Light weight PLA prints with internal structure and curved edges

I've been messing around with this material for quite a while and I've gotten close to getting what I would consider good prints, but I am just shy of hitting the mark. I haven't been able to resolve these two problems:

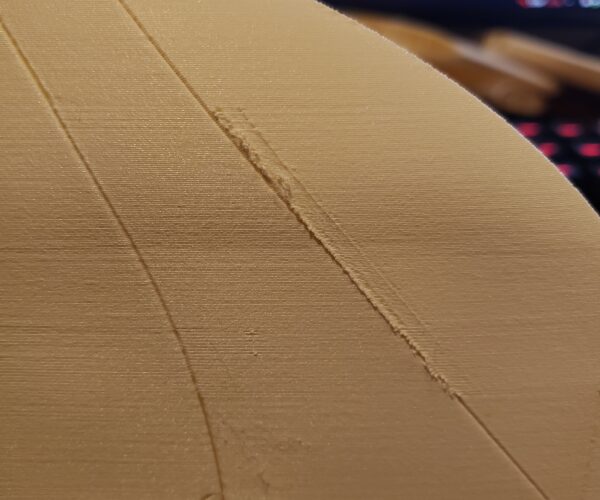

1) On excess curved surfaces the material appears stringy rather than a full and flat surface

2) The internal supports (embedded in the project file) appear stringy before the join and have "boogers" where the walls meet

Ive tried adjusting temperatures at certain layer heights for problem number 1. My current print is going from 180 and increasing up to 200 (to get some additional LW-PLA to close the gap) as it gets closer to the curve that Im having problems with.

I've tried adjusting my retraction to resolve the 2nd problem. I went from 0.8 (default) to 2.0, and back.

Im also trying to change the print orientation on the build plate.

So far, it doesn't look any different.

Any other suggestions? I've attached the 3mf as a zip file.

RE: Light weight PLA prints with internal structure and curved edges

Ive Never printed with this material, however I've got two examples printing in regular PLA , when they are done I'll post the .3mf's for you to consider. The polymaker material your printing states that it can be printed as regular PLA, I've made a strongest and lightest version. I'll post when they are done. The .3mf files will show variations of extrusion width, and layer height as well as a couple other properties.

Regards

Swiss_Cheese

The Filament Whisperer

RE: Light weight PLA prints with internal structure and curved edges

@addohm

I printed this 3 different ways, just to test strength. The first I printed with the default 0.45 external perimeters, this yielded a weak connection of the internal support structures, in other words the overlapping areas of the internal support into the wing surface weren’t adequate in several areas based on the tolerances built into the geometry. As well there were some very obvious areas towards the top where the layers would not overlap with enough contact to be supported by the layers below them (I corrected this before printing the first test). So I had to make a couple changes to the next test to be sure that I wouldn’t encounter the overlapping issues experienced both in the built in support structures, and the overlapping of the layers on the harder curve in the structure towards the top tip of the model.

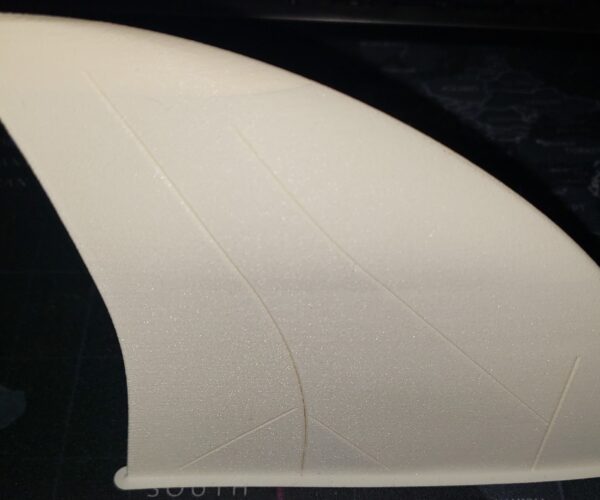

To do this I went immediately to an external perimeter width of 0.6 mm. In this next test I used that perimeter width for the entire print as well as adding a height range modifier for the last 6mm of the print to add material in the form of top layers to prevent the failure of those perimeters. You will also notice layer height adjustments meant to help with the layer overlap on the wing surface towards the top of the model.

My Inexperienced opinion, the 0.6mm is a winner for strength,and wing stability, this yielded a 20.47g wing (with my regular PLA).

