now the printer is on a different power line (phase) and at least the layer shifts are gone.

But i still have bulges and lines which seem to be related to this https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-hardware-firmware-and-software-help/witness-lines-in-print-prusa-slicer/ and this topic https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-how-do-i-print-this-printing-help/buldge-when-print-reaches-solid-layers/

My Setup:

MK3S+ with MMU2S

PrusaSlicer 2.3.0

Cura 4.8.0

Simplify3D 4.1.2

Verbatim PETG

20% infill and 10mm brim

These lines and bulges always happen at the same position so they are hardcoded into the gcode.

I did lots and lots of testing with cleaning, checking belts, motors, connectors, lubricating the rails and whatnot and missprinted a lot of filament in this process until i realized, it must be in the gcode.

After previewing the gcode in Prusa, Simplify3D and Cura i could not find anything usefull. BUT finally i uploaded the gcode file to www.gcode.ws and the errors are visible in the 3D preview. It is not that easy to spot them. I had to play around with zoom and viewing angles but.... they are visible.

So i thought: PrusaSlicer is to blame.

Installed Cura and tried again. Same problem but it seems to me at slightly different locations. Then i bought Simplify3D (at least for the 2 weeks test periode), same problem. At least in the gcode.ws. I never tried to print them.

Since just the rear hull part of this model seems useless to me without the middle and front section i uploaded the .stl from the rear section.

I am working since almost 4 weeks on printing the hull part searching for a really strong sticking first layer setting for warping reduction, then finding the mysteriously apperaing layer shifts in X-Axis which took ages to track it down to the fluorescent lamps in the basement rulling out belt and rail issues, controler issues, motor issues, temperature (overheating) issues and whatnot.

The now remaining issues i have tried to overcome by cleaning the nozzle, cleaning the rails, detaching and reataching the belts, calibrating the printer again and again, changing the nozzle, using prusament filament, cold pulls....

I'm new to the 3D printing world. My printer is only 2 months old. I wasn't expecting a hassle free plug and play experience and have no problem with fiddling arround but my experience so far is 3D printing is to unterlieable, expensive (missprinted 7 Spools of Verbatim PETG and 1 Spool of Prusament worth 190,- €) and just frustrating. I am really close to giving it all up.

I know, this helps no one. I did not think such a (in my eyes) simple print will be so hard to takle. I don't want to print a perfect benchy... just an avarage ok'ish print.

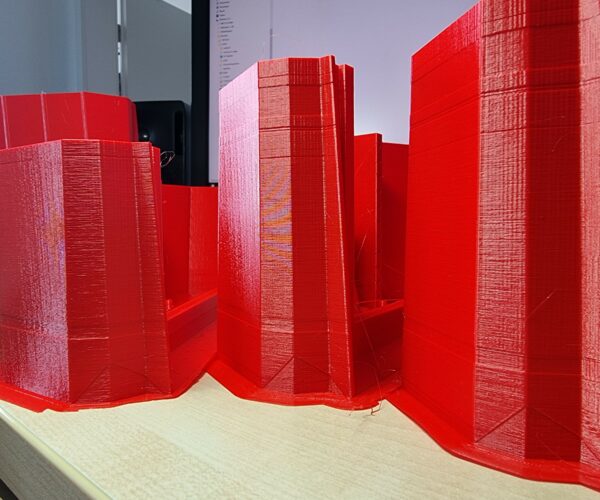

I attached some pictures from the prints. They are aborted and dont represent the whole stl file and gcode.

I know there are many settings in the Slicer which can be played around with. But i don't want to missprint another 7 Spools to get, hopefully, to a point which is an acceptable outcome. I'm not after "perfect" im am just after "OK".

Hopefully someone has an idea what to do or could point me in the right direction. I don't know what to do.

