Help printing Taulman Alloy 910 nylon (print "tapers")

Hi.

I'm trying to print a tube with some bevels but am not getting the result I want.

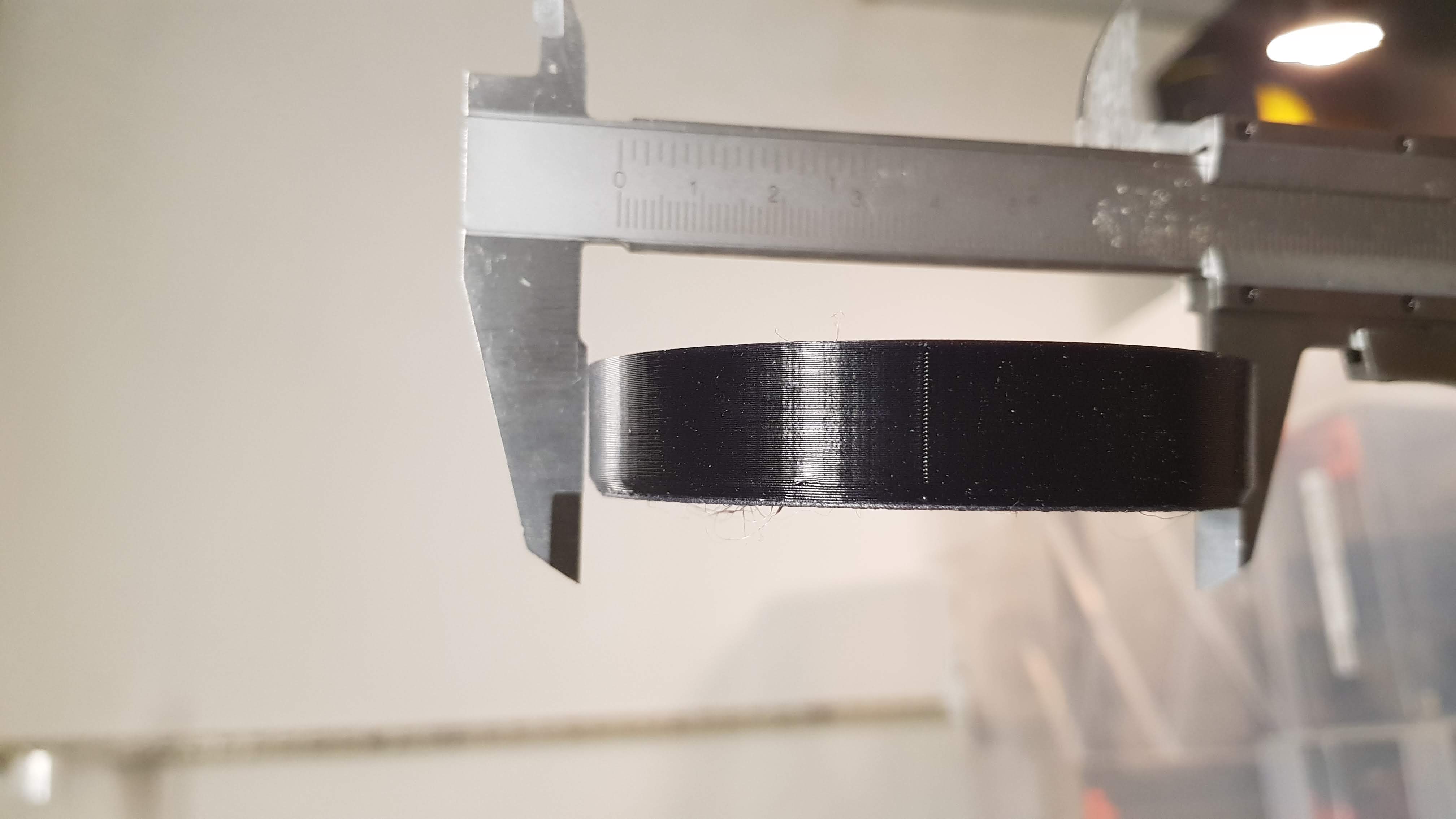

This is what the actual model looks like. Straight cylinder (15mm height) with bevels top inside and bottom outside.

This is how it looks. It doesn't leave the bed or anything but it expands at the top/bottom.

I tried printing with a raft and got this

Which looks good at bottom but expands as it gets higher.

