Large flat print is warping...

I'm trying to print this, in PLA, but not warped, like it is:

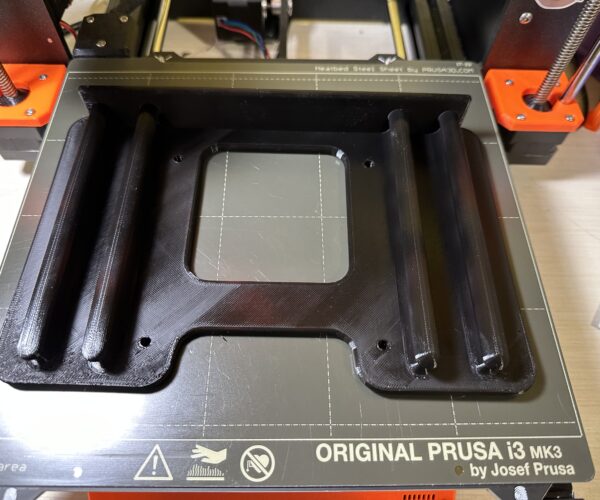

It's a VESA mount to connect to the back of my monitor. The 4 rails are for attaching cases to hold my computer, an SSD, and other items.

The problem is it's warped:

I printed a smaller version previously and it warped a small bit, but I didn't notice it at first because it wasn't as much of a warp and was in a different place and didn't create issues. On this, with the warping on the top/front part of it, the bottom comes off the print bed and then the rail is not tall enough for parts to slide on it.

I recalibrated X, Y, and Z axes, then did a sheet of test prints to recalibrate the Z axis adjustment for distance from the print head to the print bed. I posted about that in another thread, last night, because the sheet of test squares had some inconsistency which gives me concerns about bed warping.

I normally clean the bed with isopropyl alcohol, as per instructions on the Prusa website, but after I did all the recalibrations, I cleaned it with a tiny amount of Dawn and warm water. My printers are in our barn and I was in the house, but watching the print on OctoPrint with a webcam and it didn't look like it was starting to warp until well into this 13 hour print (and, even then, I couldn't tell for sure, with shadows, and it was late at night, so I wasn't about to walk to the barn to check in person).

We do have a humidity issue in this area. This project is part of my overall setup and cleanup that will eventually lead to a much different workspace with venting (also for a CNC system that uses a laser and sets off the smoke alarm) and to storage facilities to protect filament from the excessive humidity that comes from living in a forest near a river. However, there are a lot of things I have to print as part of that process. So if humidity is a primary cause of this, I need a work-around to use for a while.

What can I do to keep this from warping? According to the Prusa website, glue is generally not needed for PLA, but I'm thinking I need that here. If so, I'm open to suggestions on a good glue to use - preferably one I can drive out and buy or something I can get from Amazon in a day or two.

I'm also concerned for more other prints. What is causing this and what do I need to do to deal with it? (And, again, if it's humidity, what kind of temporary measures I can take until I get things set up to deal with the humidity.)

RE: Large flat print is warping...

It's common for large box-shaped/rectangular objects to warp. Assuming Live Z is well calibrated and the steel sheet is clean (using hot water and fragrant-free dish washing soap), here are a few approaches that have worked for me (copied/pasted from previous posts):

- Slow down print speed.

- Add Mickey Mouse ears to the corners. There's a "helper disk" in PrusaSlicer's Add Part library but I prefer to simply add a cylindrical, maybe 10mm diameter, change height to single layer height, then place the part at the corner. Repeat for each corner.

- Add a brim around the model, 5 mm or more. Wider or 2 -layer high brims may be needed but may not work with the size of the model or may require being added in your CAD software.

- Use Layerneer Bed Weld ( https://www.amazon.com/Printer-Adhesive-Layerneer-Original-Filament/dp/B079984GV5/ ). You only need a thin layer.

- If you have design control over your part and it's possible considering the intended use, you can try to round the edges and/or add holes to the base of the model.

- Combination of above. Usually, brim/ears does the job, or some Layerneer if needed, but large, rectangular objects can be a challenge.

- Also, drafts can encourage warping, so printing in an enclosure (with doors open for PLA) may help.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

Buy a washing machine or a freezer and stand the empty box over the printer to act as a temporary enclosure - cold air and drafts are frequent causes of warping.

Cheerio,

RE: Large flat print is warping...

It's common for large box-shaped/rectangular objects to warp.

