First layer

Hello everyone,

(First of all I'm Dutch so English is not my first language but I'm going to do my best to explain)

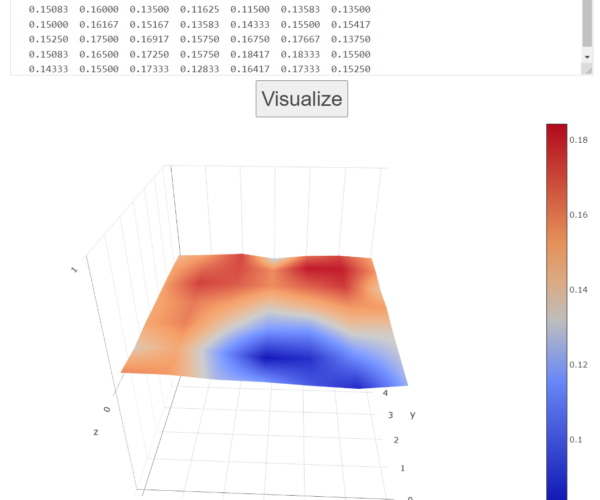

I have a MK3S+ for little over a year now and I'm having trouble getting the first layer consistent all over the bed. As you can see for some places the nozzle is too high.

I've done the nylock method for the bed.

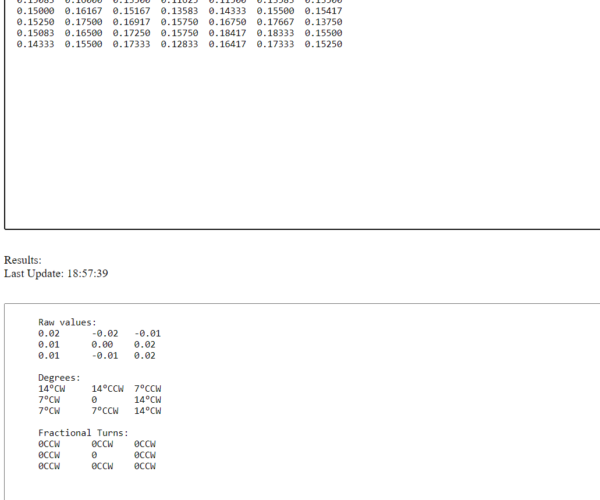

7x7 points

I have the feeling the first layer can be made better but allthought I've spend many hours researching the internet I can't seem to find the right solution. It might also be that I'm having trouble understanding the technique between having a level bed and the automatic leveling the Prusa does.

My end goal is that I want the top of the 3D print to be as level as possible.

RE:

Well, that's the most discussed topic in most 3D printing forums. Let's see if I can break it down for you:

During first layer calibration you set the offset between the point where PINDA is triggered and the point where the nozzle is directly above the bed (Z=0.0).If you had a perfectly flat bed, completely parallel to your x and y axis and no variation in the coating of your sheet you could now print perfectly after homing and without mesh bed leveling - unfortunately you don't have that, so you can't stop here.Now comes mesh bed leveling, it compensates small deviations from the axis and an not perfectly flat bed by measuring the difference between the PINDA trigger points throughout your bed, interpolating by x/y position and adding that difference to your z-position. The more your bed is parallel and flat the less the corrections by mesh bed leveling are and the more precise your prints are, so you want a flat and parallel bed and let mesh bed leveling do the rest.To make things more complicated and give perfectionists something to do, Prusa introduced an additional Bed Level Correction ( https://help.prusa3d.com/article/bed-level-correction_2267 ). You can use this to introduce another x/y position based offset into the mix, if you do, you basically compensate for things PINDA can not detect, this would be variations in coating (because PINDA is triggered by the metal, not the coating). Be aware, that using this corrections can already work to your disadvantage as soon as you turn the metal sheet or change to a different one.

If you used the nylok method, you know that PINDA measurements change from measurement to measurement even without any changes made, so trying to get the variance of your first layer below a certain point is impossible because of the measurement variance of PINDA being transferred to your first layer by the mesh level correction. Your first layer looks pretty good and if adhesion is good all over the bed you are done.

Regarding the top of your print: I am not 100% sure about the Prusa firmware but usually Marlin washes the bed level correction out over the first few layers, so the top of your print should be as level as possible.

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!