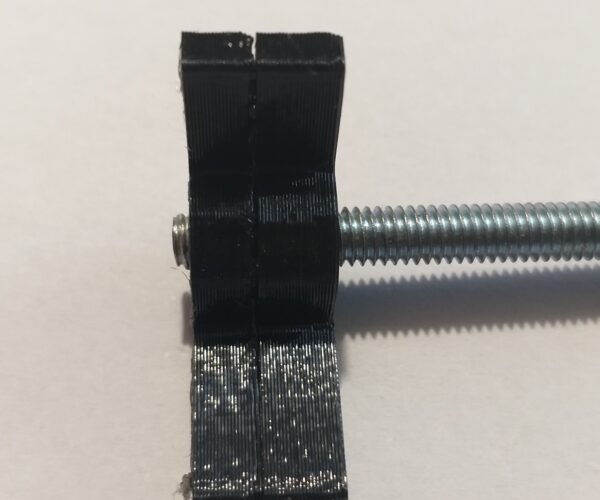

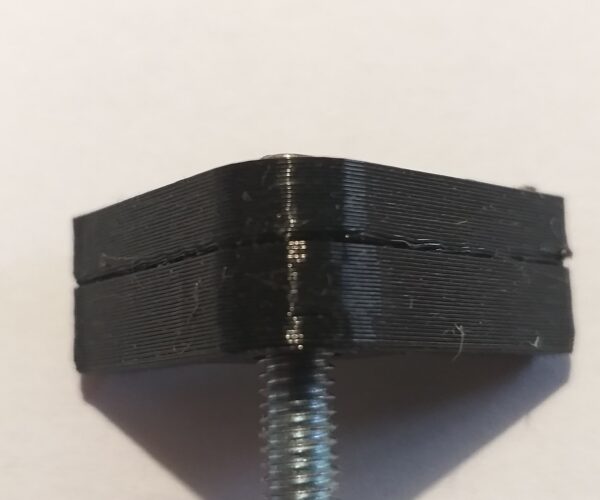

gap beetwin layer after resume print

i everybody, i need to pause printer (M601) and insert nut. after resume print the new layer seem not stick to the previous one or leave sracth along all surface. how can i solve the issue?

Marco

Nutty Problem

HinMarco, are you present when the printer stops and insert the nut immediately?

Or is there a period where the printer stands idle whilst waiting for you to place the nut?

I am wondering if there is a delay, does the bulk of the previously printed plastic, have time to cool and shrink away from the print head?

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

hi Joan,

i'm watching all the process and insert the nuts immediately but the nozzle starts anyway to cool down . i don't remember is the nozzle reach the target temperature when the printing start. i will check

thank you

Marco

Try a color change instead of a pause

The color change loop will make sure the nozzle is at the right temp for the print before it lets you load the new color. You could try using the color change cycle instead of simple "pause/resume" so that the nozzle temp is where it needs to be when the print resumes. you'll have to go through an extra eject filament/load filament step, but it will even have an additional advantage - the nozzle moves back to exactly the right place and the extruder body will not be near the print.

RE: change color routine works fine!!

Dan thank your for the hint. 👍 works perfectly!!!

as suggest by Joan i checked the temperature when the printer restart, so i reliazed that the nozzle dosn't reached the target temp when the printer was resumed. so, i added M109 s240 command after the M601 but the gap was still there. i susppect wasn't temperature issue but an under extrusion on the first layer printed after pause. i'd like to examine the gcode to see wich command are used on change color cycle.

Marco

if the extruder is below 170c when it tries to print, the firmware will prevent extrusion, but XYZ moves can occur...

https://marlinfw.org/docs/gcode/M302.html

M302 controls the low temperature extrusion performance

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK