RE: First layer height 0.6mm nozzle

I'm trying to find a good opaque black Petg I can ideally buy on Amazon UK.

If only Prusament was available this way. Unfortunately Prusa use Hermes for delivery so those idiots will just throw the reel over the fence straight onto concrete.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: First layer height 0.6mm nozzle

@chocki

Should be ok if it's in a box lol

RE: First layer height 0.6mm nozzle

@bobstro

The thinnest first layer with a smooth surface that I can achieve is at 0.23mm. If live-Z is pushed any lower then the surface finish starts getting rough and subsequently thickening the layer. I did a lot of experimenting over the weekend and the only way I was able to push live-Z low enough to get a layer that measured 0.2mm was by bringing extrusion factor way down to 0.85. An extrusion factor of 1.03 is required to get 0.7mm walls with this nozzle.

A thought I had is, maybe the infill overlap is limiting the first layer height since the larger nozzle can't print as thinly as a 0.4mm nozzle. I put this theory to the test by printing a first layer with zero infill overlap but still couldn't get below 0.23mm. What do you think? Did you get a chance to test the first layer on your machine?

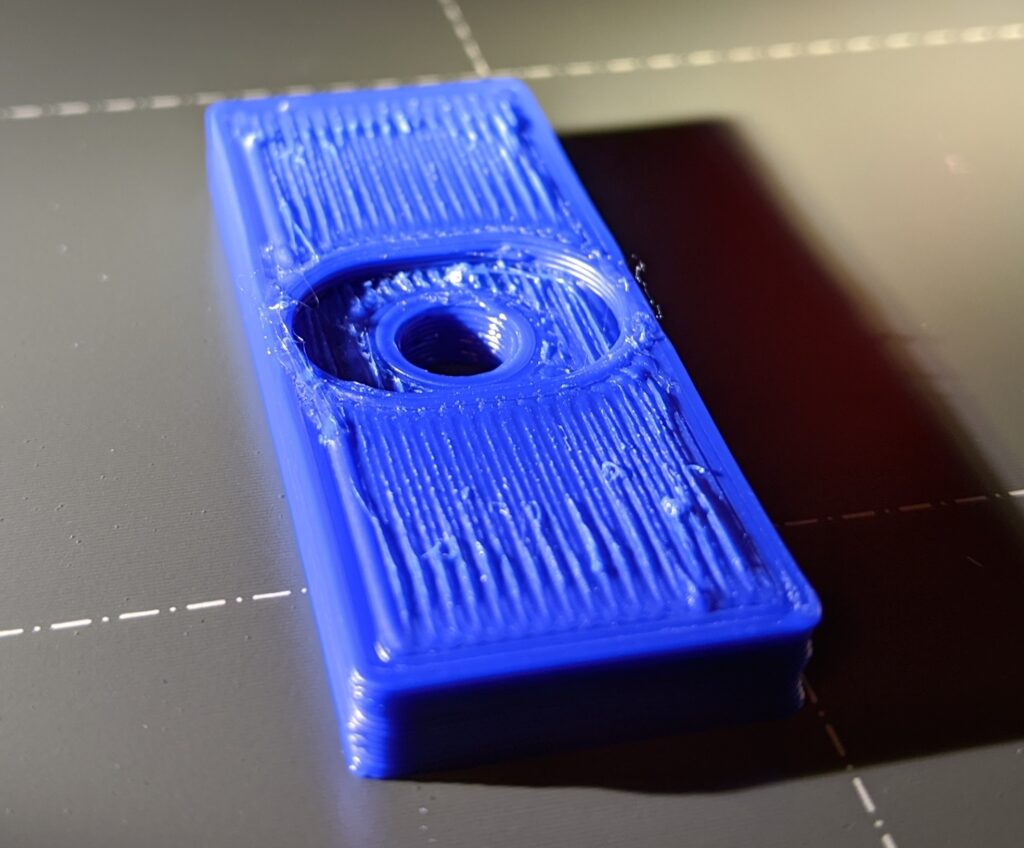

