Fuzzy webby prints

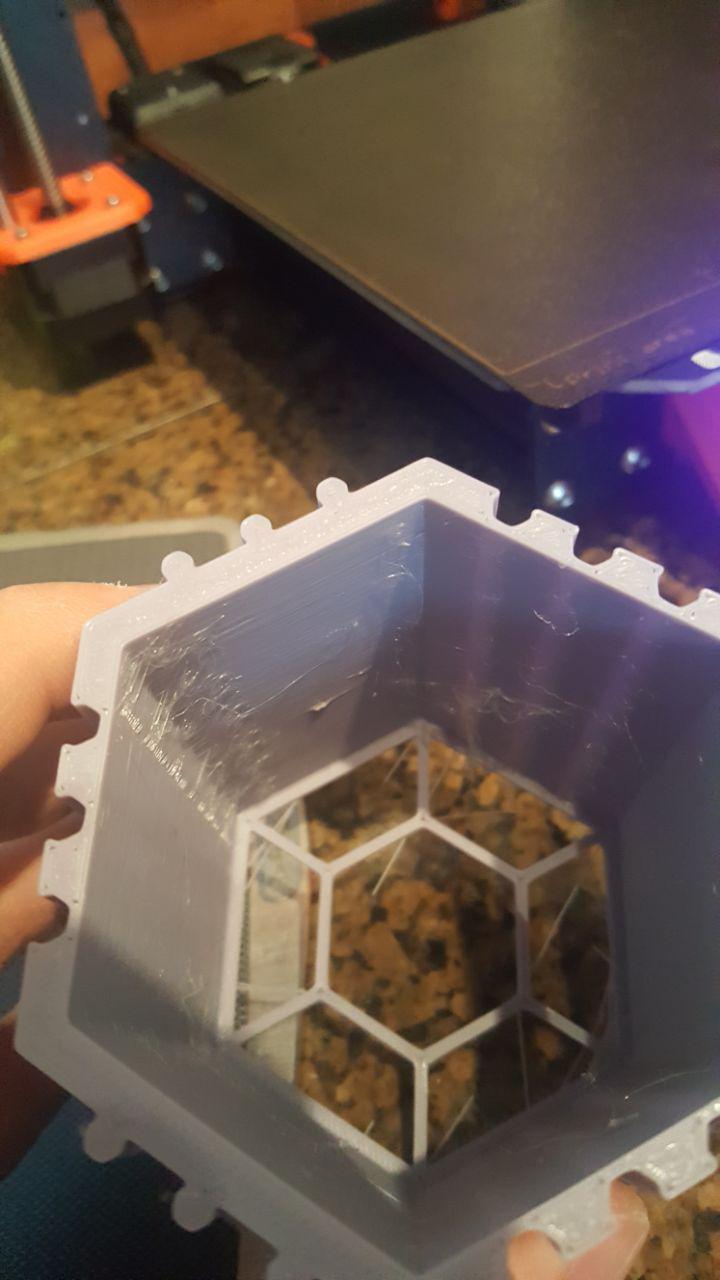

I've been running into issues printing ever since I tried using wood filament and things got clogged and I tried cleaning the nozzle out with the acupuncture needle. I originally thought maybe it was the PLA+ filament I was using, but then I tried other filament and am still having issues. My printer didn't used to print like this but now it does and I'm not completely sure where to even start. I tried replacing my nozzle with a hardened steel nozzle but I am still having issues. As you can see the prints are pretty messy. Structurally they come out ok, but its not clean. I've also noticed some very fine webbing building up on the cables on the extruder as well. Any ideas what might be going on? I've tried messing with retraction amount and retraction speed, and while it helps it doesn't quite seem to be solving the issue. I'm wondering if maybe the PTFE tube is damaged from the acupuncture needle? What kind of symptoms would that cause? Any ideas would be super appreciated. Thank you!

Everett

Re: Fuzzy webby prints

Welcome to FDM and cheap filament.

A couple of things: do you have a new nozzle? What does the part look like when using a different brand?

Wood leaves gunk that can plug. Running a needle up the nozzle only moves a plug around: only a cold pull gets gunk out of a nozzle. In the worst cases, the needle damages the nozzle and orifice so that they are no longer true and round. Non-round nozzle don't pull the filament uniformly and the filament no longer cleanly separates from the part.

