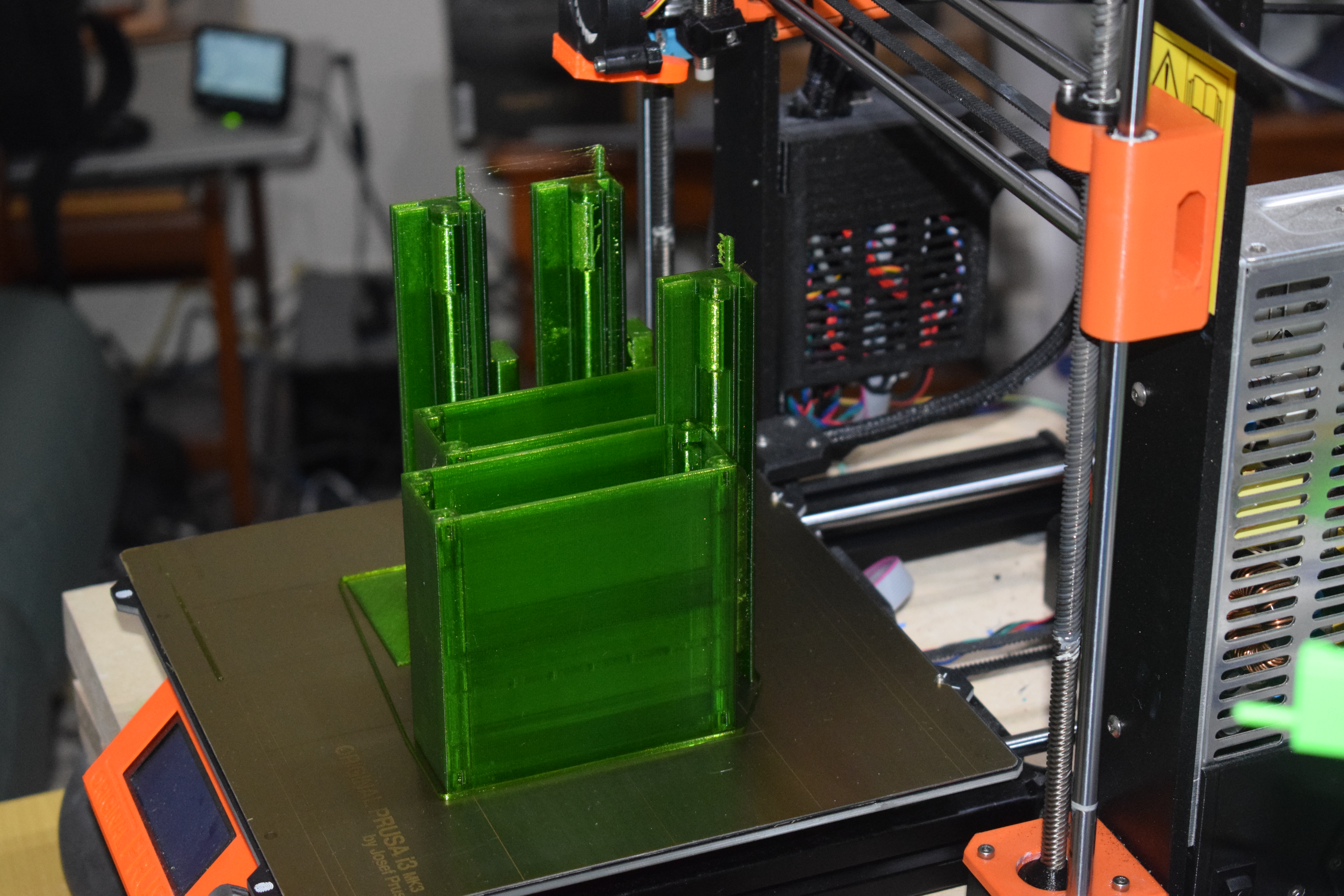

Help improving my prints much appreciated

I print models of composite structural steel beams for work. As you can see, the beam profiles have very thin walls. I am currently using 1mm thin walls on my models, but have tried variations in the 0.9-1.5mm range in the past. I have also tried rotating the beam 90 and 45 degrees on the print bed, to try out both the X and Y axes' ability to draw the long thin walls. In all cases the prints still exhibit some degree of the artifacts/imperfections that you see in the photos . I'm hoping to get some advice on how to get rid of these issues (or at least diminish them) whether that includes altering print settings, or ways to improve the model for easier printing.

I'm printing Hatchbox PLA @ 195C (to reduce stringing). MK3 is on 3.2.1 FW. I am using Slic3r PE 1.39.2 and the '.015 OPTIMAL MK3' as my base profile, but have experimented with other settings. Here are the things I'm looking to improve... Thanks in advance.

1) The tallest thin walls are warping backward as they go up. I've not experienced noticable warping on my other prints before, so I don't know if this is thermal related, or something to do with my print settings...or if I'm being unrealistic that the MK3 can create a perfectly straight 1mm thin wall 2" tall and 8" long? Ambient room temp is 72F/22C, no fans in the room. (Really hoping there is an answer to this other than "get an enclosure", as I don't really have much time to put toward that at the moment.)

2) At both ends of the thin walls (where the extruder is jerking and turning around to go back the other direction), there are artifacts like the ones in the pics. This is an extreme example, most times it happens on far fewer layers. Is this speed related? Do I need to bring the speed down of those direction changes? If so, what setting(s) would I tweak and by how much?

3) The top edge of the thin wall is flared out with a 45 degree overhang. The overhang itself prints well, but on the other side of the wall, it causes a few layers to be very noticeably shifted out. It creates a very defined line down the outside face of the beam. This happens on both the short and tall outside walls of the beam.

Re: Help improving my prints much appreciated

I am currently using 1mm thin walls on my models, but

It is best if the wall thickness is less than 2.25mm to use a thickness that is an exact multiple of 0.45mm.

The image above is only a test print with a 0.2mm layer height with a cheep PLA+ but it does show a consistency with the 1.8mm wall thickness I have used. However it does show up the current inconsistant extrusion problem which is what is causing the ripples in the walls. The final print in PETG with its slower print speeds however came out very good.

The parts in the images above will form part of the printer enclosure I am building, so they are actual structural parts rather than models but I think that is a fair comparison with the part in your images.

I assume from the colour you are printing in the silver PLA that came with our printer. With the current firmware that has problems at around 25mm into a benchy test print. So a different filament may help.

Regards,

Martin

Martin Wolfe

Re: Help improving my prints much appreciated

Martin, thanks for the feedback. As I mentioned, I have experimented with different wall thicknesses over the last few months. I tried using 1.35mm walls (3 x .45), but didn't see considerable improvement. I also tried leaving the walls at 1mm thick, but changing my print settings to .50 extrusion width (so that it would only take 2 passes to form a layer of the wall). That didn't show a notable improvement in my symptoms either. That is why I think there is more than just wall thickness at play here. Likely a combination of many factors and settings? Is print speed a big issue here? Should I be printing slower than the Slic3r PE defaults?

I am actually using Hatchbox Silver PLA, not PRUSA silver. I'm not sure what issues you are referring to with the PRUSA silver, so I'm not sure if the Hatchbox exhibits the same problems or not.

I would welcome anyone else's input on how to improve my issues with these prints. Thanks again!