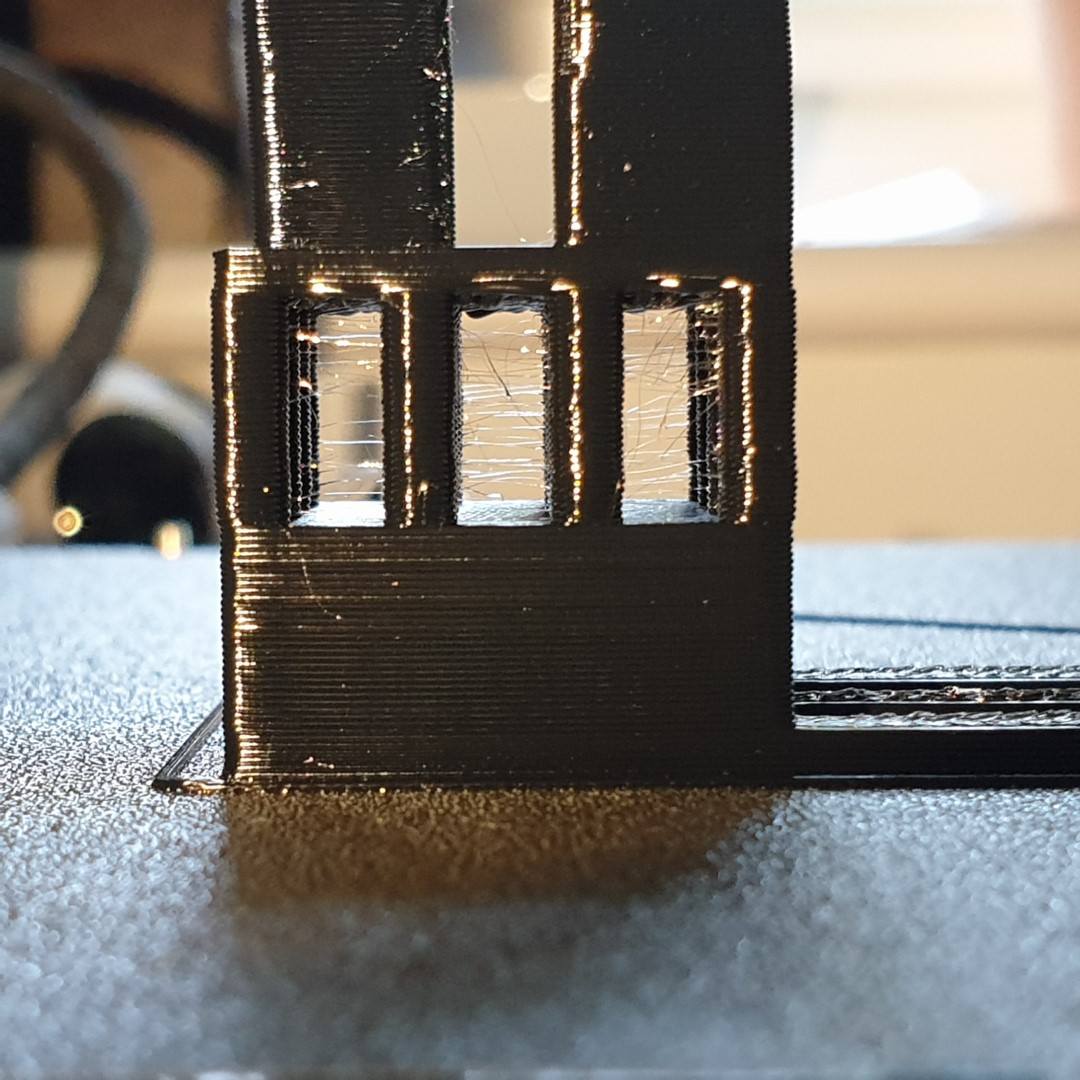

The first layer thing I can get past since I'm able to achieve a nice, smooth 0.23mm first layer that adheres superbly. What I can't settle for is this top layer quality (see pic below). Those ridges are super rough. My top solid infill speed is reasonable at 41 mm/s. Somebody suggested that retraction speed/distance can cause rough ridges in top layers. Do you think it's worth investigating this? It sounds like others don't have this issue though.

RE: First layer height 0.6mm nozzle

[...] The thinnest first layer with a smooth surface that I can achieve is at 0.23mm.

Just to confirm: We're talking about 3/100 of a mm. Is that a critical deviation? I tend to get caught up in "precision" only to finally realize I'm after numbers that would have been unthinkable a few years ago. If the overall size of the part matters, it might be better to measure the final dimensions.

If live-Z is pushed any lower then the surface finish starts getting rough and subsequently thickening the layer. I did a lot of experimenting over the weekend and the only way I was able to push live-Z low enough to get a layer that measured 0.2mm was by bringing extrusion factor way down to 0.85. An extrusion factor of 1.03 is required to get 0.7mm walls with this nozzle.

