Filleted edges problem - how to solve?

Hi!

I need your help. I have read several topics in the forum. I already used different settings of extrusion width, speed external perimeters, adding perimeters, lowering the temperature to the PLA, removing the top and bottom solid layers. And nothing seems to work!

Layer: 0.1mm

Nozzle: 0.6

Sorry for my English

Filleted edges problem - how to solve?

Add 3mf in rar

Nor surprised, its going to be very difficult, possibly almost impossible to print such a steep overhang with the nozzle size you have. That second layer perimeter is literally printing over nothing in mid air. Even with a 0.4 nozzle its still mid air.

May Swiss can figure it out but personally I'd bet on that being unprintable on any normal printer

RE: Underside fillets don't print well

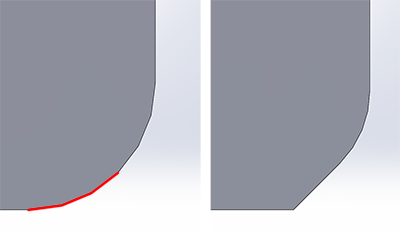

As @neophyl notes, the fillet on the underside is going to be difficult to print. You can improve it slightly, but it if this is your own design, it would be better to avoid the problem altogether. This pic highlights the issue:

If you can tweak the design, use a chamfer partway up, then fillet when the overhang angle won't be as severe. 3dverskstan has a good article showing this approach.

If you can't modify the design, gravity is your problem. You can try lower layer heights and wider extrusion widths at lower layers to improve the width-to-height ratio and extrusion weight, but expect to see some deformation. Maker's Muse has a nice video on this topic for designers.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Just fix it 🙂

Even if it isn't your own design, you can adjust that bottom edge to be 45 degree angle and save the changed STL.

.rar comes back as damaged or unknown format, using Winrar.

Regards

Swiss_Cheese

The Filament Whisperer

@swiss_cheese

Zip-file, haven´t done anything with it, just "repacked" it. (I use 7-zip)

Prusa i3 MK3S+ FW 3.11.0 (kit dec -20), PrusaSlicer 2.6.1+win64, Fusion 360, Windows 10

Thanks Ringarn67 it opened right up.

The Filament Whisperer

Why the support blocker?

Add 3mf in rar

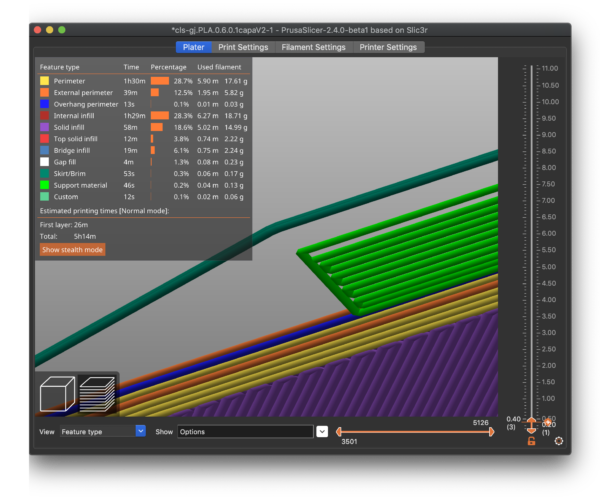

You have added a support blocker, so unsurprisingly, supports aren't being printed under the worst of the overhangs. Even with support, results won't be ideal. Spend some time examining the sliced print in preview mode before printing. Here's what your 3MF shows after slicing:

Notice:

- The blue lines. These are flagged as overhangs that require support or adjustment.

- The yellow lines at the bottom. These are internal perimeters (yellow), not external (orange). This indicates a severe overhang that will be difficult to print.

You're using 0.1mm layer heights, so there's little more you can adjust there. Wider extrusions can only help so much. You can try improving cooling. The root problem remains that filleted underside. You might be able to improve the appearance, but expect it to not present as nicely as a properly designed print.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…