I'm using an enclosure, no fans, glue on bed 75c, 250c nozzle, 0.2mm layer height and printing rather slow (this took 1.5h to print)

Any ideas?

Re: Help printing Taulman Alloy 910 nylon (print "tapers")

straight nylon can warp a lot, you might consider heating the enclosure.

cf blends are much less susceptible to this. i'm printing colorfabb cf nylon right now with no bed heat at all.

Re: Help printing Taulman Alloy 910 nylon (print "tapers")

Hi Martin,

I'm printing with Alloy and have seen this tapering.

It could be a number of issues but generally, if you nail the bed adhesion and ambient temp of 40-50c this tapering (pulling) will not occur.

This is my setup

• I run a dehydrator full time (maybe not necessary but it’s nice to have)

• Print on Tufnul with nitro wolfbite, in an enclosure

• Nozzle 255, bed 40 to 50, I adjust the bed temp depending on ambient, always aiming for 50c

• Speed and retractions settings as per attached screen grabs

• 0.6mm nozzle @ 0.2 layer height @ 100% feed rate (with the above settings it always jams the extruder if you reduce speed)

• Once complete, leave the part to cool until it reaches ambient before removing from build plate (it’ll sure as rain warp if you take it straight off)

Most of the stuff I’m doing at the moment has 2mm thick walls and 100% infill, zero warping unless I have adhesion problems on tricky parts, that’s when I use a brim.

Can't say how the Colourfabb Nylon stacks up against Taulman but I can say the parts are practically indestructible!

Hope this helps

Cheers

Re: Help printing Taulman Alloy 910 nylon (print "tapers")

Just in case someone is still struggling with Taulman Alloy 910 here is my experience:

-> Heat chamber (>35C)

-> Heat bed 90C

-> Regular PEI sheet with glue stick

-> 270C nozzle temp

-> Slow print (~30mm/s max)

-> Print one object at a time avoiding crossing layers

I'm getting nice shiny/sturdy parts. The part sticks to the bed but it tend to warp slightly depending on the geometry.

Just as a hint, don't hesitate to bump up the temp beyond the suggested temps. Sometimes you will get even better results.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Help printing Taulman Alloy 910 nylon (print "tapers")

Hi Nikolia,

That's seriously impressive you can make PEI work. What brand unicorn glue stick are you using?

I've tried Elmers all purpose, watered down PVA and nitro. They all "worked" but not dimensionally stable unless i used a 4+ raft and even then it was hit and miss. The attached has m2 x 3mm locating pins and a bearing and every print has consistent press fit tolerances. FYI clear alloy seems to print more consistently than the pre-colored alloy, plus you can get some cool colors in RIT.

Anyway please let me know, would love to ditch the tufnul. oh and how do i orient these pictures!? Sorry to hijack the thread Martin haha

Re: Help printing Taulman Alloy 910 nylon (print "tapers")

Hi Daniel,

I'm still using the Prusa glue stick. So nothing special or magical. To reduce warping, you need to raise the environment heat and bed heat. But don't expect any magic. If it cools down fast, it will warp. Doesn't matter how strong you first layer bond ist.

In case of dimensional accuracies I do same like ABS. If needed, just drill out holes.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Help printing Taulman Alloy 910 nylon (print "tapers")

Cool might order a stick next time i'm in the prusa shop.

Cheers

Re: Help printing Taulman Alloy 910 nylon (print "tapers")

Hi , I was reading this thread with interest, because I want to try some Taulmn Alloy 910.

I have the Mk3 with the textured powder coated sheet. Can I use that with Alloy 910, what type of glue or separator should I try.

Thanks

Bruce

Re: Help printing Taulman Alloy 910 nylon (print "tapers")

Haven't tried it on a textured sheet because I'm cautious to not damage it. It's hard to get a new one ;). For glue separator any PVA based glue stick should do the job. Just heat up the bed to 90C to get better results. You can also start with just a painter tape and glue stick to see how the filament behaves.

Most important is the environment temperature. If it's under 30C, it will warp doesn't matter what kind of separator you will try. I'm printing at around 40C and still see the tendency to warp.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Help printing Taulman Alloy 910 nylon (print "tapers")

I wouldn't worry about separation 😆

Re: Help printing Taulman Alloy 910 nylon (print "tapers")

Hi Barry,

Honestly start with Taulmans recommended printer settings first http://taulman3d.com/910-features.html

Be cautious with a 90c bed and 270c nozzle with large prints, the Einsy board will be frying eggs in no time at all. Something to consider also are the steppers (specifically the extruder stepper) theyre rated to something like 55c ambient, over that and you risk damage. I haven't had any issues at 50c and have gone through three 1kg rolls and counting.