Good to know it's not just me. Originally I searched for help using different terms and didn't find much. Then I wrote the title to this thread and "warp" just came naturally. After I wrote the post, I thought, "Maybe I should search using that," and found more info.

Slow down print speed.

Is there a range where I should slow it to? I've always used the given print speeds, so I really don't have a baseline for how much to slow it. Is it just the first layer I should slow down? (It takes 13 hours as it is - if I don't have to slow it down for the whole print, that'd be helpful.)

Add Mickey Mouse ears to the corners. There's a "helper disk" in PrusaSlicer's Add Part library but I prefer to simply add a cylindrical, maybe 10mm diameter, change height to single layer height, then place the part at the corner. Repeat for each corner.

Thank you for phrasing it that way. I saw something similar and had no clue what they meant until you used the phrasing, "Add Mickey Mouse ears to the corners." Read that and it clicked. "Oh, I get it!" Above you mention it happens with squares. Is there something about the shape, then, that creates the issue? I have a vent system I'm putting together where I'll have to print my own wall plates for it and if the shape matters, then it'll save me a lot of effort if I change those to circular plates now.

Use Layerneer Bed Weld ( https://www.amazon.com/Printer-Adhesive-Layerneer-Original-Filament/dp/B079984GV5/ ). You only need a thin layer.

I thought, "While I'm waiting for answers and thinking about what to do, maybe I can do some maintenance on my system." I started going through the printer tool drawer and found some glue - with no English on the label and found it came with the Prusa printer, so I'm trying that for now. When you say only a thin layer is needed, that makes me think it's possible whatever force is pulling or pushing up on the outer parts may not be exerting too much force.

If you have design control over your part and it's possible considering the intended use, you can try to round the edges and/or add holes to the base of the model.

That's something I can do with my other parts - and that does seem to make it seem more likely that it's the square shape. For my vent system, I can certainly use a different shape. For this - well, if the glue holds, I'll stick with it, since it's not likely I'll be printing up multiple copies and I don't want to spend a lot more time on it, but I may add the MM ears or something like that to help.

Also, drafts can encourage warping, so printing in an enclosure (with doors open for PLA) may help.

That's part of what I'm working on - it'll double as a vent hood. Why do you suggest open for PLA? (As best I can tell, there are no drafts on the printers. Tried to avoid that with setup.)

I'm ordering some Layerneer now, so I've got that on hand in the future, along with the glue that shipped with my printer.

RE: Large flat print is warping...

may not be exerting too much force

The force can be significant. I print a large brick shaped object regularly, and I need to use paper clips to hold the sheet to the bed or the force of the warping will pull the sheet up against the magnetic pull of the bed.

Is there a range where I should slow it to?

As usual, "it depends". I'd start with 50% (not just the first layer). Having said that, I usually just use Layerneer and brims, which tends to do the job.

Why do you suggest open for PLA?

Closing the doors and the increased internal temperature may lead to print artifacts or, worse, heat creep. I leave the doors open for PLA and PETG and close it for ASA and other high temperature filaments.

13 hour print

Seems like a lot for this model. You're always welcome to post your model here (as a zip-compressed 3mf project file) to see what suggestions the friendly folks here may have for speeding things up. The obvious suspects are infill type and density, perimeters, maximum volumetric speed etc. Often using height modifiers or modifier meshes in specific areas can lead to dramatic improvements. One of the great things about this community is that quite a few folks hang out here who can do great things to optimize a print setup. That large object I mentioned before, collectively we were able to bring the time it takes to print it to a fourth of what it was with default settings.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Large flat print is warping...

The force can be significant. I print a large brick shaped object regularly, and I need to use paper clips to hold the sheet to the bed or the force of the warping will pull the sheet up against the magnetic pull of the bed.

Wow! I have a tendency to not trust any kind of glue but so much, but it must be pretty strong if the glue is holding down a print against something like that.

As usual, "it depends". I'd start with 50% (not just the first layer). Having said that, I usually just use Layerneer and brims, which tends to do the job.

I do my design work in Blender and that allows for text files to be kept in the file. When I open it, it includes the text files I've written. I'm going to note that issue in there and if this attempt works and I have to print it again, I'll use brims and add that to the design. That's also a tip I'm going to remember to use from now on - sounds like a simple and good solution.

Closing the doors and the increased internal temperature may lead to print artifacts or, worse, heat creep. I leave the doors open for PLA and PETG and close it for ASA and other high temperature filaments.