Inexpensive filament can also have stringy characteristics. An easy test is to try a different filament. If stringing goes away - you know the 'desired' filament will require slicer tweaks to print well. If stringing persists, swap the nozzle.

ps: if you have ever changed the nozzle, did you follow E3D's and Prusa's instructions? A misinstalled nozzle can also cause all sorts of odd effects.

Re: Fuzzy webby prints

Do you have a recommendation on a good filament to purchase from amazon? I'm currently printing with inland purchased from my local Microcenter, but I didn't have issues with inland prints in the past.

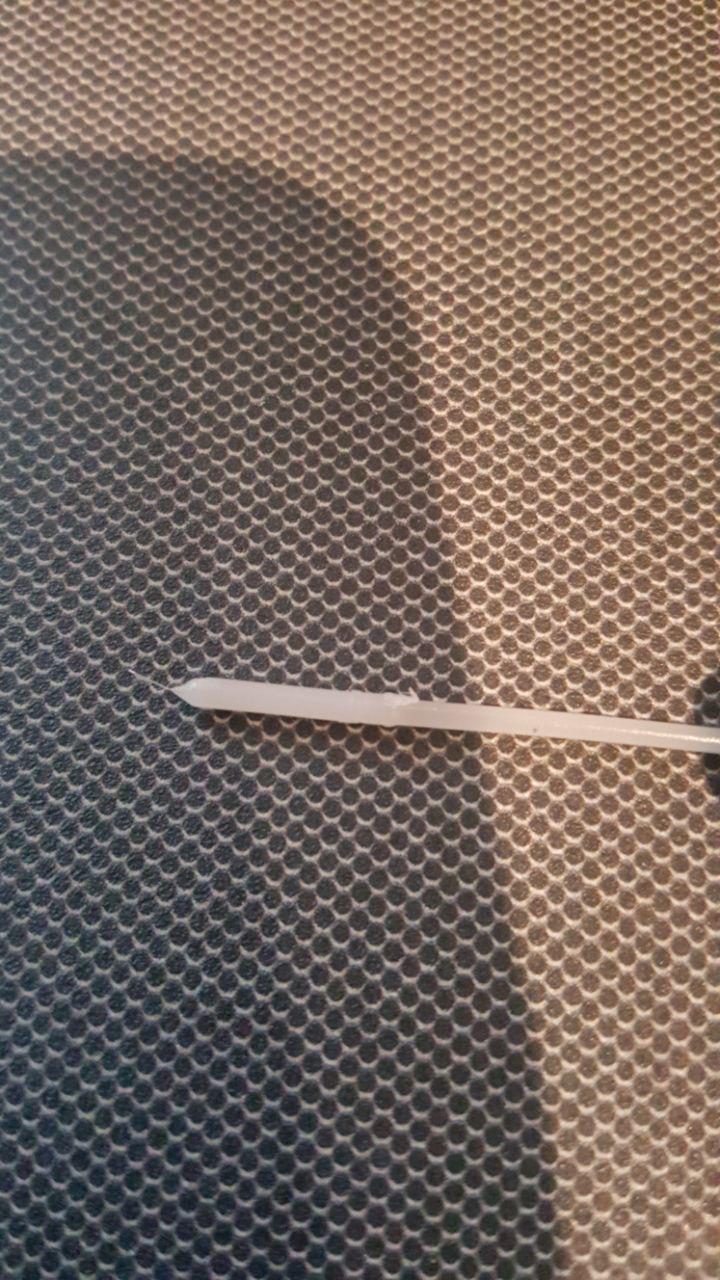

Regarding the nozzle, I tried printing with wood filament with the original nozzle, that got gunked up pretty badly, and started printing like what I'm seeing now. I thought it may have been the nozzle got damaged, so I bought a hardened steel nozzle and I believe I installed it correctly (I followed the video as closely as I could) but I am still seeing the same print issues. I just did a clean pull and attached an image of the pull. I did the pull again but it was a bit smoother. Going to try another print tonight and see if I see any difference in print quality.

Re: Fuzzy webby prints

A few tips, wood fill in my experience likes a bit cooler temps than regular PLA, it keeps the wood particles from charring and becoming a gunked up mess in your nozzle. So that's for wood fill, for the nozzle some reports state that hardened steel can require higher temperatures than normal since it is not as efficient as brass, but I have printed at standard profiles with (mostly) no issue.