As for the bed, as Nikolia says, it'll work but it'll warp a little at best, I personally have never been able to get it to stick on PEI. By way of update on the 4mm Tufnul sheet I had been using, recently started using spring steel with a 0.4mm tufnul sheet glued to it. No more clips or custom gcode and I can flex the parts off now. The live Z remains untouched between PEI/Tufnul sheets, although I suspect the .6 nozzle probably allows a little more leeway, would need to pay attention with a 0.4 nozzle.

0.4mm Tufnul - Medium Weave (Whale) https://au.rs-online.com/web/p/solid-plastic-sheets/0374395/

Spring Steel Sheet - https://www.ebay.com.au/itm/Mk3-Mk52-Spring-Steel-Iron-Heated-Sheet-Hot-Bed-Platform-For-Prusa-i3-3D-Printer/263995548038?hash=item3d775c6186:g:tb8AAOSwDOpbyDZi:rk:1:pf:0

Good luck, its worth the hassle imo, the amount of abuse it can take is incredible

Re: Help printing Taulman Alloy 910 nylon (print "tapers")

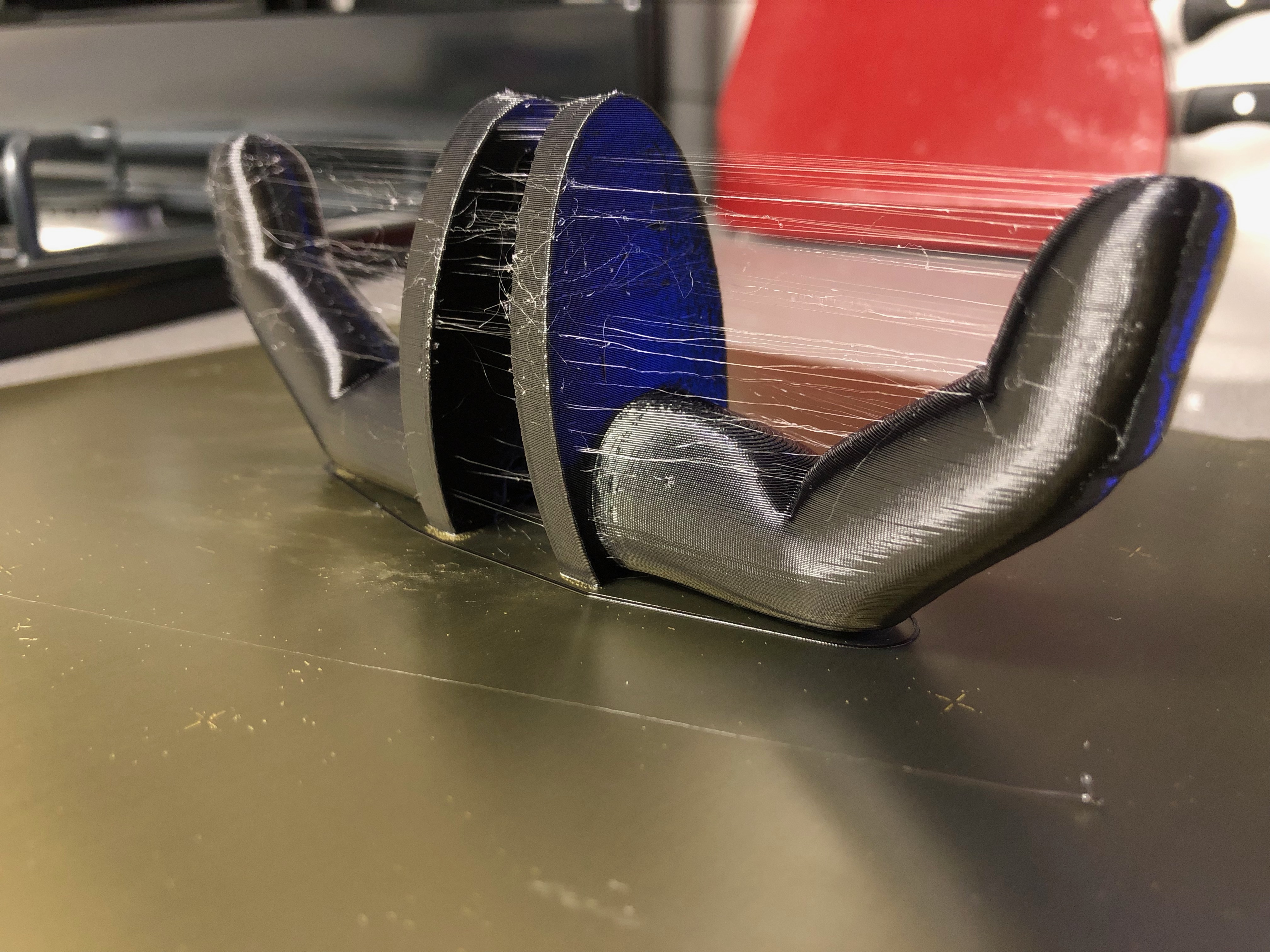

Here is an example print with my settings:

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Help printing Taulman Alloy 910 nylon (print "tapers")

And one more ...

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Help printing Taulman Alloy 910 nylon (print "tapers")

Daniel, What glue did you use between the tufnil and the steel sheet? Did you need a press while glueing?

Thanks

Re: Help printing Taulman Alloy 910 nylon (print "tapers")

Hi Barry,

Araldite super strength, its a slow cure and easy to position. Squashed between two hardback books with trigger clamps.

Its the first attempt, will update if it starts to fail.

Cheers

Re: Help printing Taulman Alloy 910 nylon (print "tapers")

straight nylon can warp a lot, you might consider heating the enclosure.

cf blends are much less susceptible to this. i'm printing colorfabb cf nylon right now with no bed heat at all.

Would you mind to share your setup/settings? I don't manage to print this material.

Thanks!

Re: Help printing Taulman Alloy 910 nylon (print "tapers")

this on my future projects list too

https://www.matterhackers.com/store/c/garolitebuildsurfaces

RE: Help printing Taulman Alloy 910 nylon (print "tapers")

Hi, just saw this thread. If anyone is still reading this here are some comments re printing Taulman Alloy 910 on PEI sheet.

