RE: Help printing Taulman Alloy 910 nylon (print "tapers")

Hans,

Thanks for the advice. I have already ordered the tofnol sheet - never mind it wasn't very expensive.

Like you I have had success with eSun PC on the smooth PEI sheet with PVA glue. No issues with curling or lifting.

I will try the Nylon using the method you have specified and see how it goes. I have yet to buy Nylon filament so it might be a while before I report back.

Cheers

Rick

RE: Help printing Taulman Alloy 910 nylon (print "tapers")

Hi Hans,

I decided to follow your advice and canceled my order of the Tufnol sheet. I recently received a roll of eSun ePA-CF (Nylon reinforced with carbon fibre) and decided to try your method. I used my smooth Prusa PEI sheet with the Prusa supplied glue stick. I used PrusaSlicer with Taulman settings to prepare a 50mm cube at 0.2mm layer height with single walls and base, no infill or top layer. 0.6 Nozzle (new Tungsten carbide Nozzle from Spool 3D in Canada) and nozzle temperature set to 250 and bed to 80 degrees. Filament was fresh from bag and not dried by me (I usually dry overnight first but was too impatient this time).

Results were great. Cube was adhered so well I needed to use a plastic spatula to remove it. No warping and a good finish. Very impressed with quality of print considering I have carried out no tuning.

Investigations continue.

50mm Hollow Cube printed with eSun Nylon CF.

Thanks

Rick

RE: Help printing Taulman Alloy 910 nylon (print "tapers")

Hi Rick,

Good to hear you are having success. I found the Nylon CF does not shrink at all and is easier to print than straight nylon.

Did you rough up the PEI sheet with 800 grit sandpaper as I did?

I am currently designing an electic trike (pedal assist) and have just finished the design and printed out the front suspension using ESun CF nylon. I will now mount it on a test chassis for structural testing.

I found that using 260 deg C for the nozzle temperature gave best layer adhesion.

The only thing I found is that the XY dimensions "squish" out by o.25 mm which I have to take into account when designing the components.

Hans

RE: Help printing Taulman Alloy 910 nylon (print "tapers")

Hi Hans,

I did not rough up the PEI sheet with sandpaper. I'll try the higher temperature next time I print. I'm using a Tungsten carbide nozzle which is reputed to have good heat conduction so higher temperatures might not be so necessary.

My dimensions are 50.1mm at the base (slight elephant's foot) and between 49.97 and 50.00 everywhere else - magically precise. The dimensional accuracy may change when I print more solid prints due to shrinkage. I will try a calibration cube with infill next.

Rick

For Sucha small and thin print it's super strong. I am unable to break the single layer cube sides at all (using my hands) - the base is weaker bthough - presumably ecause the layer is compressed and thinner for bed adhesion.

RE: Help printing Taulman Alloy 910 nylon (print "tapers")

Hi Rick,

Interesting to see the accuracy you are getting. I don't seem to have any shrinkage with the CF nylon just the constant XY .25mm to the sides. Could be the nozzle or the settings. I am using a hardened steel 0.6mm nozzle with a layer height of 0.25 . If I print threads I use 0.20 mm.

It was the Taulman Alloy 910 which I had shrinkage problems with and also adhesion problems which prompted me to try roughing the PEI sheet with sandpaper which seemed to work. It seems for the CF nylon this does not seem to be necessary.

I have just finished the design and printing of an E trike that I am building. The whole suspension is printed with ESun CF. I have bounced on this with my whole weight and nothing looks like failing. I have attached a picture for your interest.

Hans

RE: Help printing Taulman Alloy 910 nylon (print "tapers")

Hans,

That's a great looking design. Very solid and utilitarian. The finish on the parts looks fantastic. I don't have any functional jobs at the moment to try the nylon with but I am very confident now that it will print well.

I note from eSun's product brochure that it has a glass fibre reinforced nylon, ePA-GF that seems to have higher strength and stiffness than the ePA-CF. Have you tried this filament?

Regards

Rick

RE: Help printing Taulman Alloy 910 nylon (print "tapers")

Hi Rick,

No, I have not tried the GF filament. Did not know that GF stood for Glass Fibre. It seems strange that the glass fibre reinforced filament is stronger than the carbon fibre filament. Does not seem logical to me. There does not seem to be any information on the web of people using the ESun filaments. I have just purchased three rolls of the ESun CF filament so I don't think I will try the GF for a while.

Hans

RE: Help printing Taulman Alloy 910 nylon (print "tapers")

Hi Hans,

Sorry for the late reply. My supposition, not supported by any evidence: The carbon fibre is very finely chopped and adds to dimensional stability but not much to overall composite strength as the fibres are so short. The glass fibre is in much longer lengths, and while ultimately not as strong as carbon fibre the longer fibre length contributes more to overall Nylon/Glass composite material strength.

Until I get some Glass Fibre Nylon to try out and inspect that will remain as supposition and open to challenge from all!