The general wisdom for stringing is retraction and temperature, easy fixes can be to adjust your idler tension (on the extruder) or to lower your print temperature. Sometimes you will get a roll of filament that has a mind of its own, it was like that for me with the roll I got with my printer. I do get wispy strings like you do still myself, however they don't ever ruin my prints, and I carefully and quickly blast them with a heat gun to shrink them for easy removal. This is not to say you need to give up, just that it is not the end of the world. On the other-hand your printer should not be a spider spinning webs either.

I have used Hatchbox PLA to pretty good result personally, their Silk line is a bit touchy but the standard PLA hasnt done me wrong.

I am still relatively new myself, but I would try temperature and tension, try and grab a stringing test file from Thingiverse and post your results, it will help you dial it all in.

Re: Fuzzy webby prints

Nothing wrong with the pull - looks clean. And since you've replaced the nozzle with steel, the needle shouldn't be doing much if any damage.

As stated above, stringing is one of those things you can choose to fight by detailed tuning for that specific filament; or you can simply shrug and pull out the heat gun. A heat gun is okay for high bulk parts like your model; but not great when the model has spires or fine details that melt as quickly as the spider webs.

A quick fix for stringing is to drop nozzle temps. It may be a bit risky when using a steel nozzle, but since you are stringing quite a lot, the filament might print well enough: you can print a small part and make sure layer adhesion and surface quality is still good. Increasing retraction is also a method that will work with some filaments. Retraction comes with some complexity - how far to retract, how much z-lift is also needed, does the end trace swirl need to change, etc.

As for filament quality: I was half joking about cheap filament. When hooked on 3D printing, you buy what you can afford: some of my favorite cost me just over $12 a kilo. That said, the cheap filament sometimes comes with problems: more prone to stringing, more variance in diameter, colors can shift in a spool. And sometimes the cheaper filaments are just slow moving lots of good filament (color match problem, unpopular odd color). I have tried several brands from Amazon. Only one I probably won't buy again. Printing the cheapest the past couple days - 3D Solutech - and it's been fairly good. Paramount is another brand that has a good color selection on their factory site, but variable selection on Amazon. Tianse has some pretty good wood fills - but they take effort to print well (carving on a print is pretty cool). But another color of the same Tianse brand wasn't as good and had diameter issues. Amolen was a bit more expensive - but I haven't noticed any better quality over the other brands. And latest Zi-Rui branded filament acts a lot like the Paramount and Tianse (same spool markings, too). Tried a couple other brands, too. All seem to share the same common theme: you never know what it is until it's a finished print. Same holds for Prusa and Prusament.

You also seem to be getting a lot of "drippage" ... is the HEX on your nozzle seated firmly against the heater block? Or does it look like this - where the HEX is clear of the heater block?

Re: Fuzzy webby prints

Another suggestion to add to the list:

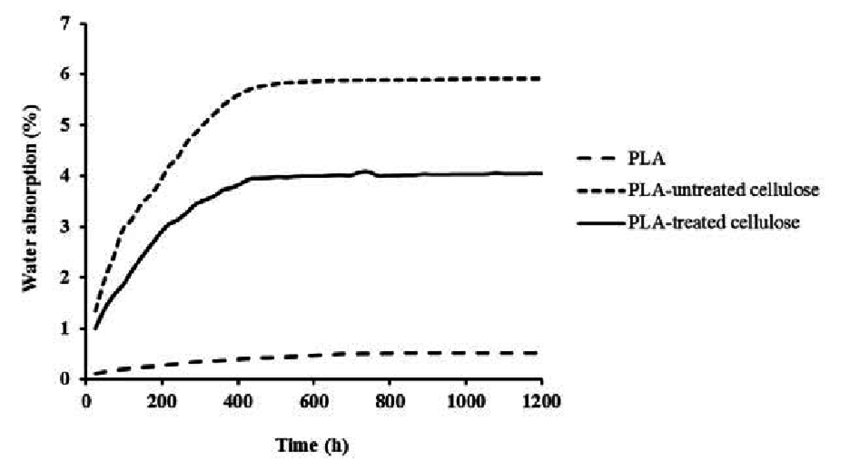

Humidity in the filament... What is your humidity situation? coastal? High general humidity? filament left out and not sealed up?

