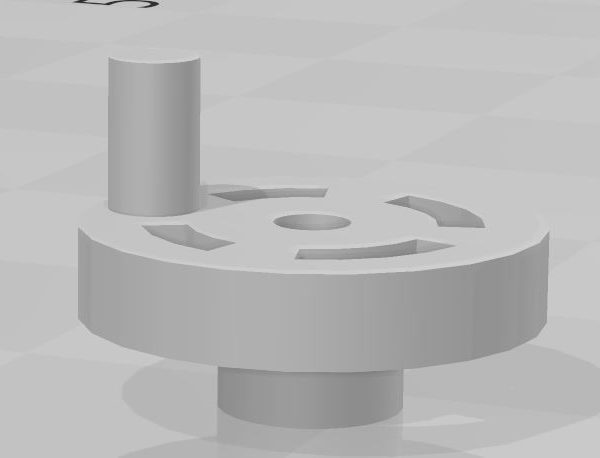

How do I print something like this?

How do I print something like this? When it gets to the larger part of the handle it just squirts out filament into thin air.

Best Answer by dwisejr:

Need to add supports and make sure you set the “Contact Z distance” under “Print Settings/Support material” to .2mm.

Thank you! Do I need to add the supports in the drawing, or in the slicer?

RE: How do I print something like this?

Need to add supports and make sure you set the “Contact Z distance” under “Print Settings/Support material” to .2mm.

RE: How do I print something like this?

Need to add supports and make sure you set the “Contact Z distance” under “Print Settings/Support material” to .2mm.

Thank you! Do I need to add the supports in the drawing, or in the slicer?

RE: How do I print something like this?

Need to add supports and make sure you set the “Contact Z distance” under “Print Settings/Support material” to .2mm.

I found it. Thank you very much!

RE: How do I print something like this?

In the Slicer. The part with supports is usually not so nice and precise. So based on what should the part do choose right orientation of the model.

RE: How do I print something like this?

.2mm z distance usually is very clean for me. I would print it as you have it shown above and just clean up anything left behind with a file or sandpaper. You could rotate it on edge with the pin horizontal to minimize support contact. Not sure your use for this, so hard to say. Diameter will be more accurate as shown, but pin would be stronger if laid horizontal. It’s all a trade off.

RE: How do I print something like this?

I printed a small version of this Scrooge bust, but larger ones aren't working. #1 printed for a couple hours and then started printing off to the side. #2 printed for over 10 hours and then did the same thing. #3 is a medium size version which I came home and found laying on the printer as depicted in the photo.

Anyone have any idea what might be wrong?

RE: How do I print something like this?

Looks like you are having crash problems. Usually these turn out to be dry bearings that have too much friction.

Use the menus, read the "belt tension" numbers and post them. If they are less than 260, you need to look into lubricating the bearings and rods (the numbers actually have nothing to do with belt tension: the guy that designed the filament sensor worked on this part of the code).

RE: How do I print something like this?

@tim-m30

Thank you for the reply. I found the settings. X = 255 and Y = 275. I am reading some about it online right now.

RE: How do I print something like this?

I printed the 8 inch tea cup in the attached photo with no trouble. I printed it right before the first failed Scrooge print (photo #2).

I cleaned and lubricated the rails and tried tightening the grub screws on the X and Y motors, but they didn't seem lose.

I'm over half way finished printing "buddy-0-15-mm-pla-mk-3" right now and it looks ok so far.

BTW: I purchased my Prusa i3 MK3 assembled, not as a kit.

RE: How do I print something like this?

Prusa, for whatever silly reason, believes the oil the bearings comes in is a lubricant. You can ask any manufacturer and they will immediately say Prusa is wrong. It's a simple antirust oil that is compatible with many common greases. Bearings must be cleaned and greased before installation.

Without grease, the bearings dry out and seize. This drying process takes weeks to months. When they seize, the stepper motors stall. If crash detection is off, the printer recovers, but now prints X or Y stall stalls away from where it should. The offset you see in your prints shows a fairly major stall.