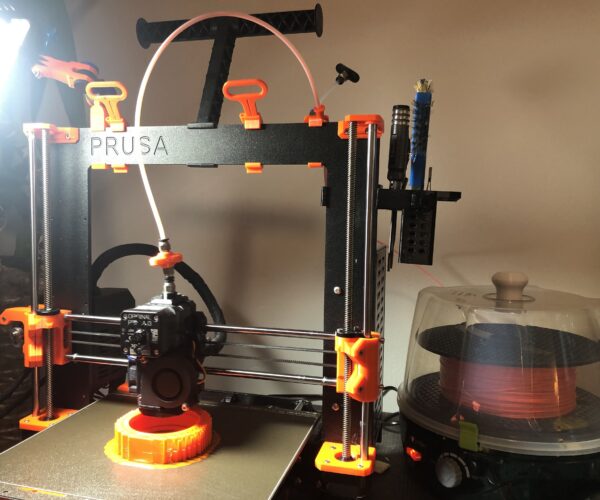

Here's a picture of my completed Nylon printing station - with home upgraded food dehydrator to keep the filament dry.

PS: I've noticed that adhesion is still amazing although I've used up almost all of the glue on the bed. The eSun CF Nylon is really very easy to print.

Nylon printing station

Nylon printing station

Cheers

Rick

RE: Help printing Taulman Alloy 910 nylon (print "tapers")

Hi Rick,

Good about the adhesion. I found that after a while the adhesion seems to get less and a good cleaning is required. I saw an idea on Youtube about heating the bed to 60deg C and laying a wet paper towel over the sheet for a while to make removing the PVA glue easier. I am using a microfiber cloth soaked in water which seems to work. I then scrub the sheet with Isopropyl Alcohol and a paper towel until there are no more printed part shapes visible and then I paint on a thin layer of PVA with a brush. I notices also that somepeople for a thorough cleaning also use steel wool occationally which probably will replace the sanding that I use.

Interesting to see how people keep the filament dry. I use a food dehydrator to dry the filament if I think it has been lying around for a while. I then put the roll on a spool holder in a see through plastic drum which also holds a dehumidifying container. Attached photo of my print station.

Cheers

Hans

RE: Help printing Taulman Alloy 910 nylon (print "tapers")

Hi Hans,

That’s a nice looking enclosure. I need to make one as I am getting requests for ABS prints and I know one is required for that.

Regarding the glue, I’ve just been adding a few drops of water on the bed after each print and smearing the glue around with a wet paper towel. I’m amazed that it’s still working OK. I printed some extruder parts in the ePA CF yesterday after doing this and they worked out beautifully.

I checked with my eSun supplier. He said that eSun are not selling the ePA-GF yet even though it is in their catalogue. I guess that’s why there isn’t much information about it on the wider web.

Regards

Rick

RE: Help printing Taulman Alloy 910 nylon (print "tapers")

Just in case someone is still struggling with Taulman Alloy 910 here is my experience:

-> Heat chamber (>35C)

-> Heat bed 90C

-> Regular PEI sheet with glue stick

-> 270C nozzle temp

-> Slow print (~30mm/s max)

-> Print one object at a time avoiding crossing layersI'm getting nice shiny/sturdy parts. The part sticks to the bed but it tend to warp slightly depending on the geometry.

Just as a hint, don't hesitate to bump up the temp beyond the suggested temps. Sometimes you will get even better results.

I purchased a 10m sample, I used your settings, the print came out great although the filament was very wet and no enclosure. the print took about 3 hours. I also printed a 50 x 10 x 8 mm piece which I could not break. After a lot of twisting, I just managed to get a little delamination.

This stuff is perfect for my application, previously I tried NinjaTek Armadillo which was tough but very hard to print, also very slow.

RE: Help printing Taulman Alloy 910 nylon (print "tapers")

@aureumlocus

I would be concerned about any enclosure where the PSU in particular, but also front panel and EINSY electronics are kept within the enclosure, as the elevated ambient could decrease the life of components. For my enclosure I relocated the PSU and added a duct + fan to get cool air onto the EINSY. The front panel is outside. The enclosure is a bit complicated as a result and maybe not as efficient but ABS prints great and I'm confident that my electronics are not being damaged.

RE: Help printing Taulman Alloy 910 nylon (print "tapers")

@thomas-f17

Thanks for the advice. I have a Prusa Lack enclosure now with the power supply outside. The display and Einsy board are inside but I have read that the 30 to 40 degrees reached inside the enclosure is well within the limits of those boards?

