Issue when printing FLEX

Hi,

I am trying to print FLEX filament the first time and it's not working for me.

My problem is that the filament will not go through the nozzle. It gets stuck, or at least there is enough resistance to make it come out at the side before the nozzle (I dont know what this component is called which transports the filament).

What could be the issue? I tried using the recommended FLEX settings, but seems not working. Other filaments work without problem.

Thanks for hints!

RE: Issue when printing FLEX

Consider Flex to be your Master's degree in 3D Printing. It has its own personality.

Check your extruder and make sure the filament goes straight from the Bondtech to the PTFE.

Your extruder tension is probably OK, or it would not be bunching up after the Bondtech.

Flex hates retractions - so make sure that is all turned off.

Flex has to melt smoothly when it hits the nozzle, so run at the recommended high end - or a little above.

Cut your print speed to maybe half.

Monitor your print - so you can kill it when it bunches up.

Wait for other suggestions from others with battle scars.

RE: Issue when printing FLEX

I've found that the auto-load is a little too fast for flexibles. What I do when loading the NinjaFlex that I turn off the filament sensor and then use Pronterface to advance the filament at a slow speed like 100mm/min.

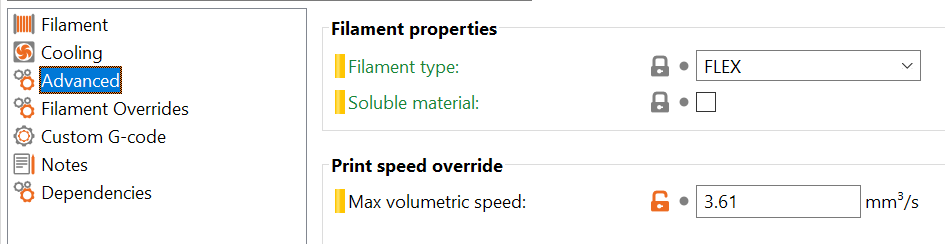

For printing I use the advanced setting "Max Volumetric Speed" to have the slicer calculate the maximum print speed for me. I found this works for my NinjaFlex (less flexible filaments may be able to get away with faster speeds):

See my (limited) designs on:

Printables - https://www.printables.com/@Sembazuru

Thingiverse - https://www.thingiverse.com/Sembazuru/designs

RE: Issue when printing FLEX

I spent the day experimenting with some Ninjaflex Eel filament. I have had very limited success. I think that replacing the PTFE tubing to make it more constrained is the best way to go but that requires some work. Im going to try and get a larger nozzle to see if that works. Let me know if you can get it to work.

RE: Issue when printing FLEX

Thank you for all your hints!

I will try my best to apply them and get it to work.

I will let you know if I succeeded.

Thank you!

RE: Issue when printing FLEX

@benedikt-n2

Make sure your filament is dry. It could also lead to bad prints. Im currently drying my filament and when its done I will try printing at a bigger layer height, could work. Another thing I saw was replacing the bowden tube to make it more constrained. If anyone else has success or tips please share.

RE: Issue when printing FLEX

If I did much printing with Flex, I would certainly extend the PTFE tube up to the Bondtech. Sharp angle at the end.

Either Guy or the Bear project have a cutting guide that I think will work with the stock extruder.

Don't give that filament even a chance to curl up on you.

RE: Issue when printing FLEX

If I did much printing with Flex, I would certainly extend the PTFE tube up to the Bondtech. Sharp angle at the end.

Either Guy or the Bear project have a cutting guide that I think will work with the stock extruder.

Don't give that filament even a chance to curl up on you.

The PTFE up to the bondtech might be part of my success. In my MK3S upgrade kit both of the provided (one to use, one spare) PTFE tubes were long enough that I needed to chamfer both sides of the top end to clear the bondtech. That leaved two little points sticking up between my bondtech gears. I guess I was lucky that my PTFE tubes happened to be on the longer tolerance end of the hundreds that Prusa was cutting for the early MK3S upgrade kits.

See my (limited) designs on:

Printables - https://www.printables.com/@Sembazuru

Thingiverse - https://www.thingiverse.com/Sembazuru/designs

RE: Issue when printing FLEX

I tried 3 weeks on my MK3s and always failed to get it to work with TPU. I ended up getting the E3D Hemera Extruder. Never had a problem ever since.

I'd say the stock extruder is just not suited for flex printing.

RE: Issue when printing FLEX

I guess I'm going to take apart my hotend and replace the PTFE tubing. Thank you everyone for your help.

RE: Issue when printing FLEX

I've had good success printing NinjaFlex using the stock MK3S setup, but it did require some adjustments in filament handling and slicer settings. I'll point you to a post I made describing my experience:

RE: Issue when printing FLEX

@mdaneman

Do you know the shore hardness of what you were printing?