Thank you for reading this whole depressing thing. =)

hull - 1.4mm thickness - rear_0.2mm_PETG_MK3SMMU2S_1d3h8m gcode New Prusa Slicer Project and exported gcode from rear hull section hull - 1.4mm thickness - rear stl

RE: Lines and bulges in printed object

Increase the wall thickness.

RE: Lines and bulges in printed object

@dan-rogers

Thank you Dan! I am starting the print right now.

Sadly i still can see a small line and a kind of "border" in gcode.ws. Hopefully it is only something visible in gcode, not in the real print. I will post the outcome. The possible errors i see in gcode.ws should be printed in about 8 to 10 hours.

RE: Lines and bulges in printed object

If you can see it in preview you will almost certainly see it in an actual print.

RE: Lines and bulges in printed object

@neophyl

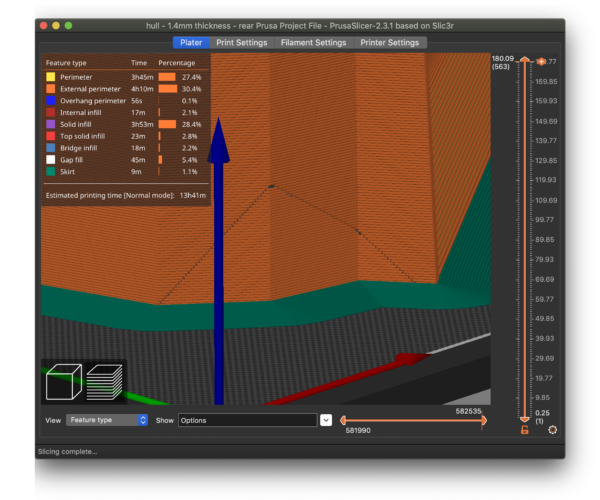

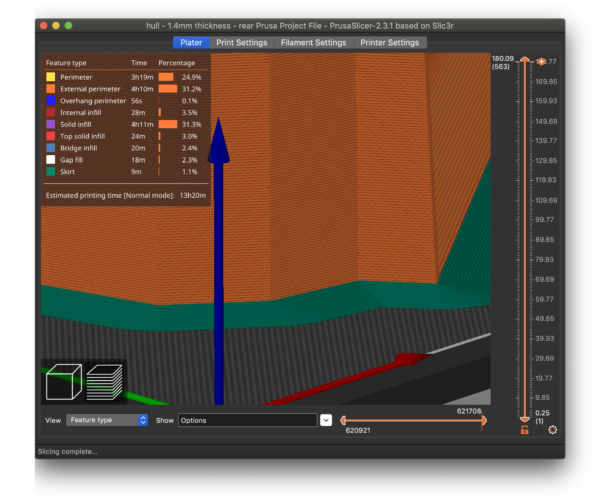

Thanks neophyl. Honestly i am expecting to see those errors in the finished print too. But Dan's recommendation is so simple and straightforward that I just hope it works anyway. At least it looks way better in gcode than the first version. Instead of many lines and borders there are just the first two left. And they changed in apperance.

RE: Lines and bulges in printed object

- This is questionable 3D print design. 1.4mm is just too thin for reliable printing with a 0.4mm nozzle. It's probably *just* possible to manage with very careful settings but this should not be included in a published part without a clear warning.

If you can, increase the thickness to 2.4mm. If not, try requesting the change from the designer.

Otherwise try a smaller nozzle but this is going to take a long time to print.

Re: the lamps; An electrician should be able to reduce the problem, it may be impacting other equipment around the house.

Cheerio,

RE: Lines and bulges in printed object

@andyrandy

Do zoom in on the print in slicer preview - if you see defects, the defects are probably built into the model you purchased.