That's good to know! The system I'm working on will vent my printers and my CNC. While I couldn't find vent fans with good programmable speed control, I'm using a Z-Wave switch and I have Home Assistant running automation for my house, so I'll be able to easily create automations for the vent system. For instance I could have the fan turn on for 5 minutes than off for 5 minutes for hours, until a print is done. The table the printers are on is 2'x4' and the hood/cage (I tend to use both terms) will be at least 2 to 2 1/2' high. Most of it will be plexiglass, but I want to do some work so the vent fan pulls odors out (and smoke, from the CNC) without creating draft issues, so I'm still working on a design that will pull air in through some inlet and out through the vent without creating problems for the prints in progress.

My rant is that most vent fans now tend to be for the cannabis growing business. I don't have any issues there, but it seems like it's a new field and that the companies selling products in it are still catching up on tech. They have proprietary bluetooth speed controls. One has wifi. People have decoded the systems, but the companies act like they've never heard of Z-Wave or other home automation protocols. I can turn a fan on and off through home automation, but speed control is not there yet. I'm hoping I can just use a low speed setting all the time. If it'll pull smoke from the CNC on a low setting, that'll be all I need.

Seems like a lot for this model. You're always welcome to post your model here (as a zip-compressed 3mf project file) to see what suggestions the friendly folks here may have for speeding things up.

I have to admit, I forget how helpful people on this forum are. This and the Blender Artists forum I use are two of the most helpful forums I've encountered on the internet in years! I really should do that - probably within the next week or so I'll post a few files and ask for feedback. I haven't yet spent much time exploring settings and dong test prints, since a lot of what I've printed needed to hold some amount of weight and I didn't want to risk issues.

RE: Large flat print is warping...

I used some of the stick of glue that was included with my printer and the print worked.

But I think I used too much glue. Did you say just a thin layer?

And I ran into a glitch. I had measured everything previously and made a change and forgot about the clearance on the bottom of the mount.

So I have to make a change and reprint.

*sigh*

RE: Large flat print is warping...

Layerneer will apply much thinner than the glue stick and will not leave any markings on the underside of the print.

For large items such as the one pictured, you don't need to coat the entire build plate surface. I will often apply Layerneer at the edges of the print, or even at the corners only, as those are the areas that typically break away from the build plate.

RE: Large flat print is warping...

Layerneer will apply much thinner than the glue stick and will not leave any markings on the underside of the print.

For large items such as the one pictured, you don't need to coat the entire build plate surface. I will often apply Layerneer at the edges of the print, or even at the corners only, as those are the areas that typically break away from the build plate.

I was thinking about that and was going to add that as a question - how much needs to be covered. I had to shorten the bottom (as in the bottom when it's attached to the monitor) and have to reprint. Cleaning the glue off was a pain and I was thinking maybe I only needed to glue down the outer parts. I wanted to add the MM ears, but I have a bevel all around it. I was thinking, in the future, I might add the ears by coming out from the flat farthest-out part of the bevel for a small distance, as a short bridge (probably about 1-2mm at most), then having it attach to the mouse ears. From what I saw, it doesn't look like the piece warped within the first few layers. I was also thinking I could attach the "ears" skirt without a solid connection so it's easier to trim.

The Layerneer gets here tomorrow, but I want to get this done so I can print some other things I need to get done, so I guess I'll try glue on the outer parts again - just a thinner layer. (With the glue stick, it's also hard to apply evenly.)

RE: Large flat print is warping...

Layerneer cleans off of the build plate easier than glue stick, I guess mainly because you don't use as much of it.

Both alcohol and detergent/water will cut Layerneer quite easily. For some reason, it seems like 'denatured' ethanol will cut layerneer a bit better than isopropyl.

However, it's very convenient to do a mostly-full Layerneer coat and then re-use it, refreshing it after each print by using an alcohol-soaked paper towel and buffing it up a bit. It will last for several prints.

It's my impression that when PLA curls up and warps, it's mostly an adhesion issue, as opposed to a shrinkage when cooling.

However, with ABS (and somewhat with ASA) there is a small but significant shrinkage which makes it notorious for pull-up and warping.

On one large print some time ago, I intentionally OD'd with the Layerneer to try to keep it from warping and pulling up, and instead of warping, it actually cracked, as in fractured, when it started to cool. Normally such a print will release cleanly when it starts to cool, but if it's held to the build plate firmly, obviously it does not.

(This was not done on a Prusa printer.)