RE: Issue when printing FLEX

There is also another post in the awesome prints area that bubbled up today that might help.

https://forum.prusa3d.com/forum/english-forum-awesome-prints-hall-of-fame/benchy-in-tpu/

See my (limited) designs on:

Printables - https://www.printables.com/@Sembazuru

Thingiverse - https://www.thingiverse.com/Sembazuru/designs

RE: Issue when printing FLEX

@mdaneman

Do you know the shore hardness of what you were printing?

According to its spec, Ninjaflex is 85A. It’s very stretchy.

RE: Issue when printing FLEX

"Stretchy" is almost an understatement with Flex filament.

Getting my extruder unwound, I stretched that stuff out to twice it's original length. It never did break.

RE: Issue when printing FLEX

@dimitri-3

can you post your printer settings for the flex filament and picture of extruder how it looks like on prusa? thank you!

RE: Issue when printing FLEX

I print flex filaments on my Mk3 and Mk3s all the time, both printers print them flawlessly, I have three (one at work) they are all stock. I print Ninjatek products: Ninjaflex, cheetah and armadillo on them all the time (as well as other brands) without issue. I'm using a standard brass 0.4 nozzle most of the time, but sometimes I go larger. I normally print on smooth PEI (Just because) and I use a thin layer of glue stick as a separator.

My layer height may be between 0.15 - 0.3 depending on the model. I always use the "Semiflex or Flexfill 98A" this profile is a great place to start. In this standard profile I change the bed temp to 40c (frankly it could be off) and the nozzle to 230c, (YMMV) for me I have found that these temps work with every brand and durometer/shore of flexible filament that I've tried to date.

When using the "Semiflex or Flexfill 98A" profile in newer versions of slicer you will find that your max volumetric speed is 1.35, in older versions it was 1.5 these are both good ranges with which to run your prints when your first starting out with flex. Just delete any thoughts of speed or the word "fast" from your brain, if someone even mentions the word speed in relation to flex filaments your brain should think "Speed?, whats that?, and what is this "F-a-s-t ?" you speak of. just forget about it, leave the Max Volumetric speed at default don't change anything else other then the aforementioned nozzle and bed temps. I will also mention If you have a good first layer for PLA, PETG, ASA and ABS, then you have a good first layer for FLEX, no need to change it.

Now for the physical part, to start with you should loosen your idler screw on the MK3s, and screws on the MK3 to the point that they allow you to feed your filament into the extruder by hand while pressing in on the idler tension screw, leaving just enough room for the filament to pass (better to loose to start then to tight), feed it until you see it coming out the nozzle (of course) feed it in gently, till just before you feel it bending as you push it in. Keep the wrench handy you'll most likely need it again.

Note: you can use the auto load feature with success once you get a good idea of how to handle printing these filaments for now just stick with Manual loading.

once loaded let it sit for a minute and ooze out until it stops, you should have some type of print ready. I'm going to recommend that you start with something like a 10cm X 10cm square, your first layer will print very slowly and it will give you a chance to do the next step.

Get your print and start it, as soon as your printer starts printing keep your eye on the bondtech gears, looking in the window to see if your filament is starting to kick out of the side, if it is, it means that you have your idler tension to high, loosen the gears more and try again. I normally work in 1/4 turn increments until adjusted properly.

Conversely, if the filament is not coming out of the extruder then tighten the idler a 1/4 turn at a time giving it a second to see if its extruding after each attempt. I'm going to recommend that you start loose to the point that its probably not going to extrude, and work your way towards extrusion, rather then starting off possibly to tight and having to stop the print and clean out the gears. This is why I recommend a large flat square.

Once you feel like you have a good extrusion going on and your first layer looks nice, try printing it again from the start and see how the full print goes, always keeping an eye on the bondtech gears until your sure you got it.

Note: it can happen that your tension is just the tiniest bit to tight, and a back pressure will build very slowly causing the filament to eventually kick out of the side several layers into a print, it should go without saying, but you need to loosen the Idler a bit if this happens. {not rebuild your printer}

Once the tension is set I normally don't even have to change it between filament types, it tends to work for all e.g. PLA, ABS, PETG, ASA etc,, on occasion if I do need to tighten or loosen, it's normally not more then a 1/4 turn and in extreme cases a 1/2 turn of the idler screw. This process takes me about 5 minutes on average, if for some reason I had to open the idler door and reset the tension on the bondtech gears, I've gotten pretty good at it, and sometimes only use a small circle to make sure it's right.

You should expect it to take some time to get a handle on printing flexibles start out with higher durometer filaments they are a bit easier.

Do yourself a favor and make sure your printer is ready to go (well tuned) clean nozzle etc,, if your still having trouble printing PLA and PETG then maybe hold off on flexibles for a bit till you get the basics down.

Anyway this is my experience, maybe it will help someone.

Enjoy and good luck

The Filament Whisperer