RE: Lines and bulges in printed object

@dan-rogers

Hi Dan,

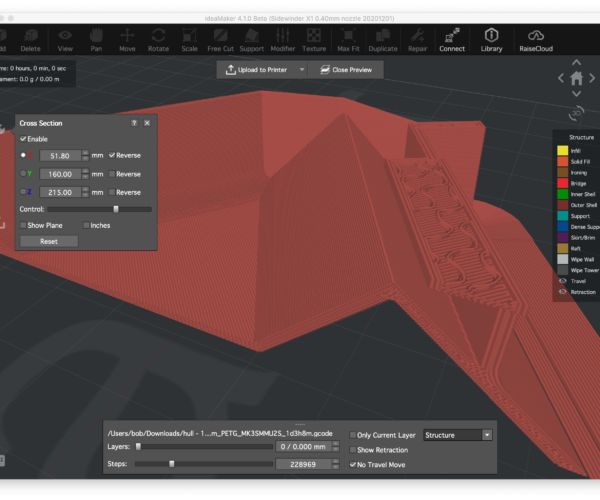

in the PrusaSlicer Preview for gcode there are absolutely no defects visible. The same goes for IdeaMaker. They are only slightly visible if i open the gcode in Cura. But the generall visualisation from gcode not generated in Cura is quite bad/weird. A more or less good visualisation is from gcode.ws. But in my opinion they are only visible because of the way the toolpaths are visualized. If you look close enough, you can't see any defects. But at a certain distance with some wired preview aliasing going on, they are quite visible and represent the defects on the actual print in location and size.

I believe the stl is fine because a lot of people printed it without problems. But almost all of the feedback is from creality users, i haven't seen a print from a prusa.

And whats more, the defects change. If i make a new projekt, rotate it a bit, the defects are at a different position and have a different width and are a few more or less.

I have to rotate the stl slightly on the printbed because i need a bit of space around the object for a brim for the mid and the front section. They have very little footprint and tend to warp with PETG.

That was the reason it took me so long to realize it is something in the gcode. Because after almost every misprint i tried to fiddle around with the Slicer to find a solution. And every time i did something to the model in the slicer before printing a new version, different defect pattern emerged and i assumed a problem with the printer itself.

If i just save the PrusaSlicer Project, open it again and generate a new gcode without changing anything, the same pattern is vissible in the gcode. If i change it a bit, like just a tiny rotation, the pattern is different.

RE: Lines and bulges in printed object

@diem

Hi diem,

thanks for your thought on this matter. As i have written to Dan the model is quite popular and has many good reviews. But they are mostly from creality users. I haven't found a picture of a print made with a prusa.

It might be thin, yes. But in those places of the print where the defects do not occur, the print quality looks flawless to me. And the defects are at the same position if i print the same gcode again. The apearance of the defects seem kind of random to me. I mean they do not seem related to certain parts or objects within the model. And if i change the rotation of the part a bit in the Slicer an make a new gcode file i get a different defect pattern. So i assume the STL files are ok, the printer is ok... it has something to do with the Slicer... no idea.

I only live as a tenant in this house. So i strongly believe the owner won't do much about that.

Small power surges are quite common. If you plug soemthing in with a transformer, like a brick from a notebook, you might have seen and heard a small spark. That is the same what is going on in the starter of a fluorescent lamp. Only in those old startes this small spark is used to start the fluorescent tube but can also backfire in the powerline. Like if you plug in the power brick from a laptop.

And every PSU which delivers power to delicate electronis should be able to catch those surges. And because they happen quite often during the day (for example pluging and unpluging from devices with transformers) every decent PSU has a circut which can catch those surges (Power Surge Protection) so they don't affect sensitive electronics.

But i found the problem and a different power outlet which is not connected to other devices. So at least this is solved for me.

RE: Lines and bulges in printed object

some new thoughts here . I looked at the gcode in the viewer - and did not see the defects there. What's interesting is that the defect bands seem to track to internal features that change the amount of infill on a layer or end at the same heights as the bands.

Some things to check - if you have the PETG printed belt tension gauge - how are your belts? Try and get them to mid range if you can. That could help.

Also, read the threads here on effects of going from infill to no infill - there are some slicer induced issues - no slicer is perfect - but there are strategies you can use if the bulge is a factor.

