Design / Print Strategy Question for this model

Right, so I have designed a custom crown guard for my table saw that will allow me to hook up to an overhead dust extraction system (see 3 pictures below). It will be printed from ABS on my Mk3. What I'm not 100% on is how best to go about printing and assembling this. I will walk through my current plan and would welcome comments.

- I have split the model into two parts purely based on size - you can see the dovetail joint on one side.

- The larger (rear) part is approx 20cm in length, and the smaller (front) part approx 10cm.

- For the rear, I intend to print it the "right" way up, which would just mean I need support structures in two locations, one at the back just infront of the horizontal round hole to support the ledge inside the guard, and one near the front of that piece to support the front slope of the transition up to the round connector.

- For the front I will print it upside down (supports therefore needed for the early part of the curve as it comes up from the horizontal).

I'm relatively new to printing so I'd welcome suggestions!

Thanks.

Re: Design / Print Strategy Question for this model

Looks like whoever designed it already made mods for printing.

Split at the line with the "tab", print the right half as shown, rotate the left half by 90 so the "tab" notch is down. Simple supports needed only for the "tab" on the right side. Selecting "Detect bridging" is a good idea for the one overhang inside the right part and the two screw holes. But you could modify the tab so it doesn't need supports at all.

Re: Design / Print Strategy Question for this model

I designed it!

How did I miss turning it on end?! Can't see the wood for the trees.

Thanks for that!

Re: Design / Print Strategy Question for this model

Hi Rick,

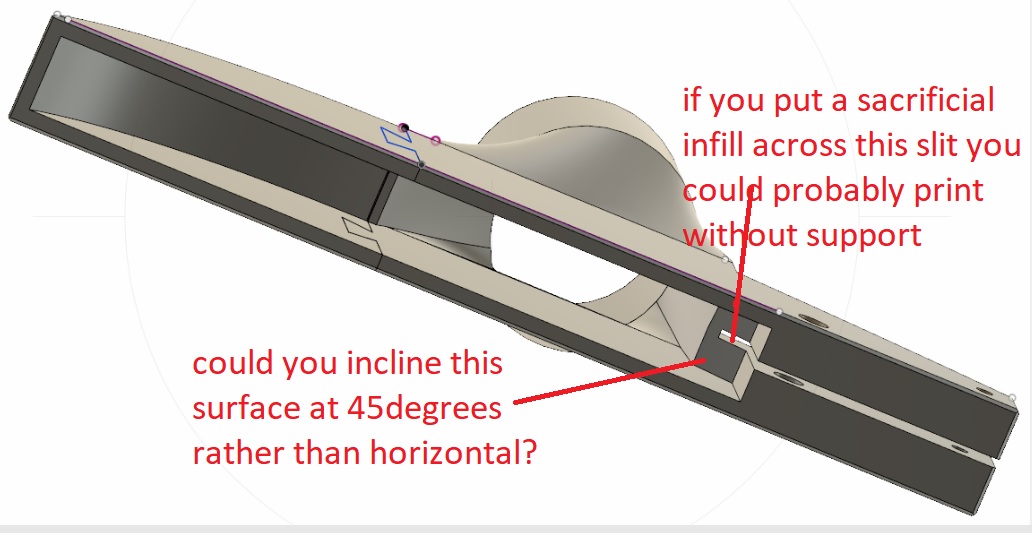

couldn't you print it in one piece, diagonally on the build plate? looking at the picture below, consider the flat face you are looking at, as the bottom

the underside of the part you call the front, should bridge the gap, if you leave the design as it is...

but you could change the design a little and make it even more likely to print well... see below the diagram

the ledge with the slit... does it need to be horizontal?if it could be 45degrees upward into the waste vent, it would print without support

if it does need to be horizontal, then you could add a thin sacrificial web across the slot say 0.6mm thick, that would be enough to support the filament bridging the gap, then you could cut the web out, later

if it were acceptable to re shape the front section to have a curved top instead of a flat horizontal top, it would print better than bridge the gap...similar to below the revised shape would probably be more robust and less likely to collect dust in the corners, too

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Design / Print Strategy Question for this model

Wow, thanks Joan.

I'll double check the diagonal suggestion but I don't believe it will fit from memory.

I'll do youtlr 45degree idea for that ledge, there is no reason it can't be, thank you.

You made that mockup very quickly! I need to get out of a CNC mindset where curves add problems, I can see exactly what you mean and that would work absolutely fine, I will modify the design.

Thank you so much for the suggestions and taking the time to do the mockups.