RE: Help printing Taulman Alloy 910 nylon (print "tapers")

@nikolai-r

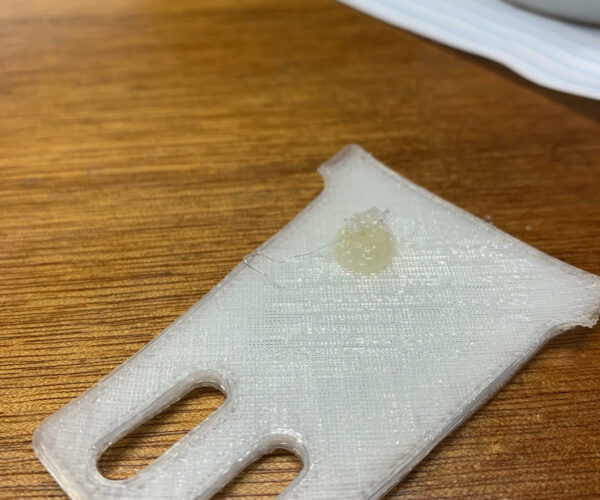

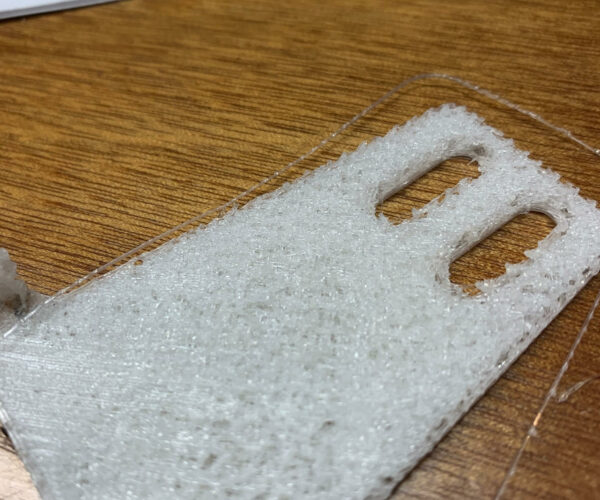

Old thread but I gained a lot by reading it. I am still having problems. I'm trying to print Taulman Nylon 910 using the smooth sheet. Have tried various temp settings from 250-270, also various bed temps. After drying the filament at 55C for 48 hours, I have decent adhesion, but the prints still are not working at all; I don't even know what word to use to describe this failure; the result almost looks like I am printing velcro:

I was originally using steel nozzle, so I switched back to brass, same result.

Do you all have any guidance of what this failure is? What settings should I try to experiment with?

RE: Help printing Taulman Alloy 910 nylon (print "tapers")

@causey

Wow, that's a pretty wild looking print! I really don't know what is going on, but one thing I found helped when I was having problems was to increase the layer width. It may be set automatically or you may have specified a width, but try doing a trial where the width is set to about 1.5 x nozzle diameter. And minimal or zero cooling.

RE: Help printing Taulman Alloy 910 nylon (print "tapers")

@nikolai-r

Old thread but I gained a lot by reading it. I am still having problems. I'm trying to print Taulman Nylon 910 using the smooth sheet. Have tried various temp settings from 250-270, also various bed temps. After drying the filament at 55C for 48 hours, I have decent adhesion, but the prints still are not working at all; I don't even know what word to use to describe this failure; the result almost looks like I am printing velcro:

I was originally using steel nozzle, so I switched back to brass, same result.

Do you all have any guidance of what this failure is? What settings should I try to experiment with?

What slicer are you using and if you’re using Prusaslicer which filament profile. Try no part fan. I’d be tempted to contact Taulman.

my last print I did with Taulman 910 I didn’t dry, I based the filament profile on Taulman Bridge, no fan, 270c. The finish could have been better but was good enough.

RE: Help printing Taulman Alloy 910 nylon (print "tapers")

I did use a dehydrator, not sure made any difference to drying?

RE: Help printing Taulman Alloy 910 nylon (print "tapers")

@nikolai-r

Old thread but I gained a lot by reading it. I am still having problems. I'm trying to print Taulman Nylon 910 using the smooth sheet. Have tried various temp settings from 250-270, also various bed temps. After drying the filament at 55C for 48 hours, I have decent adhesion, but the prints still are not working at all; I don't even know what word to use to describe this failure; the result almost looks like I am printing velcro:

I was originally using steel nozzle, so I switched back to brass, same result.

Do you all have any guidance of what this failure is? What settings should I try to experiment with?

What slicer are you using and if you’re using Prusaslicer which filament profile. Try no part fan. I’d be tempted to contact Taulman.

my last print I did with Taulman 910 I didn’t dry, I based the filament profile on Taulman Bridge, no fan, 270c. The finish could have been better but was good enough.

Good to know that you had decent results with the 910. I started with the Taulman Bridge profile in Prusa slicer and went from there. I'll try again but at 270 this time.

RE: Help printing Taulman Alloy 910 nylon (print "tapers")

@causey

Wow, that's a pretty wild looking print! I really don't know what is going on, but one thing I found helped when I was having problems was to increase the layer width. It may be set automatically or you may have specified a width, but try doing a trial where the width is set to about 1.5 x nozzle diameter. And minimal or zero cooling.

Layer width? Do you mean extrusion width? I haven't modified that before; will give it a try!

RE: Help printing Taulman Alloy 910 nylon (print "tapers")

So, using standard extrusion width parameters and 270C extruder temp yields the same bad print. My nozzle is .4mm, so I set extrusion width to be .6; with this change at least the print is now cohesive enough for me to start having warping problems, which is an improvement. 🙂 I'll give it another try but managing the adhesion issue better and see what happens.