Knocking over prints (collisions)

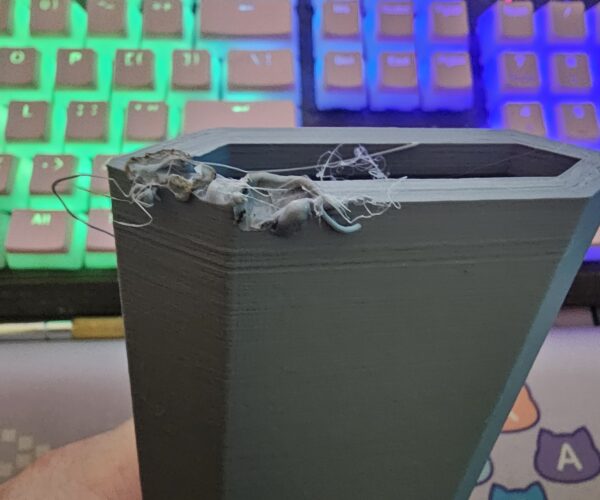

So im having issues at this exact height on prints. Not a small collision. This is the full print head melting into the print and knocking it over at like a cm too low. What the heck is going on? My layers are clean, dialed in even. What am I doing wrong?

Please save your project as a .3mf file

Files > Save Project as

Zip the .3mf and post it here. It will contain both your part and your settings for us to diagnose.

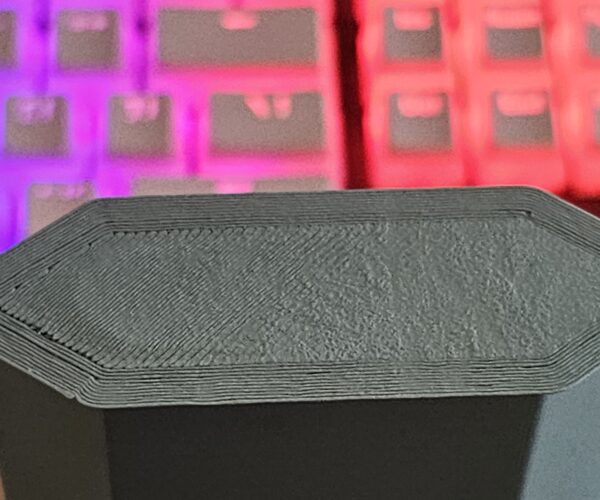

Also, a picture of the underside of a failed print might help.

Cheerio,

RE: Knocking over prints (collisions)

Added the zip file of the .3mf file.

RE: Knocking over prints (collisions)

RE:

This looks like your first layer calibration is off by bit, you are not squishing it enough, there should be no gaps between outer perimeter lanes. Additionally it looks like your bed level correction is off, as the one side is squished more than the other.

Redo the first layer calibration (lower the nozzle) and then it might be a good idea to subsequently do a bed level correction ( https://help.prusa3d.com/article/bed-level-correction_2267 )

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE: Knocking over prints (collisions)

PS: If that is not enough to get enough adhesion, even though your plate is cleaned thoroughly (IPA, if that is not sufficient cleaning with detergent), keep in mind that with tall slim parts adding a brim might be necessary. You can also resort to adhesives like magigoo or dimafix instead of or additionally to a brim.

Mk3s MMU2s, Voron 0.1, Voron 2.4

@thejiral is right. Follow those suggestions.

By the look of the underside you may be using a textured sheet with PLA - you will get better adhesion on a smooth or satin sheet if that is the case.

Also, slowing the print down will reduce the dynamic stresses and improve your chances with such a tall, thin print ratio.

Cheerio,

RE: Knocking over prints (collisions)

I did a cold pull last night and readjusted the calibration and it's okay but the tall prints are still an issue at exactly this height. The print head lowers instead of raising and it pushes the print over. That's that deep gouge in the print is the print head pushing into the model and knocking it over. It's not adhesion so much as a weird thing that the printer keeps doing, burning the nozzle into the side of a print

RE:

^^ Are you really sure about that? This an extremely narrow and very tall object with a tiny brim at the bottom (for a piece like that I would add at least 30 mm brim withou minimal or no gap between object and brim). The point where it fails seem to be very you have the internal widening which creates space for infill. Infill, is a real issue under such conditions, especially if you print infill faster than perimeters.

I would change the settings from 15% infill to 100% infill and 10 perimeters. That way, you have no erratic zigzag moves taking place so high up.

If there is really the extruder moving down within a print, do you mean it is moving a substantial way, something like several mm? Is the printer showing anything other than the regular print progress when it is doing that? Something like Error, Pause etc? If not, such down movement would have to be in the g-code, wouldn't it?

I would suggest to make the modifications I listed above and slice anew and see if it does funky stuff again. If so, it would make sense to identify the precise layer where this happens and then check the g-code manually in that layer.

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE: Knocking over prints (collisions)

yep I'm sure of it. I've made the suggested edits and tried for another couple weeks of prints and it still does it on one in 6 prints.

RE: Knocking over prints (collisions)

Another thing you can try is limiting the Y-axis acceleration and jerk; I usually just set them to the values for Z.

I make a lot of flutes, bagpipes etc with tall skinny parts and get good results this way.

RE: Knocking over prints (collisions)

Figured it out cuz of this. It was the belt. I got some belt tensioners cuz I don't have the hand strength to get the belt on the extruder tight and now it works like a charm. You were right in a way, it was the axis.