Also, read the articles on prusa's blog for different types of defects - there is some evidence of shadowing (usually can dial that out).

RE: Lines and bulges in printed object

I didn't read everything posted here so maybe this has already been suggested, try this, it should look good in your slicer and print fine.

I tried to match the specs you posted as close as possible. hull - 1.4mm thickness - rear_Swiss.3mf

Good Luck

Swiss_Cheese

The Filament Whisperer

RE: Lines and bulges in printed object

@andyrandy

It might be thin, yes. But in those places of the print where the defects do not occur, the print quality looks flawless to me. And the defects are at the same position if i print the same gcode again. The apearance of the defects seem kind of random to me. I mean they do not seem related to certain parts or objects within the model.

It's possible for a thin-wall defect to be related to the position/angle of the print on the bed; the point at which the nearest printable position crosses from one line of 'pixels' to the next. Look up antialiasing if this old 2D screen/printing reference is new to you, modern kit is high enough resolution for the issue to have been resolved for almost all uses.

Your 0.4mm nozzle has a default extrusion with of 0.45mm. The two exterior faces fill a total of 0.9mm, leaving 0.5mm to fill. 0.45mm doesn't quite reach and there isn't room for two extrusions even with reduced extrusion...

...so to join the two exterior faces the print dithers between 3 strands and too thin; and four strands and too thick.

You need more perimeters, at least two for a smooth wall and three for an accurate one. If the wall is less than about 2.25mm thick a 0.4mm nozzle doesn't have enough room to align the outer perimeters correctly and still keep it connected to the other side, the slicer has to make compromises.

And every PSU which delivers power to delicate electronis should be able to catch those surges.

It's not just surges but also spark noise, hf spikes that can interfere with digital signals; often propagating wirelessly. Filters are available.

Cheerio,

RE: Lines and bulges in printed object

It would be helpful to see all the settings you're using. Save your current 3MF project file, zip it up, and attach it to a reply here so we can see your part & settings and give better recommendations.

If your concern is the uneven vertical surfaces, I agree that the vertical wall inconsistency is likely the "buldge" effect. Unfortunately, no single fix has been identified that will work in all cases, but a few things that help:

-

Be sure you're not just seeing the effect of minor warping/lifting/curling along edges or in corners. This can really throw troubleshooting off. Rotate the print and verify the problem occurs in the same place. You're using a large brim, so presumably, bed adhesion is holding throughout.

-

Slow down external perimeter speeds (and all speeds in general). If the nozzle is moving a bit too fast, you get slight under extrusion on some layers. These are apparent as adjacent layers print with slightly different extrusion rates. You're using 25mm/s for external perimeters which is usually sufficient for consistent flow.

-

Calibrate your extrusion multiplier for each filament. Any slight over or under extrusion can produce very small but noticeable variations in layers with different features (e.g. infill, gap fill, top solid infill). The closer your slicer settings match your actual printer and filament, the more accurate the gcode will be. I notice you've got your extrusion multiplier set to 1. Have you done a calibration for that filament?

-

Calibrate linear advance (LA) for each filament. LA adjusts the flow of filament to compensate for acceleration and deceleration. If it's not right, you may see artifacts even away from features such as bumps or hole on the same layer. In some cases, a hole on one wall causes imperfections on the far side of the print. You seem to be using the Prusa PLA profile with a LA factor of 0.08. Are you using Prusa PLA?

-

Add an external perimeter if vertical walls allow it. The thicker combined perimeter allows the filament flow to even out.

-

Tweak perimeter extrusion widths. The problem can appear when the slicer switches between gap fill, sparse infill, and solid or top infill. If you can find a multiple of perimeter widths that minimizes these transitions, it can work for a specific print. You've sliced with 2 0.45mm perimeters. You might try adjusting these up or down.