Cover the print bed with a few paper towels and drip some machine oil onto the rods and work the axis back and forth. You need to do this a few times to get the oil past the grease seals and inside to lube the ball bearings inside.

Once is a while, the extruder case is warped or deformed or wrong size and loosening the rear screws near the bearings can relax things enough it reduces friction. But lubrication is generally the problem with shifts.

There is also a firmware bug; and turning off the filament sensor can help with that.

Anyway - these type of problems (sticky bearings) are common; and intermittent (they come and go at the best of times). But now you know how to deal with it when it becomes an every other print problem (and you know with that 255 value you have high friction).

RE: How do I print something like this?

ps: it is also possible curl caused the shift: unlikely, but possible. Print a solid layer over infill - and gyroid is one of the worst for this - edges of the layer fill will curl up and grab the nozzle as it passes by. You can usually hear the nozzle clicking on the plastic as this is happening. An occasional snap that gets louder as the curl grows. If you tried less than 15% infill, the risk grows.

RE: How do I print something like this?

Prusa, for whatever silly reason, believes the oil the bearings comes in is a lubricant. You can ask any manufacturer and they will immediately say Prusa is wrong. It's a simple antirust oil that is compatible with many common greases. Bearings must be cleaned and greased before installation.

Without grease, the bearings dry out and seize. This drying process takes weeks to months. When they seize, the stepper motors stall. If crash detection is off, the printer recovers, but now prints X or Y stall stalls away from where it should. The offset you see in your prints shows a fairly major stall.

Cover the print bed with a few paper towels and drip some machine oil onto the rods and work the axis back and forth. You need to do this a few times to get the oil past the grease seals and inside to lube the ball bearings inside.

Once is a while, the extruder case is warped or deformed or wrong size and loosening the rear screws near the bearings can relax things enough it reduces friction. But lubrication is generally the problem with shifts.

There is also a firmware bug; and turning off the filament sensor can help with that.

Anyway - these type of problems (sticky bearings) are common; and intermittent (they come and go at the best of times). But now you know how to deal with it when it becomes an every other print problem (and you know with that 255 value you have high friction).

Thank you so very much! I will try the oil right away. And I will let you know if it works (takes a long time for that print).

Thank you again.

RE: How do I print something like this?

ps: it is also possible curl caused the shift: unlikely, but possible. Print a solid layer over infill - and gyroid is one of the worst for this - edges of the layer fill will curl up and grab the nozzle as it passes by. You can usually hear the nozzle clicking on the plastic as this is happening. An occasional snap that gets louder as the curl grows. If you tried less than 15% infill, the risk grows.

Thank you so much. I'm noting all of this.

RE: How do I print something like this?

Prusa, for whatever silly reason, believes the oil the bearings comes in is a lubricant. You can ask any manufacturer and they will immediately say Prusa is wrong. It's a simple antirust oil that is compatible with many common greases. Bearings must be cleaned and greased before installation.

Without grease, the bearings dry out and seize. This drying process takes weeks to months. When they seize, the stepper motors stall. If crash detection is off, the printer recovers, but now prints X or Y stall stalls away from where it should. The offset you see in your prints shows a fairly major stall.

Cover the print bed with a few paper towels and drip some machine oil onto the rods and work the axis back and forth. You need to do this a few times to get the oil past the grease seals and inside to lube the ball bearings inside.

Once is a while, the extruder case is warped or deformed or wrong size and loosening the rear screws near the bearings can relax things enough it reduces friction. But lubrication is generally the problem with shifts.

There is also a firmware bug; and turning off the filament sensor can help with that.

Anyway - these type of problems (sticky bearings) are common; and intermittent (they come and go at the best of times). But now you know how to deal with it when it becomes an every other print problem (and you know with that 255 value you have high friction).

The oil seems to have done the trick. After two long failed prints, the third attempt finished this morning.