Clean the sheet with Isopropyl alcohol, then lightly sand the surface with 800 grit sandpaper until the whole sheet is matt.

Apply only one wipe of diluted PVA glue. I have had no print separation since doing this. In between prints I wipe the sheet with Isopropyl alcohol and give the sheet another wipe with PVA glue.

Re bed temperature I found the recommended 45 deg C to be best in an unheated enclosure. Higher bed temps resulted in warping.

I only use this sanded side for Nylon filament.

RE: Help printing Taulman Alloy 910 nylon (print "tapers")

Hi Daniel,

Thanks for the advice and links. How did you cut the sheet?

I've just looked at the RS site and they are out of stock till August not really an issue for me.

Cheers

Rick

RE: Help printing Taulman Alloy 910 nylon (print "tapers")

Hi Rick, Hans here.

Don't know if you realise that I print Nylon (Taulman Alloy 910 and ESun Nylon CF) on the original PEI sheet supplied with the printer. No need to purchase any other material.

As per my post above I lightly sanded the clean PEI surface with 800 grit wet and dry sandpaper till matt then wipe the surface with a watered down solution of PVA glue.

Both the Alloy 910 and the ESun CF adhere well to this prepared surface. Small area parts I do print with a brim.

Once there is sufficient PVA glue on the sheet all I do after each print is to spray the sheet with Isopropyl Alcohol and it re spreads the PVA nicely. No need for additional PVA to be applied.

I print the Alloy 910 at advised 45deg C bed temp and the ESun CF at 80deg C bed temp. The 910 shrinks a bit and I scale my parts to 1.007 to compensate. The ESun CF does not shrink at all. It does however squish out in the xy direction by 0.25mm all round which can only be compensated for in the original model. I have my printer set up in an enclosure with some holes near the power supply and on top to prevent overheating. The enclosure does not seem to raise above 32deg C during the print.

Because I do not clean the PVA off the sheet if I turn it over to print other material on the smooth side it sticks a bit on the heat bed. For this reason I purchased a second PEI sheet which I use when printing other material such as PETG.

Hans