Issues with PolyMax PETG and MK3S

As a bit of background, I decided to get a 3D printer for the first time back in April of 2020. I did a bit of research, and ended up ordering a Prusa MK3S kit, which I received a few weeks later.

I haven't done what I would call a large amount of printing since, and would classify myself as an advanced novice. Perhaps partly due to the MK3S being a mostly problem-free printer (though my first print resulted in a massive blob of PLA stuck to the nozzle after printing fine for over an hour), I haven't built up a mental library of print problems and their causes.

Right now, I'm preparing to build the enclosure on the Prusa blog for the MK3S using IKEA Lack tables. I'm not far into printing the required parts, and have run into problems with groups 2 and 3 of the prints that I really don't know what to make of, in terms of how to fix it.

Here are a couple pieces from group 2:

The first shows a piece where the base is to the bottom. The second shows a piece where the base is to the left.

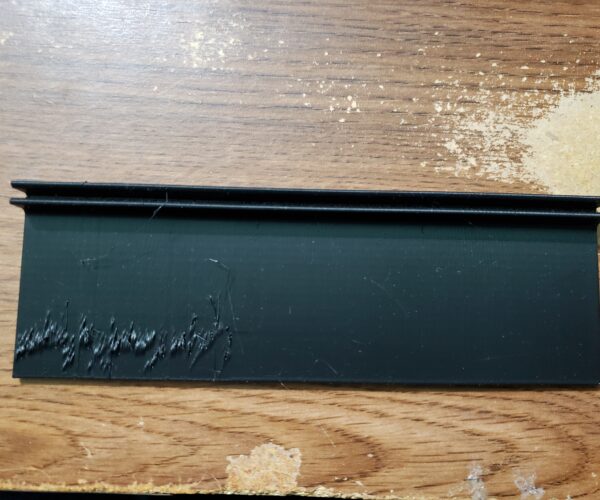

Here's one from group 3:

The base is actually at the top of the image there.

The second group (first couple images) was printed in the open in a room at about 68F (20C). The third group (third image) was printed in the same room, but with a makeshift cardboard box enclosure, which brings the temperature around the printer up to 100F (~38C). The first image shows basically no print problems for the first 60% or so of the object. Then the walls become malformed (filament bulging out), and there are two cracks mixed in. The second image shows the same bulging basically up the entire length of the object (despite being printed at the same time), with a crack and shift around 70% up from the bottom. The third image shows a long crack about 60% up from the bottom.

The filament is Polymaker PolyMax PETG. The settings used:

Nozzle: 230 first, 240 other

Bed: 85 first, 90 other

Bridges fan: 50%

Fan speed: 30% min, 50% max

Enable fan print time: below 20 sec

Min print speed: 15mm/s

Max volumetric speed: 8 mm^3/s

Retraction length: 1.4mm

Retraction life Z: 0.2mm

The nozzle is 0.4mm plated brass. I got that because I have some carbon fiber PC filament as well, and figured the brass nozzle the printer came with would be chewed up by it. Recent prints with said carbon fiber PC and PolyMax PC showed no issues beyond the difficulty of removing supports from PC.

It's winter, so the air is naturally dry. Around the printer, the humidity was 15% or lower (both in and out of the enclosure - had silica gel in a bowl inside as well). The filament is kept in a dry box when not in use.

I did hear periodic pops while printing (maybe a few per minute at most), so put the remaining filament in a dehydrator at 155F (~68C) for 6+ hours. I weighed at the beginning, and the scale used (not especially accurate) flickered between 156g and 158g, so I called it 157g. A couple hours in, and after the 6+ hours, the weight was showing as a steady 156g, so I think the filament was already as dry as it can get.

My plan is to bump the extrusion temperatures by 10C, and reduce the max fan speed to 40%, but that's just a guess.

Can anyone recognize an obvious issue with the prints that can be fixed with some settings changes?

RE: Issues with PolyMax PETG and MK3S

If I had to guess, and I do because you didn't post a (zipped up .3MF project file) I would say your model is getting floppy as it gets taller and is being pushed around a bit by the plastic being laid down at a certain height. another possible cause could be where your detraction and retractions are on the model, another could be the length of the retractions relative to where they are on the model, etc,,

Good luck

The Filament Whisperer