Help needed to prevent weird deformations

Hello !

I designed a case for a device and getting a clean printed part seems impossible with this geometry.

Here is a link to download the part if anyone wants to run tests.

It is printed on my MK3S, the printer is just over a year old. All other parts I have been printing come out free of any deformation. Only this geometry is giving me headaches.

Object details:

- part is 5mm thick and has a chamfer all around except on one side

- printed face down because it has few different colors, it is on the outside of the final product and I want to take advantage of the textured buildplate so there is no way I can flip it.

- there is no sign of warping

- 0.4mm nozzle, 0.2mm layers, 3 shells, 4% gyroid infill (increasing infill to 20% did not make a difference), heated bed 60~65°C, nozzle at 205°C, printing with Geeetech Wood PLA (I am encountering the same issue with other brands such as Polymaker and Colorfabb - I tried).

Here are pictures to illustrate the issue:

RE: Help needed to prevent weird deformations

RE: Help needed to prevent weird deformations

There you go, here is the .3mf file panel_side v14

RE: Help needed to prevent weird deformations

I'd reset everything to defaults and try again; your selection of settings is pretty crazy.

RE: Help needed to prevent weird deformations

Alright, I'll try that and report back. But could you elaborate on what makes my settings crazy?

RE: Help needed to prevent weird deformations

@nakwada

It would be easier to ask why you changed each setting. You must have had some reason, right?

RE: Help needed to prevent weird deformations

@tim-2

I would concur with Tim. You have done a shotgun approach to getting this file to print and if you make 1-2 small changes at a time, you will be more likely to figure how correct the problem you have created.

--------------------

Chuck H

3D Printer Review Blog

RE: Help needed to prevent weird deformations

@nakwada

So I got curious - and printed sections of your part ...

The infill settings I thought were messing up, aren't. The object appears to print well with your settings.

Your 4% infill is stretching it. If the part weren't beveled and printed bevel up I'd expect you'd be facing top layer issues - where the first top layers aren't adhering to the perimeters.

========

The frill on your print is most likely related to extrusion factors: too hot, too much material, a nozzle that has damage. Assuming the printer has performed well in the past, the first place I'd look is to ensure the Bondtech gear teeth are clean. Then run a extrusion calibration to make sure everything else in the extruder is working as expected. The top layers in your photos look okay - not great - so I wouldn't expect a major extrusion problem. But even a few percent high can cause material to plow in front of the nozzle. And then there's the nozzle itself: if there's a burr, the nozzle otherwise damaged, it could be dragging material along.

RE: Help needed to prevent weird deformations

@tim-2

with respects to your efforts to printing the OP's file. the infill could still be the issue. at 1000(unlimited length of infill anchor) and the 50mm max your partial files don't cover this possibility sufficiently. while i agree that the 4% infill is really pushing it I think a full size print is the only way to be sure., and to answer your response, nope not this time. it's up to you. but I think your on a good path.

Regards

Swiss_Cheese

The Filament Whisperer

RE: Help needed to prevent weird deformations

Hello @tim-2 and Swiss_Cheese

I reprinted the part after replacing the nozzle and using the default settings from PS 2.3.1

Here is the result, the top surface looks worse even though I switched from 4% to 7% infill (gyroid)

The protruding effect from the borders got better, but is still present on the longer edges.

I'd like to point out that id does not show on smaller sections.

@tim-2, I am sorry, I did not realize my settings were so all over the place. I guess I have been experimenting and forgot about the changes, and it stayed like that. I'm back to clean stock settings now.

Pics for reference

That old nozzle definitely needed to be replaced.