My printer is tied up at the moment. I'm doing a full-plate print with a 0.6mm nozzle. Unfortunately, I'm using a textured sheet, so that may throw off the measurements.

I do have a First Layer calibration print I did with PLA on the smooth PEI surface with a 0.4mm nozzle. I measured it at several points -- keenly aware that my cheap calipers only boast a 0.02mm accuracy -- and found a lot of mid-print measurements ranged from 0.2 to 0.22mm, with some at 0.23mm. Part of the problem measuring like that (with my tool at hand) is that I'm measuring the worst case of several extrusions which can vary. Not to mention that a bit more or less thumb pressure can move the measurement up or down 0.02mm easily. If I restrict my measurements to the edges where inter-extrusion distortion is minimal -- mainly the long edge perimeter extrusions -- I'm getting consistently closer to 0.2mm. At the very center, the edge extrusions are measuring closer to 0.17mm, indicating that the extrusion rate is not even when the nozzle accelerates. That's something tuning Linear Advance might help with.

A thought I had is, maybe the infill overlap is limiting the first layer height since the larger nozzle can't print as thinly as a 0.4mm nozzle. I put this theory to the test by printing a first layer with zero infill overlap but still couldn't get below 0.23mm. What do you think? Did you get a chance to test the first layer on your machine?

Still in progress. I do expect a 0.6mm nozzle to be a bit trickier mainly since the overlap between adjacent layer tends to produce more dramatic ridges.

The first layer thing I can get past since I'm able to achieve a nice, smooth 0.23mm first layer that adheres superbly. What I can't settle for is this top layer quality (see pic below). Those ridges are super rough. My top solid infill speed is reasonable at 41 mm/s. Somebody suggested that retraction speed/distance can cause rough ridges in top layers. Do you think it's worth investigating this? It sounds like others don't have this issue though.

Ah, now that is something else. I'd be less worried about the 1st layer since your adhesion is good. That really looks like over-extrusion. Have you tried a different top fill pattern? I see you're using a top infill width of 0.6mm, which is good as smaller usually yields a smoother finish.

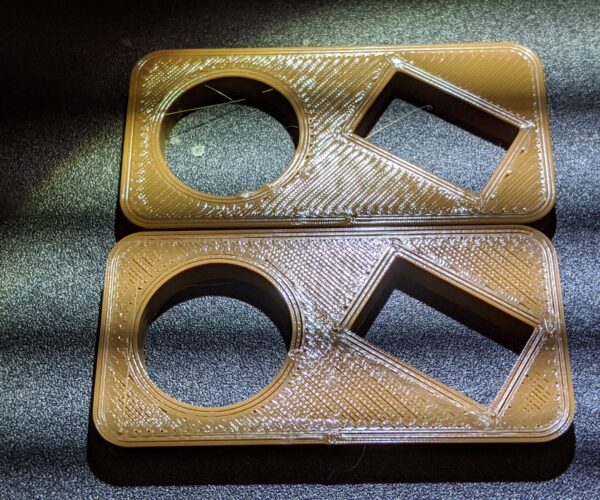

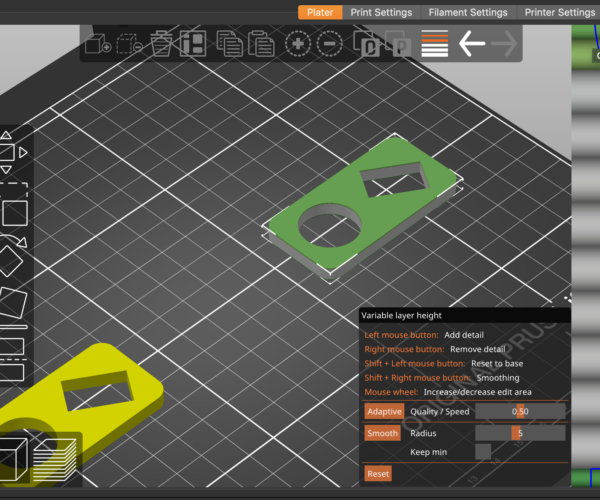

You're using a 0.4mm layer height. You might try enabling the variable layer height for the part and use a thinner layer height at the top. This picture isn't great, but you can see the difference using PrusaSlicer defaults (top-right) and a thinner top layer (bottom-right):

As for your wall widths: Another conversation today reminded me that Slic3r (on which PrusaSlicer was originally based) doesn't use straightforward calculations for perimeter extrusion widths. Adjacent perimeters overlap by roughly 0.03mm at 0.2mm layer heights. Calculating "perfect" extrusion widths is going to be annoying with thin walls.