In (Wing_section tip_Swiss_06.zip)

But far be it from me to leave well enough alone.

I moved forward wanting, without knowing my ass from a hole in the ground about 3D printed planes, or wings and decided to shoot for as strong and lite as I could get. That said, in my final test I adjusted the extrusion widths for external perimeters. I already learned from my very first print that 0.45 would not get me the structural integrity I needed with the material I was using,(probably the cause of the stringing you were seeing) So I stepped the overall extrusion width up to 0.5mm and graduated this up to 0.6mm as needed by use of Height Range Modifiers, as well as graduating the layer height. I did this to accommodate not only the internal structure but also the unsupported upper areas of the model. Each of these prints aside from the first was a success. I want to reiterate that I have never had cause to print a foaming filament as you specified, however the one you shown specifically mentioned that it can be printed as regular PLA. in my tests I used Overture3D Matte “Grassgreen” PLA the cheapest PLA I could find as I’m not compensated for the prints I help with. However I believe its properties are similar in temperature and extrusion relative to what I have read about the material you report to be using.

The final version printed in 2hours 21 min, and weighs 17 g. It seems reasonably strong.

In (Wing_section tip_Swiss_Variable.zip)

I hope this helps.

Swiss_Cheese

The Filament Whisperer

RE: Light weight PLA prints with internal structure and curved edges

I really appreciate your response. At this point I don't think its necessary to be so modest. 🙂 I'm truely thankful that you've explained your results and, more importantly, why you made the changes. It really helps us all learn.

I will probably try printing this tonight. I'll first just try the 3mf you've shared, then depending on the results modify it for the material difference. I get that they say you can just print it as regular PLA but that hasn't always been my own experience. I'll post both results just so we're both learning 🙂

@addohm

I printed this 3 different ways, just to test strength. The first I printed with the default 0.45 external perimeters, this yielded a weak connection of the internal support structures, in other words the overlapping areas of the internal support into the wing surface weren’t adequate in several areas based on the tolerances built into the geometry. As well there were some very obvious areas towards the top where the layers would not overlap with enough contact to be supported by the layers below them (I corrected this before printing the first test). So I had to make a couple changes to the next test to be sure that I wouldn’t encounter the overlapping issues experienced both in the built in support structures, and the overlapping of the layers on the harder curve in the structure towards the top tip of the model.

To do this I went immediately to an external perimeter width of 0.6 mm. In this next test I used that perimeter width for the entire print as well as adding a height range modifier for the last 6mm of the print to add material in the form of top layers to prevent the failure of those perimeters. You will also notice layer height adjustments meant to help with the layer overlap on the wing surface towards the top of the model.

My Inexperienced opinion, the 0.6mm is a winner for strength,and wing stability, this yielded a 20.47g wing (with my regular PLA).

In (Wing_section tip_Swiss_06.zip)

But far be it from me to leave well enough alone.

I moved forward wanting, without knowing my ass from a hole in the ground about 3D printed planes, or wings and decided to shoot for as strong and lite as I could get. That said, in my final test I adjusted the extrusion widths for external perimeters. I already learned from my very first print that 0.45 would not get me the structural integrity I needed with the material I was using,(probably the cause of the stringing you were seeing) So I stepped the overall extrusion width up to 0.5mm and graduated this up to 0.6mm as needed by use of Height Range Modifiers, as well as graduating the layer height. I did this to accommodate not only the internal structure but also the unsupported upper areas of the model. Each of these prints aside from the first was a success. I want to reiterate that I have never had cause to print a foaming filament as you specified, however the one you shown specifically mentioned that it can be printed as regular PLA. in my tests I used Overture3D Matte “Grassgreen” PLA the cheapest PLA I could find as I’m not compensated for the prints I help with. However I believe its properties are similar in temperature and extrusion relative to what I have read about the material you report to be using.

The final version printed in 2hours 21 min, and weighs 17 g. It seems reasonably strong.

In (Wing_section tip_Swiss_Variable.zip)

I hope this helps.

