Help with some print quality issues

Hello,

I have had an i3 MK3S (currently using firmware 3.9.3) for two years now and for the most part have had excellent results. I have exclusively used Prusament PLA and PETG and PrusaSlicer (currently 2.3.0) with the stock filament settings. Not sure if it would be relevant but I also use OctoPrint v1.5.2 on a Raspberry Pi 3 connected via USB.

Within the last couple of months I started to see some printing issues that I am not quite sure how to fix and was hoping you guys could lend a hand. I plan on doing a full servicing of the printer when I get the MK3S+ upgrade kit but could use some help until it arrives.

My first issue is filament oozing and to a lesser extent stringing, especially when printing Prusament PETG, even using a brand new spool. My oozing is not like the typical scenario as described here. My prints are much better than the examples in that article with minimal stringing. My oozing occurs while waiting for the bed to heat up after the nozzle as reached full temperature. When I start a print I make sure there is no filament oozing from the nozzle (0.4) and by the time the extruder and bed reach the default temps (240/85), there is around 90-100mm of filament hanging from the nozzle. I usually pull this filament off right as the printer starts the bed leveling self test and even then many times filament will still ooze out and get built up on the nozzle before it starts printing. This sometimes leads to globs in the print and can even cause it to fail if a big chunk happens to stick to a layer as it's printing. This has even occurred for me immediately after putting on a brand new nozzle.

As I am using the Prusa official preset settings in PrusaSlicer and Prusament I am hoping someone can give me some suggestions on what I might need to do. I believe I could try tweaking the retraction settings or adjusting temperatures but I use Prusament specifically because of those official presets so I can avoid these types of issues. As I didn't really have any issues when the printer was new and it now seems to be getting worse over time I am wondering if I need to do some tests to see if something on the printer needs repair or tightening up?