I live in a very humid area and will get hairs and strings like that after my filament has been out and used for a day. If I have a 10 - 12 hr print session, I have to dry the filament in a dryer before the prints will stop stringing. PETG is very bad, but PLA will do it as well... Drying resolves the problem.

If you are in a very arid climate, like New Mexico or Nevada or somewhere like that, then it is less likely, but anywhere it could have higher general humidity it is something to check...

Strange women, laying in ponds, distributing swords, is hardly a basis for a system of governance!

Re: Fuzzy webby prints

I live in a very humid area and will get hairs and strings like that after my filament has been out and used for a day. If I have a 10 - 12 hr print session, I have to dry the filament in a dryer before the prints will stop stringing. PETG is very bad, but PLA will do it as well... Drying resolves the problem.

Wow - Nylon takes a while to absorb significant moisture unless in 100% condensing humidity or warm water (then it's days before saturation); PLA longer.

RE: Fuzzy webby prints

Yeah, humidity is very high here at all times, it rains every couple of days and the inside humidity almost never goes below 60% on three different humidity indicators... I do no wonder if there is a leak in the roof making it wet in the ceiling in the room where my printer its all the time... I do not own it, so it is not something I worry about long term. I just keep my filament in containers with desiccant and dry in a $30 filament dryer which works.

I do notice the change between dry filament and non dry filament with regard to stringing and small wispy hairs on the prints, so I offered it as a quick and low effort test.

Strange women, laying in ponds, distributing swords, is hardly a basis for a system of governance!

RE: Fuzzy webby prints

Thanks for the replies! I increased retraction slightly to 1.2mm from 0.8 (default) and while it seemed to have helped a bit, it still seems off. I went ahead and printed a benchy at 0.05mm and pretty unhappy with the print quality. My prints used to be perfect, and now I'm getting this 🙁 I don't think its humidity as this has been on a couple different filaments and I'm in Colorado and while my house has a whole house humidifier it doesn't get too humid here (35%). Increasing print temps seemed to also lower stringing slightly. I've included a pic of my nozzle as well. The nozzle felt tightened all the way, I included a pic.

I have a few questions:

- What symptoms can you expect if your ptfe tube needs to be replaced?

- What kind of symptoms would you get with bent rods?

- How about loose belts?

- bad bearings?

I'm debating on picking up the mk3s kit since I feel like there is something wrong with the extruder and will need to do a rebuild, but I really don't want to wait the 10 week backorder.

Thanks again, and if there are any questions I can answer to help track this down I'd greatly appreciate it.

RE: Fuzzy webby prints

The z-lifts look like there is no swiping happening. If not using Slic3r PE, what do prints look like if you do slice with Slic3r?

For the most part, I find reducing temps help more with stringing that going higher. But stringing is filament dependent, and different brands are picky to all sorts of settings. Many - including me - rather than trying to dial in settings for a single filament just use a heat gun to clean up spider webs.

Probably not doing anything for stringing, but your nozzle looks like it is too far in - this can cause problems with the Prusa heat break and filament leaks out the top of the heater block. E3D has a good nozzle swap procedure (sorry, no link). The HEX of the nozzle should be well away from the heater block as shown here.

RE: Fuzzy webby prints

Thanks! I checked the nozzle, it definitely isn't overtightened, and I imagine I don't want it to be loose? I do want to say that I was having these issues with the original nozzle was well (this all started ever since I tried the wood filament, things got clogged and I tried unclogging it with the acupuncture needle, and I worry maybe I was too aggressive in trying to unclog it?). I'm somewhat debating on buying a replacement assembled extruder from prusa to see if that makes a difference. Regarding the z-lifts, I am using Slic3r for these prints, and almost all settings except retraction are default minus the filament settings. I know it wont help with stringing but I did try tightening my belts, and I think it helped a bit. I will have to try printing another benchy at 0.05 again to see how it compares. The most frustrating aspect of this is that I know it can print better, I just don't know where to begin, but in a way, I suppose that's part of the challenge as well.

RE: Fuzzy webby prints

The nozzle must be tight - but against the heat break, not the heater block. If the HEX is bottomed out, the nozzle can't be in good contact with the heat break. This snip shows what looks like filament oozing out the top of the heater block, an indication the nozzle is not properly installed. The nozzle is screwed in fully, then unscrewed 1 full turn, then the heat break is installed until it contacts the nozzle. Then, heat up to 280c and tighten to 3nm.