I've got the 0.6mm nozzle mounted and will try a few things once the printer is free. I'm more interested in the top surfaces you're getting.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: First layer height 0.6mm nozzle

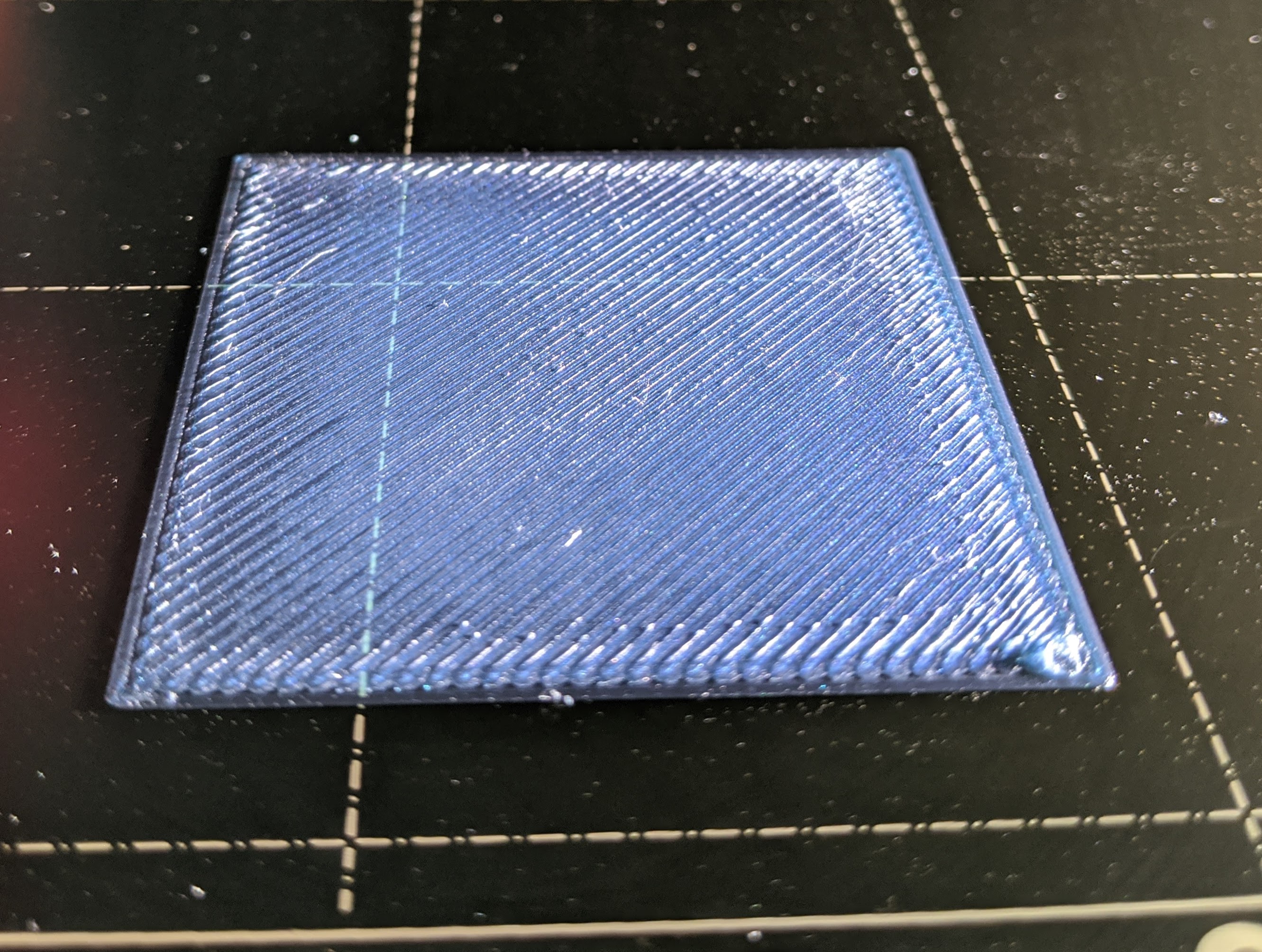

Uhm... did not expect this. I just printed your 3MF with your filament settings directly...