Swiss_Cheese

RE: Light weight PLA prints with internal structure and curved edges

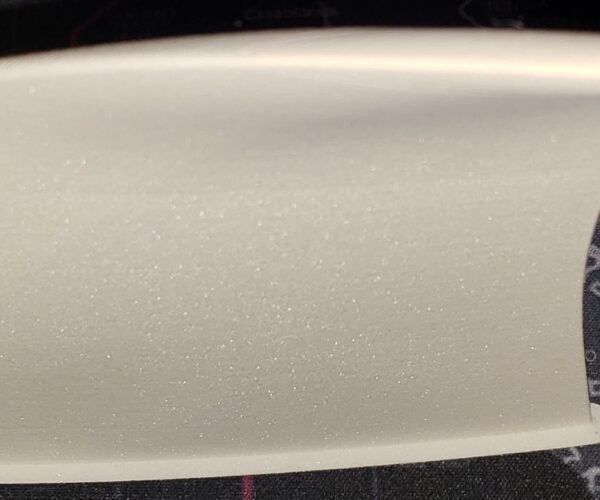

I got some really interesting results and definitely learned a lot through this evolution. The best results I got (so far) were using the `Wing_section tip_Swiss_Variable.zip` file with the filament settings I had already tuned for the LW-PLA. I printed the same file without adjusting the material settings also. There's quite a bit of boogers on both prints but theyre easy enough to clean off and sand down. The original print pictured (I'll call Print 1) was 9.8g untrimmed. The aforementioned file with the tuned filament settings (I'll call Print 2) is 11.46g. The raw file without the filament tuning (I'll call Print 3) is just 11.54g! I expected much more weight because of the significantly higher print temp. Print 1 and 2 look identical with the curved edges being mostly completely filled in on Print 2. Print 3 looks similar to Print 2 except on Print 3 you can see a prominent transition line\ridge where the layer height changes. This is probably because of the higher heat causing more material expansion. It's given me something to work with though and I think I've learned enough to get it closer to perfect.

RE: Light weight PLA prints with internal structure and curved edges

@addohm

Glad you were able to get something out of that. I printed the first wing section you posted about a month ago, I was just curious at the time how strong it would be. Same PLA material, I was surprised by it. Now after having printed this latest part a couple different ways I realize I should have probably used 0.5 extrusion width. It printed without fail at 0.45, but I have to wonder how well it would handle a crash.

Anyway, I’d be interested in seeing how things turn out.

Regards

Swiss_Cheese

The Filament Whisperer

RE: Light weight PLA prints with internal structure and curved edges

Truth be told, I have no hopes for this long term. It will be perfect for rapid iteration but given how fragile it is and how PLA behaves in the elements, specifically the sun, it will only ever be good for prototyping in my opinion. I did print a wing section out to test in PETG and it's just WAY too heavy for what I'm trying to do, which I'd design a solar flyer than can fly as long as the sun is shining with 20m of buffer in the battery.

RE:

I just realized my booger problem.... Octolapse settings. 🙁 Turned off octoprint, boogers gone. Need to change the settings so it doesn't move the print head to take a pic.

RE: Light weight PLA prints with internal structure and curved edges

After about a total of 20 failed prints, I finally got to where I think I needed. I could not have gotten here this quickly without your help @swiss_cheese. I learned a ton!

RE: Light weight PLA prints with internal structure and curved edges

I had fun helping with this, I also learned a few things.

The images of the finished wing tips look great.

The Filament Whisperer

RE: Light weight PLA prints with internal structure and curved edges

Thanks. I am going to try and push it a little further. Right now its 10.25g (all aforementioned weights are without trimming btw). I can definitely get it lower if I want to spend the material. If I can get it under 10 I'll be content 🙂

RE: Light weight PLA prints with internal structure and curved edges

Interesting discussion to follow.

@addohm I hope you are aware that once your plane gets airborne you absolutely have to post something in the "Hall of Fame" section. I'm pretty sure I'm not the only one here who is keen on seeing a bit more about that project.

Good Luck and Success for it!

Hansjoerg

RE: Light weight PLA prints with internal structure and curved edges

Thanks for the little boost 🙂 I've printed everything but with dive season here my time is been diverted. I will certainly updating. Thanks again!

Interesting discussion to follow.

@addohm I hope you are aware that once your plane gets airborne you absolutely have to post something in the "Hall of Fame" section. I'm pretty sure I'm not the only one here who is keen on seeing a bit more about that project.

Good Luck and Success for it!

Hansjoerg

RE: Light weight PLA prints with internal structure and curved edges

@addohm

Where are you that you have a Dive season? I Dive as well, here we dive all year long. I'm in California. Cold water, warm Sun.

The Filament Whisperer

RE: Light weight PLA prints with internal structure and curved edges

@addohm

There is no such thing as a dive season, have you never heard about dry-suits? 😉