RE: Fuzzy webby prints

Thanks for the reply! I know that looks like oozing filament but that is leftover gunk from a bad print that globbed all over the extruder (I've cleaned it since) I wasn't completely following you, but I just watched this (and now that I'm looking at your post again I just realized you included a link to the v6 assembly... completely missed that weblink the first read through) and now I get what you are saying! I did notice that my heater block could rotate fairly easily in the extruder mount so I'm guessing the nozzle is not butting up against the heat break. I will try taking things apart tonight/this weekend and see what might be going on there. On the brightside of all of this, I am definitely becoming less paranoid about taking my printer apart and putting it back together! Thank you again for all your help, I'll let you know how it goes.

RE: Fuzzy webby prints

If you are careful, you can pop off the extruder fan, pull the nozzle loose that 1 full turn, then spin the heat sink to drive the heat break down into the heater block to contact the nozzle finger tight. Replace the fan, heat and torque nozzle to 3 nm.

The Tom's video misses the thermal paste on the heat break / heat sink threads - it's a hard requirement.

RE: Fuzzy webby prints

Ok, I went ahead and took my extruder apart and cleaned each part, and noticed the PTFE tube that butts against the heatbreak wasn't a completely clean cut so I went ahead and cut it, and I put everything back together. The nozzle does stick out slightly more now when tightened up, and while the prints seem slightly less webby, it's not quite as honed as I think it can be, but I'm wondering what the odds are of me having multiple low quality filaments are (I suppose it's unlikely but I suppose its possible?), so I will try buying a new roll soon from a different vendor. I've attached a some side by side prints of two benchies. The left print is prior to cleaning the extruder, and the right is post cleaning. To be fair, the left print has retraction set to a custom higher amount than the right which used the slic3r's default 0.8mm retraction.

On a side note I did notice that the tightened belts did seem to help quite a bit with the print quality at 0.05mm (compared to the gray benchie).

Any additional thoughts on what I can tune to reduce webbing? I suppose the meantime I will try out a separate roll from a different brand. Do you know if poorly calibrated extruder steps can cause this issue?

Thanks again!

RE: Fuzzy webby prints

I debated on creating a new thread, but I decided this has a bit of history to me trying to sort out some of my print issues. So another issue is that I would occasionally get loose ends on my prints, but I seem to be getting it a bit more frequently and I'm not completely sure what's going on? I just upgraded to the latest firmware and prusaslicer. Any thoughts on what's going on here? It all seems retraction related but I don't know what else I can change. Some things I've done recently is calibrated PID, calibrated temperatures, calibrated extruder using these steps https://www.instructables.com/id/How-to-calibrate-the-Extruder-on-your-3d-Printer/

Thanks again!

RE: Fuzzy webby prints

Supports in Slicer are less than perfect. Any time you see a support that is only one unit square, do something before trying to print. I'll change support angle as needed to 1) get better support coverage/density 2) eliminate single support towers; etc.

The filament pieces you are seeing come from places where the nozzle no longer extrudes onto a support: where the support has drifted, or failed. See image zoom.

So the extruder extrudes a 2 mm of trace, it isn't catching anything, so when the extruder moves to the next point, this finger goes along and attaches to the next low spot on the part - essentially gets wiped off as the nozzle travels.

The lightsaber is failing because of unsupported overhangs. Use the preview after exporting gcode and look for the "unsupported" traces.

RE: Fuzzy webby prints

Back to the webs ... are the last Benchy print straight from the Prusa gcode, or did you slice them? Normally, Benchy turns out pretty well with no fuss needed.

The basics are to run a PID calibration for the nozzle heater. Ensures the electronics are mapping power correctly. Also make sure - if you are trying to slice - you have the default Print & Printer settings, 0.15 mm Quality, Prusa PLA filament or generic PLA filament profile selected, and don't change any of the presets. Benchy should print without any tweaks.

RE: Fuzzy webby prints

Thanks for all your input Tim. The Benchy prints were all my own slices at 0.05mm. I did the gcode included in the prusa software install and it turned out well, some very minor stringing but nothing that bothered me, but I would say it was on par with my own slices at 0.15. And thank you regarding the supports. Maybe I'm just starting to print more complex stuff and noticing some more issues as I play around with my settings.

Thanks!