So ... maybe you just need less precise calipers? I'm at a bit of a loss. That's better than I usually get!

I'm printing with RePLAy 3D recycled PLA, so hardly precise stuff. There are some variations, but most measurements are coming out very close.

Dialing Live Z down (more negative) 0.03 screws up your 1st layers, correct?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: First layer height 0.6mm nozzle

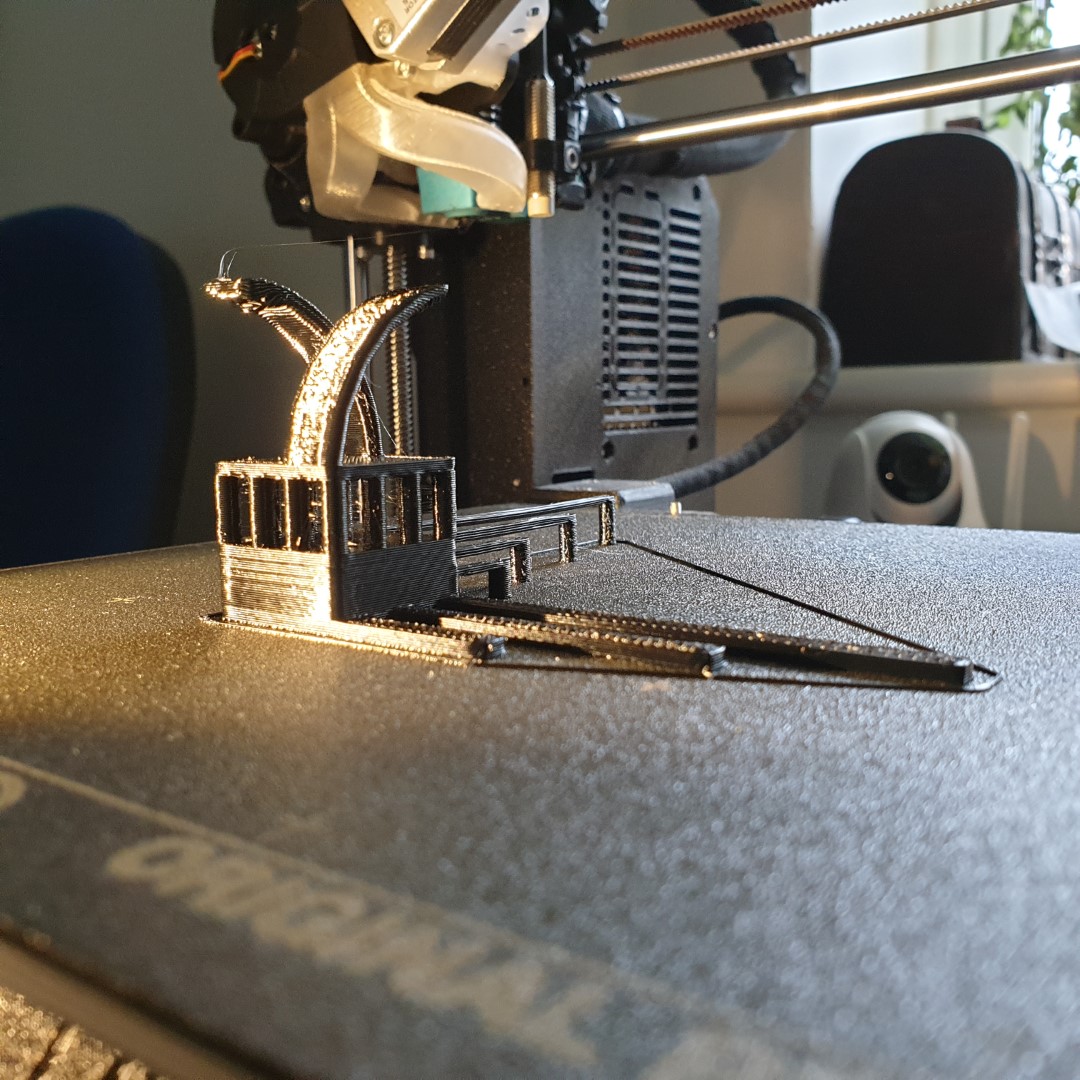

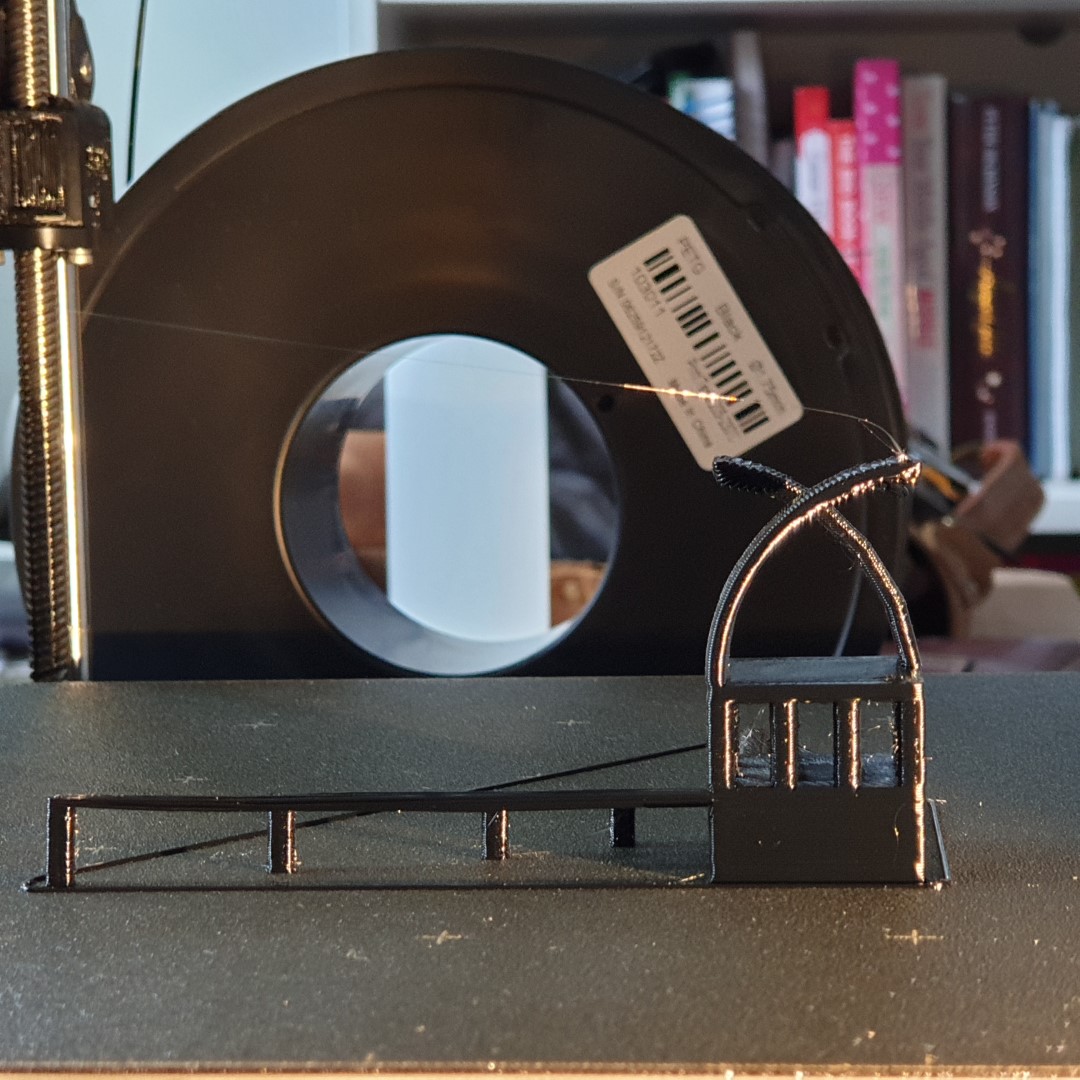

Just wanted to show a quick comparison. Top piece is printed with 0.48mm layers using a 0.60mm nozzle. Bottom is the same but using adaptive layers near the top to print layers down to 0.15-0.2mm (it's not precise). The lower layers are under-extruding a bit. It's always hard to pick out in a picture, but the finer layers produce a smoother finish:

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: First layer height 0.6mm nozzle

@bobstro

Can you send this STL and I'll print to compare?

I was able to get the first layer barely down to 0.21, with some spots reading 0.22.

