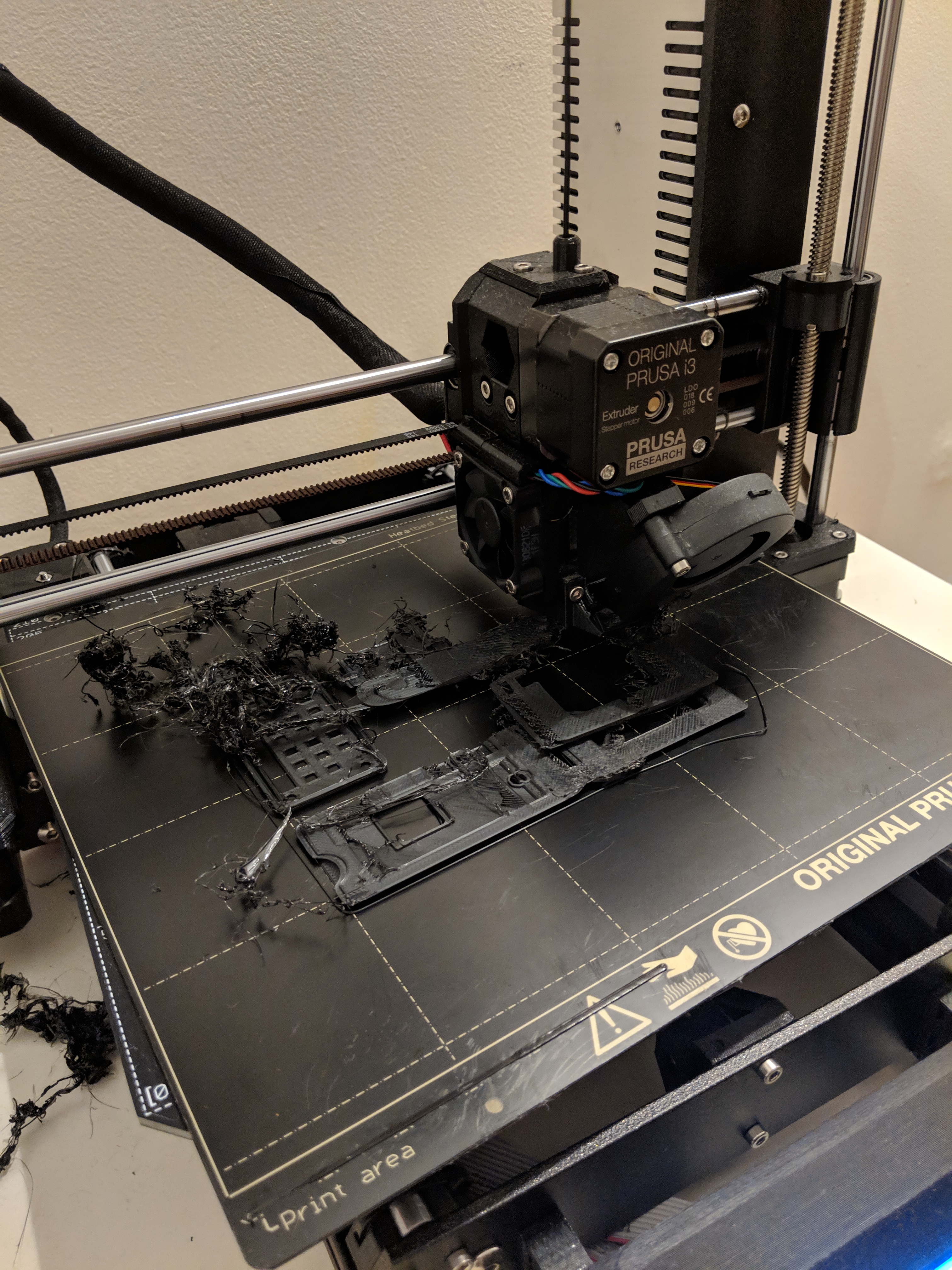

Failed print

Hi. I'd like to get some input about this failed print of some parts downloaded from Thingiverse. Used generic PLA at .1mm detail, some parts with 100% infill and the rest with 20%; and I kept all other settings with the default slic3r values. I had used the same roll of black PLA filament shown in the pictures with the same slic3r settings in the past, without issues. But, as shown below, the results were not pretty this time.

My main questions are:

(1) What could have caused the print to fail like this?

(2) Why would the magnetic heatbed shift (so much) from the original, fully aligned position without stopping the print due to a crash detection? (The printer was running in normal mode, at 30% speed, with crash detection on.)

(3) What settings can I try for my next printing attempt in order to avoid this issue?

Thanks

Re: Failed print

If none of the parts have lifted at a corner causing a crash... maybe you got bit by this? Looks like you have a layer shift before things went completely haywire.

Re: Failed print

I'm curious what the final part would look like. But based on what I see, it looks like a combination of a corner lifting and excessive overhangs curling.

That said, might be worth checking the X-Axis belt tension and drive gear attachment: a gear slip on the motor shaft may explain an initial X shift.

Re: Failed print

Thanks for the answers so far. Here is the intended design. Hopefully it helps.

Re: Failed print

I don't see any supports for the eye tangs on the rod part, nor for the two small pins that are certain to break free during a print. And if either of the two square parts towards the back of the bed are open underneath, it's another bridging area that is subject to failure. Since I don't see the square part that looks like it is facing down on the bed, that may be the one that failed second (after the two pins went missing).

Educated guesswork .. ymmv.

Flip the square pieces so the open areas are UP, and flip the two pins so the flat end is down.

ps: total print time will be about the same if you split the parts up and print them one at a time. Just a few more "print from SD" operations.

Re: Failed print

After fixing a few rookie mistakes, the parts printed without issues:

- Apparently I had forgotten to add supports (I may have made a last minute change in the slicer/print resolution that reset the settings to the default values)

- Some parts were not oriented correctly, had to flip them to lay flat on the bed

- The filament spool was getting tangled. After reading a few articles on this topic, I have a better appreciation for the popularity of the printable filament clips intended to maintain the filament in place when stored.

Thank you all for all the tips!

Re: Failed print

I just thread filament ends into the holes on the spools. Works well, nothing to lose, and limits finger oil contact with the filament (which causes other problems).