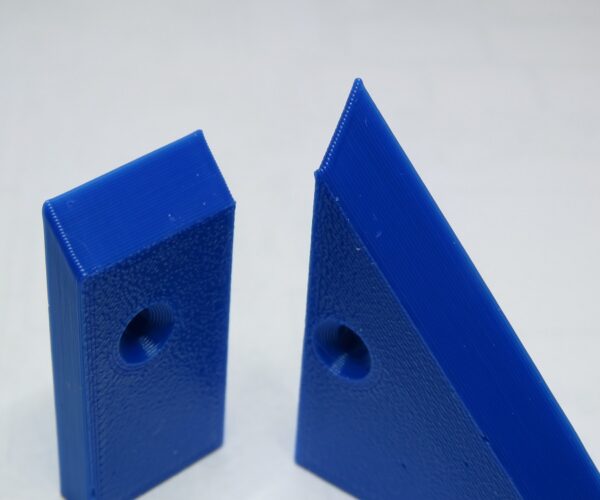

Right : before / Left : printed with new nozzle and after PS reset (dafuq is going on here)

Top : old settings / Bottom : new (deffect is still visible on the bottom left)

Top : old settings / Bottom : new nozzle + reset

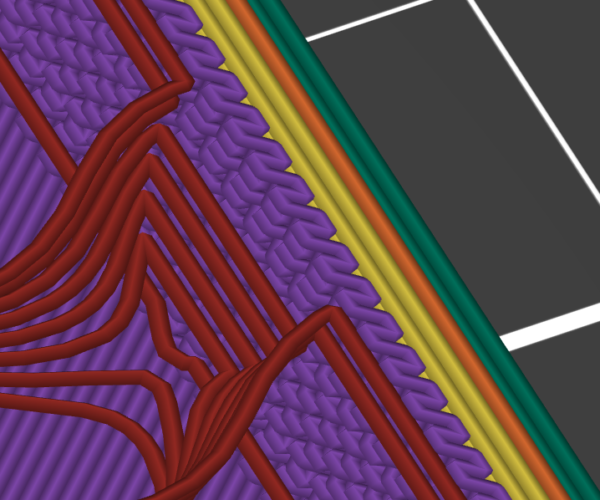

Main difference I spotted in the slice view is the thin purple infill behin the shell. That was not present using my settings.

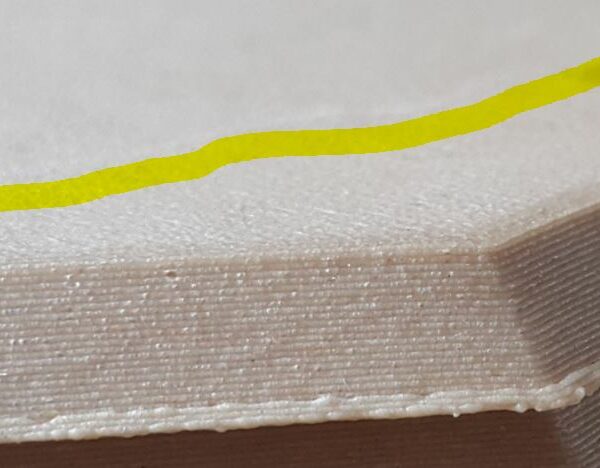

After proper analysis of my machine, I believe I should replace all the printer's rods and bearings.

Even though I keep them lubricated (every 10h of printing or so), I noticed some lines on the rods surface.

RE: Help needed to prevent weird deformations

@nakwada

There's a chance it could be the part lifting - it is hard to keep a full bed print from warp - and they will lift. A symptom my small tests won't show. Try a print with the bed temp cranked high: 75c, maybe even 80c. Let the print progress past layer 1 - maybe to layer 3 or 4, then set the higher bed. Though, it may not hurt much to just set bed temp in slicer to 75c for layers 2+ ...

When a part warps, you'll get layer compressions, which can look a lot like what your are seeing, but generally it's a smaller corner section that lifts, not the entire length and width. Poor overall adhesion may explain it. A good cleaning and higher bed temp to test.

If that white area is real, and you can feel a height difference on the bottom of the part, that is a symptom of a part lifting, too. Maybe it's just that simple.

RE: Help needed to prevent weird deformations

@tim-2

I will run more tests with your suggestion and report back as soon as possible. Thank you!