-

If you are the part designer, make vertical free-standing walls thicker. IME, at 1.5mm thick, the problem is less noticeable. Looking at this STL, the vertical walls shouldn't be a problem with a 0.4mm nozzle. You can try for an even multiple of extrusion widths, although be aware the PrusaSlicer does some internal calculations for overlap between extrusions that can throw you off.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Lines and bulges in printed object

@bobstro

He did, I've already uploaded an adjusted version

The Filament Whisperer

RE: Lines and bulges in printed object

He did, I've already uploaded an adjusted version

I'm only seeing rear_0.2mm_PETG_MK3SMMU2S_1d3h8m.zip from OP and that's a 1 day print.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Lines and bulges in printed object

@bobstro

For reference sake, these are all the files the OP posted.

hull - 1.4mm thickness - rear_0.2mm_PETG_MK3SMMU2S_1d3h8m gcode

New Prusa Slicer Project and exported gcode from rear hull section

hull - 1.4mm thickness - rear stl

they did bleed together a bit.

I have issues with the way the forum is setup all the time as well, sometimes I can see it sometimes I can't

Sometimes I get notified of responses, most of the time I don't.

and I still cant get on prusaprinters, just saying

BTW I was not meaning to sound brash, if I did.

The Filament Whisperer

RE: Lines and bulges in printed object

One quick observation:

This defect appears to match the bottom of your pictures:

Can be cleared up by disabling Print Settings->Layers and perimeters->Quality->Detect thin walls:

Detect thin walls tries to make the print "more accurate" by extruding lines thinner than normal (or recommended for strength). Letting it print with less exact extrusion widths often clears up these sorts of "tears". It might be worth seeing if that clears up some of the other issues as well.

The gcode indicates that feature is off, but the appearance sure matches the slicer preview. Is the uploaded 3MF identical to what generated those prints?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Lines and bulges in printed object

bobstro you are correct, the adjustment I made to the OP's .3mf was an extrusion width, it has corrected the problem no thin wall detection.

I'm 32% of the way through printing the OP an example to show.

The Filament Whisperer

RE: Lines and bulges in printed object

In this case the OP was using default settings the model is very very well made and needs no alteration, there is no bulge or reason to contact the maker. it was as simple as changing two numbers in slicer, the outer shell prints solid and without blemishes. I was going to post all this with the example but I fear it may be lost to the OP by the time the print finishes which is 6hours and 45 min from now.

the corrections are reflected in the .3mf I posted, as well as an improved model orientation.

anyway Ive got to get back to work,

Good Luck

Swiss_Cheese

The Filament Whisperer

RE: Lines and bulges in printed object

@bobstro

Thank you for all your suggestions. Sorry it is so difficult to spot those files i uploaded. There is also a video showing what is going on in gcode.ws https://forum.prusa3d.com/wp-content/uploads/2021/04/hull-rear-section.mp4

It seems there should/could be a option to intergarte it into a videoplayer window which didn't work. Sorry.

I know those prints are not perfect (aside from the obvious defects) but i am only two months into this matter and i am slowly learing context of all those options and how they reflect on the finished print.

Right now i am pleased with the print results but i want to understand more about this matter and get better results along the way.

The whole model prints very well in generall with a slightly modified Verbatim PETG preset from Prusa to get better bed adhesion.

@Swiss_Cheese

Are you really printing this hugh thing right now??? I am blown away! But you don't have to do that. This print is extremely time consuming and expensive. Don't get me wrong, this is so kind of you. But i want to print it, so i should at least do the pinting myself and not occupy someones printer and use their filament. So please be so kind to PM me your Paypal adress so i can do something about it. Otherwise i will feel really bad.

Right now i am not at home and will get back on Friday. So it will take a while until i can start your modified version on my printer.

Could you please tell me which magic numbers you changed to what to get a flawless print and the reason you changed it? And how do i get a improved model orientation? What do i have to consider? It would be awesome if i could use this knowledge for the other hull parts and all my further prints?

And maybe someone is running into the same problem and could benefit from your experience.