Is this even possible?

Hi there,

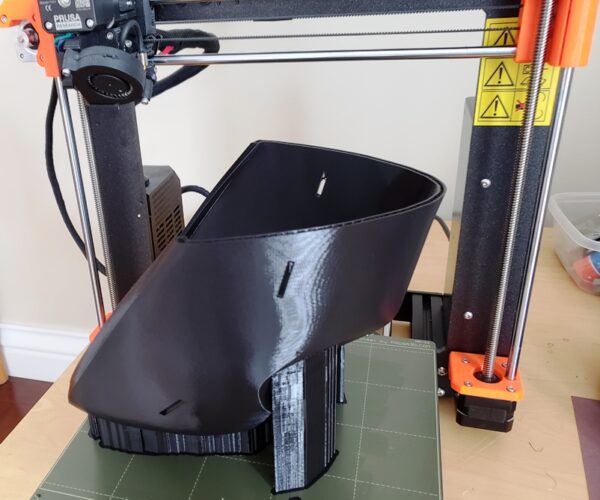

I've tried to print this mask in one go. It was a very tight fit on the MK3 but everything was going fine. Total print time, 35h33. I was not sure my spool would have enough filament to finish the job and the print was set to finish in the middle of the night.

When I got up for a bathroom visit, I've check on the job and the print was stop because it runs out of filament. Being impatient has I am, I decided that I would fix the issue while half awake. Y'a, not a good plan.

So, has it append from time to time, the little string of filament from the depleted spool did not came out of the extruder. I had to use a pair of plyer to extract it. It's at this step that I messed up. The extruder was all the way in the right corner and I push it a little to the left to get a "better angle" to remove the string. Doing so, I've made the printer lost its "bearing" and when I resume the print, the printer started printing in thin air and not on the object. 😑

The print is nearly finished, less than 3 hours to go. I would print the missing part but the whole point of this project was to not have to assemble any parts in the post process. So, is there a way to "trick" the printer to finish the job with a "special" G-code? I don't hold my breath on this one but I ask anyway just in case it's feasible.

RE: Is this even possible?

I have been told, but I have never done this, that you can manually edit the .ccode, IFF you know the layer at which the disruption occurred, and resume the print with only one layer that is questionable.

I have never tried it. YMMV!

RE: Is this even possible?

I've tried it a handful of times and each time failed miserably....

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Is this even possible?

i can recommend the guide from cnc kitchen

RE: Is this even possible?

I suspect that using the cut function in Prusaslicer to isolate the unprinted section then joining the two halves together is about as good was you'll get. Maybe add a few tabs to align the parts.

RE: Is this even possible?

It will still require some gcode editing. In particular you will need to turn off the bed leveling and anything else that will slam the extruder in to the existing print.

RE: Is this even possible?

Thank you all for your answers!

I've check the video posted by pokon_nurdspace and I've found this other one that pretty much show the same things

After watching those and with my situation, I think I could have successfully resume the rest of the print.

But I was a bit impatient (again) and I finish the last part on a separated print before seeing those videos. 😶

On the bright side, if I ever mess up like this again, I know now I can at least try something.

As for the second part, after taking note of the time remaining for the print, I pretty accurately spotted at witch layer height this part should started in a G-code viewer. And since the first print stopped precisely between two layers, the two parts fit seamlessly.

RE: Is this even possible?

A project for someone who has a lot of time might be to either add a 'resume print at level N' function to the firmware, or a similar function to PS to generate a .gcode file to do just that.