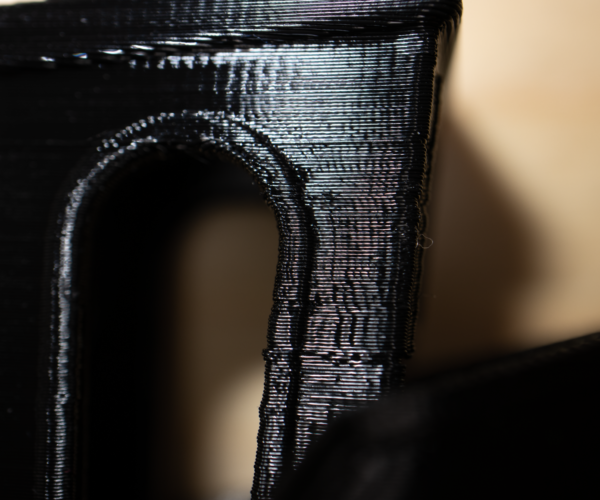

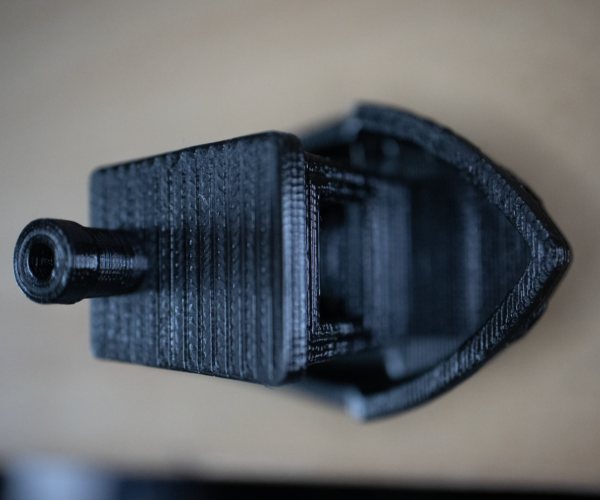

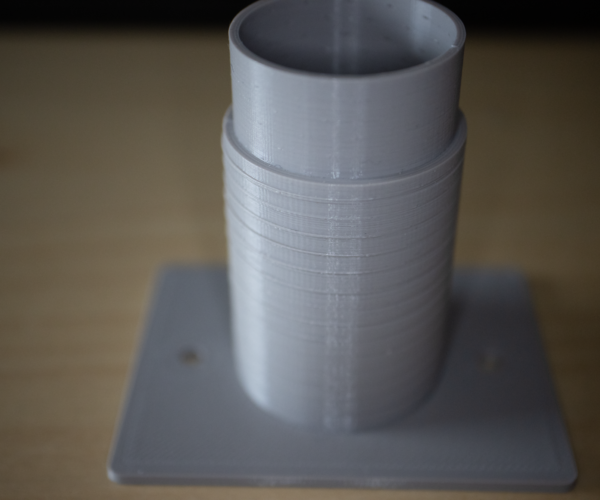

My second issue has become more of a concern for me in the last couple of weeks. I appear to be having a strange layer shift issue but not one that is typical as shown here. The layer shift I'm having is much slighter than those. For example when I print a 3DBenchy the body of the hull has no layer shifting but the 4 verticals of the cabin don't have clean lines and are a little wavy. I really see the issue when I print parts that have hollow cylinders in them, though only when they have a large diameter. For example the 3DBenchy chimney looks very good but if I print a hollow 30mm diameter support post I get banding in the layers every couple millimeters or so. I suspect this may be related to my belt tensions or perhaps something is loose on the print head from changing the nozzle. Before I go and start messing with everything I wanted to see if you guys had any suggestions?

One other thing that came to mind regarding my first issue is I've always noticed is that the extruder and bed heat up at the same time but the bed always takes longer to heat up while the extruder sits at full temp. Perhaps one way to mitigate the oozing issue would be to have an option in the firmware to only heat up the nozzle once the bed reaches a certain temperature so they reach operating temperature at roughly the same time and minimize how long the nozzle sits at full operating temperature.

I will follow up with a reply including some pictures of recent prints so you can see what I am describing above.

For whoever reads over all of this thank you for your time and any information or suggestions you might have would be highly appreciated.

Thanks,

Bryan

RE: Help with some print quality issues

The oozing during heat up has been covered to death and on an almost weekly basis. Please try using the search function as a number of forum members have gone into great detail on remedies for common issues.

Here is one from last week with the gcode you need to edit in the slicer:

An update since I post my response in that one is, change the firmware check line to 3.9.3 as this is now the latest firmware.

The gcode will also make sure the PINDA is warmed up before doing the bed mesh level. This makes sure it always starts the bed mesh level from a stable environment.

Try this out and see if it makes a difference.

On the MK3S+ upgrade kit, even Prusa say, If you have an MK3S that is printing well, the + upgrade will be of no advantage to you. They're aimed at people with older model printers.

RE: Help with some print quality issues

Thank you for the suggestions I will see how that helps my print quality. I see in those options your basically doing what I was asking about (heating the bed before getting the extruder to print temp). I did a test and just set nozzle temp to 150 and let it sit for five minutes and no oozing so I would say this should fix that issue so I've updated all my custom printer profiles.

Do you happen to know if Prusa intends to update the default Startup G-Code so we don't have to maintain custom profiles for this one fix?