RE: First layer height 0.6mm nozzle

@bobstro

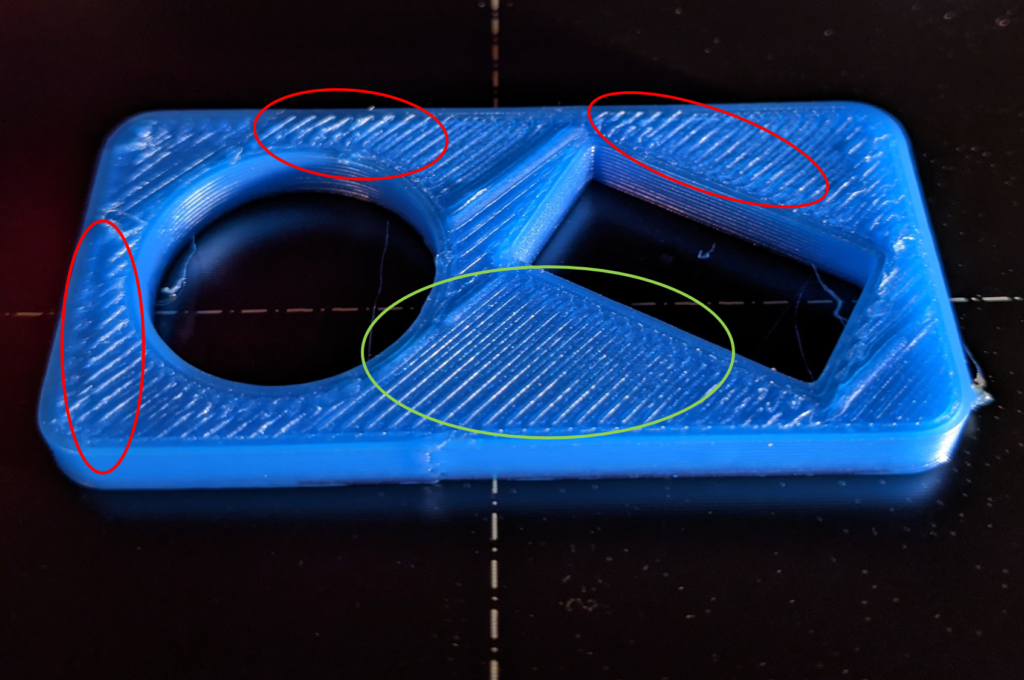

The top layer issue seems to be happening at either the start or end of lines close to perimeters. You can see in the first layer picture below that there's a border of raised filament next to the perimeter, and then weirdly a fairly large area in the upper right. What could be causing the rough border?

RE: First layer height 0.6mm nozzle

[...] The red circles are rough, raised extrusions which consist mostly of shorter lines than the green region which is perfectly smooth. Why might these shorter extrusions be rougher?

What filament are you using? Have you calibrated the Linear Advance setting? That can help even out filament flow at the start and end of moves.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: First layer height 0.6mm nozzle

@bobstro

Filament is Prusament PLA.

Top layers with a 0.4mm nozzle are perfectly smooth at linear advance K28. Couldn't ask for better honestly.

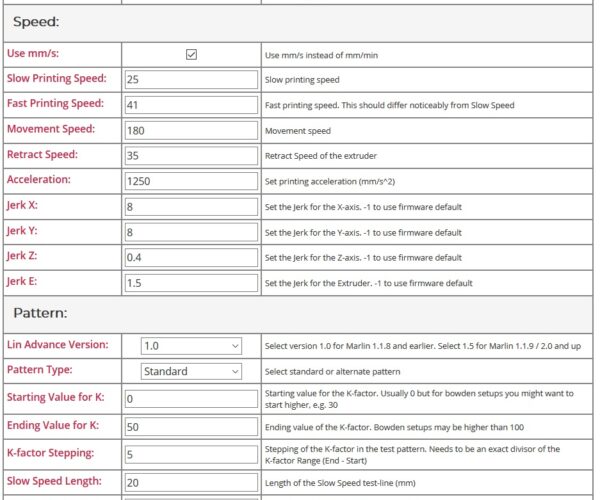

For the 0.6mm nozzle I used the Marlin linear advance calibration tool with the parameters in pic below and got the most consistent line width at K14. I just printed two more of the same object, one with K28 and another with K36 just to see the effects but there wasn't much difference.

Anything else that might be affecting these shorter extrusions?

RE: First layer height 0.6mm nozzle

Bought some SUNLU Black PETG the other day since it is quite opaque which most PETG filaments are not, still getting my 0.6 mm nozzle settings right plus temperatures since I replaced my heater block with Nickel Plated Copper and a PT100 upgrade with an accurately calibrated nozzle temperature.

