How to improve resilience of slim objects printed vertically?

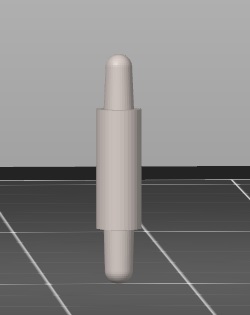

I am trying to solve problems related to small and thin cylindrical objects printing.

I need to print a pin with diameter 1,5 up to 3 mm

I need an object with good tolerances on diameter and circularity,

I already tried to print the pin horizontally but it comes out deformed.

The I also tried to print it horizontally in 2 halves but merge the parts after print is very messy.

so I printed it vertically but the pin is extremely fragile,

trying to bend it by hand cause immediately a layer detachment and pin broke in half.

I do not want to use supports in order to reduce post processing.

Is there any advice to increase mechanical properties of this kind of items?

Like disabling cooling, or increasing it, or change any setting on prusa slicer?

You don't say which filament you are using but be aware that some have better interlayer adhesion than others. Printing at 45 degrees will vector some stresses across layers, it might help.

Cheerio,

RE: How to improve resilience of slim objects printed vertically?

I just don't think you will get strong pins at that size no matter what material you use. The only orientation to get the circularity is either vertical or at a slight angle. That puts all the stress on the layer adhesion, the weakest vector. Depends on what they are used for which you haven't mentioned. Just what load are they under ?

A 1.5mm is tiny for a 0.4mm nozzle, it might get better with a 0.25. Would be an interesting experiment at least.

I just think this is the wrong technology to do this. Maybe one of the tough resins in a SLA printer.

RE: How to improve resilience of slim objects printed vertically?

Is there any advice to increase mechanical properties of this kind of items?

Make this part hollow and insert metal in it (a nail, a screw, or thick wire).

RE: How to improve resilience of slim objects printed vertically?

Thanks a lot for your feedback.

I will try to implement your advices, I think that usign a metal core can be very tricky but worth a test

Before that i will try to change vertical alignement to an angle that will not require supports

I had a test once and the thin part of the pin broke, anyway I can test some different angles

Printing the pin horizontally results in a strong pin that I can't break by hands, but the result is an oval section

in the segment wiht diameter 1,5mm I get radius error (along Z) around 10% less than nominal dimension

in the segment with diameter 3mm I get radius error (along Z) around 3-5% less than nominal dimension

So if I compensate smaller daimeter I will overcompensate the bigger one, there is not a uniform deformation of geometry.

Materials I am using are PLA+ and ABS, the nozzle is 0.25mm and in some test 0.15 by E3D

This last experimental nozzle is cool but is very difficult to find the right parameters on prusaslicer

and I see that here on the forum not many people tested this extremely small nozzle.