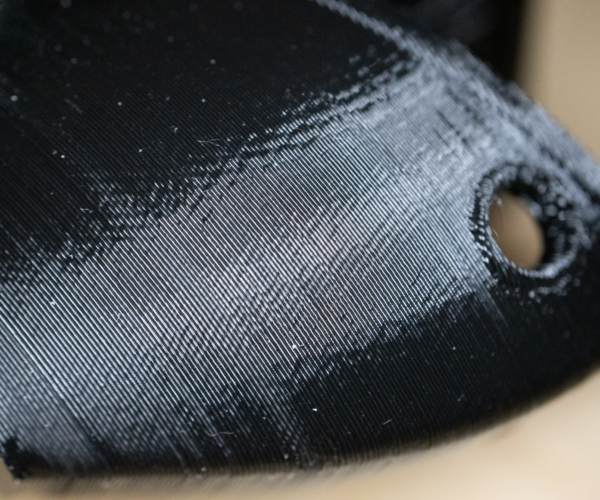

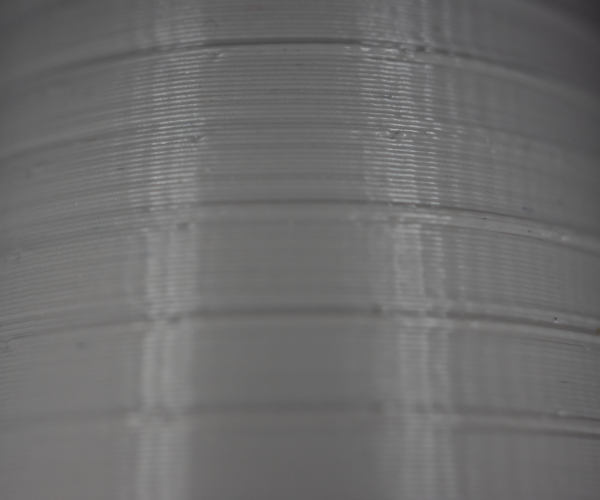

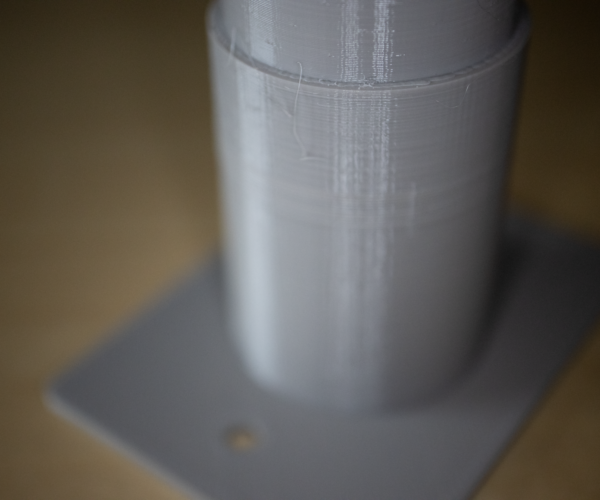

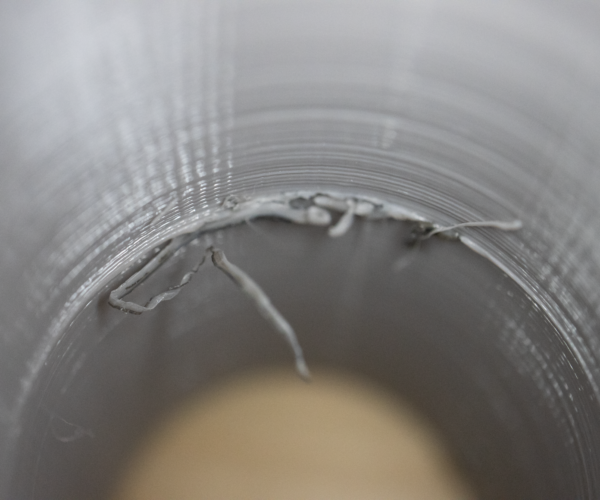

Also, I have taken the pictures I mentioned previously. If you don't mind taking a look any advice you can give to correct these issues would be greatly appreciated. I've attached the 3DBenchy, which for the most part looks pretty good, a few small issues aside. The cylinders I've attached show the issue I'm having with layer shift pretty significantly.

I did a search and found this post about a loose heat block and heat break, which would make some sense as after changing the nozzles a few times my heat block does seem to be a bit loose and this also this seems to coincide with the quality issues I've seen.

I also think I may need to adjust the belt tensions but I'm not sure as I'm not seeing drastic layer shifts. I ran the belt check multiple times and X averaged 250 and Y averaged 275. I know these are both within range but figure it might make sense to recheck the tensions on both and see if by feel and by the belt check I can get them closer in tension.

Between those two suspected issues I've mentioned and based on these pictures below do you feel there is any other things I should be checking to get the print quality a bit better?

Also, in regards to the MK3S+ upgrade kit, I was considering getting it because I had thought the MMU2S required it but on closer reading I see they are saying MK3 users need the upgrade kit so it looks like I would not need the kit as you've said once I figure out why my printer is not working correctly at the moment.

Thanks again for your help!

RE: Help with some print quality issues

OK.

Looks more like extrusion issues than layer shift to me, but @bobstro is the grand master on that topic.

Judging by what your describing through about the hot end, I would suggest rebuilding it.

Chris Warkocki has a great YouTube video on it:

RE: Help with some print quality issues

I think rebuilding the hotend might solve your problem. After few years the thermal compound that you have at the interface between heatbreak and HeatSink degrades, making that the heatbreak is not cooled properly anymore.

You can use the same type of thermal paste that you use for CPU heatsinks (something like Arctic Silver, Thermal Grizzly, Cooler Master, ...)