This is my first torture test, Nozzle temp 215 (Quite low for a PETG, but this is a blend of some sorts), cooling min 18, max 30, low to get better layer adhesion, but will have a detrimental effect on overhangs as you will see below. Bridging flow rate 0.8 and only 20 mm/s.

The infill is actually 5% concentric, this in effect creates a 3rd perimeter which supports a bridging layer and leaves the rest of the inside completely hollow, you should really check it out using the layer previewer how the bridging layer is fully supported, whereas most other fills print part of the bridge into thin air which then leaves a less than ideal top surface, you can see how flat the layer is in the third picture as it is fully supported by bridging across the whole section of print.

I can improve the overhang by increasing cooling, but this reduces layer adhesion, but I think it's not too bad for a quick setup and test, and for now is good enough to get on with printing, I'll tweak things a bit more when time allows.

Oh, and no buildup of filament on the nozzle at all, but this was only a 45 minute print, but still a good result for initial settings on a new filament for me. Note: This PETG ends up printed quite flexible compared to what I was using just before which was RigidInk PETG and strings a lot more, hence the 215 Deg, but it seems to print quite well at this and I think I can afford to either drop the temperature a little or increase the cooling to improve printing, but will need to test further as inter layer strength will reduce.

Link to torture test: https://www.prusaprinters.org/prints/6179-single-filament-torture-test

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: First layer height 0.6mm nozzle

I'm playing around with various settings and slicers. It's definitely more of a challenge getting good top surfaces with a 0.6mm nozzle.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: First layer height 0.6mm nozzle

@bobstro

In the before gcode I turned down the "M221 S95" command to "M221 S92" and got a smooth, flawless top layer. I'm guessing this is similar to extrusion factor. Haven't checked yet but this probably affects wall thickness measurements. So this is definitely some sort of over-extrusion issue on my end. Although you don't have this problem when printing with my settings.

RE: First layer height 0.6mm nozzle

[...] In the before gcode I turned down the "M221 S95" command to "M221 S92" and got a smooth, flawless top layer. I'm guessing this is similar to extrusion factor. Haven't checked yet but this probably affects wall thickness measurements. So this is definitely some sort of over-extrusion issue on my end. Although you don't have this problem when printing with my settings.

Ah, OK. That is the set flow percentage parameter. You are exactly right. Just a few thoughts:

- If you adjust flow in your startup gcode, it will impact every print made with that printer setting profile.

- If you adjust flow using the Filament Settings->Filament->Extrusion multiplier setting, it will have the same effect but only for prints made using that filament.

- These settings are cumulative. Try to make settings in one place only or your can wind up chasing your tail, increasing one then decreasing the other. I caught myself doing this early on. I finally modified that Prusa-supplied startup gcode command to only reduce flow on layer heights over 0.32mm as that's where I notice the excess most. That way, my default settings are good for my most common prints with "normal" layer heights. Otherwise, I only make adjustments in filament profiles.

Glad you're getting it under control! I find 3D printing a lot more like cooking than building. Lots of subtle changes can make a big difference. Bon Appétit !

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: First layer height 0.6mm nozzle

Checked mine and I am using M221 S100 and from that torture test, the top layer on the 3 RHS arms is in my opinion over extruded, yet the top layers below and above the 16 pillars is perfect, so there is definitely some sort of extrusion variance being applied between short top layer moves like the arms (<5mm) and top layer moves like the 25 mm cube.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: First layer height 0.6mm nozzle

At one point, one of the Prusa developers indicated they would be looking at top layer consistency issues. Not sure if it rates highly on their priority list. I see similar issues with Cura, so I don't think it's a PrusaSlicer-only issue.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: First layer height 0.6mm nozzle

It's hardly causing an issue, just an observation to be honest. So a relatively low priority. I'm going to see if I can adjust anything using modifiers for bits where finish is important, but initial (1 minute) checks haven't found anything. I have to go to bed, as I have to get up shortly..... Good night all....

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: First layer height 0.6mm nozzle

Currently printing parts for my LACK enclosure with this SUNLU PETG on my Skelestruder at 215 Deg C and running at 150% speed.

It's not a structural part, just a filler between legs and at this speed it is coming out satin rather than gloss, looks quite good actually, hides any imperfections. 😀

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: First layer height 0.6mm nozzle

@chocki

Nice! Have you considered a volcano hot end upgrade? I'm pretty close to getting one to crank up the speed on this 0.6 nozzle.