Crash Detected

Hi. New at this, and I'm trying to print some dungeon terrain pieces for tabletop gaming. My first attempts had some lifting of the piece on the corners, so what should have been a perfectly flat bottom was slightly curved and the whole piece rocked. My attempted solutions were to a) improve temperature control and b) increase the infill from 20% to 50%. Now I'm getting crashes. Shortly after it starts the infill, it says "crash detected," resets the x and y axis, and then resumes printing - twice. The third time it crashes, it suspends printing and there's a "continue printing y/n" message onscreen. If I pick yes, it repeats the cycle, crashing three times, and suspending the print on the third crash with the continue printing option. I had the same problem with another model earlier, and I kept picking yes until it got past the problem layers and finished the print. My questions:

1. What could be causing the crash? Is there any way to diagnose and potentially correct this, or is it a problem with the source .stl?

2. If it can't be corrected, can the printer be set to ignore the crashes and keep restarting the print without my intervention?

Thanks.

RE: Crash Detected

Hello and welcome to the forums.

It would help to know what type of printer you have, what material are you trying to print, and which print sheet surface you are printing on.

It would also help the people here to diagnose your issue by including some photos and attaching a .3mf project file to you post so others can see the model and all of your settings in PrusaSlicer. You have to zip the file or the forums won’t allow the file attachment.

New members generally need to have made a number of posts before pics or files can be added.

In the meantime, since you said you have corners lifting from your print, that warping will cause you no end of problems until you get it sorted. Increasing the infill percentage will likely make warping worse, not better. Certain infill patterns have areas that cross each other, potentially creating a small spike or bump at the junction. This can lead to a crash. The higher the infill density, the more opportunities for a crash. Warping can also lead to a crash.

Tell us more about your setup, what you’ve printed successfully, how many successful prints before these problems began, anything you’ve tried to do to remedy the situation. The more information you can provide the community, the better the quality of the help you can expect.

Cheers

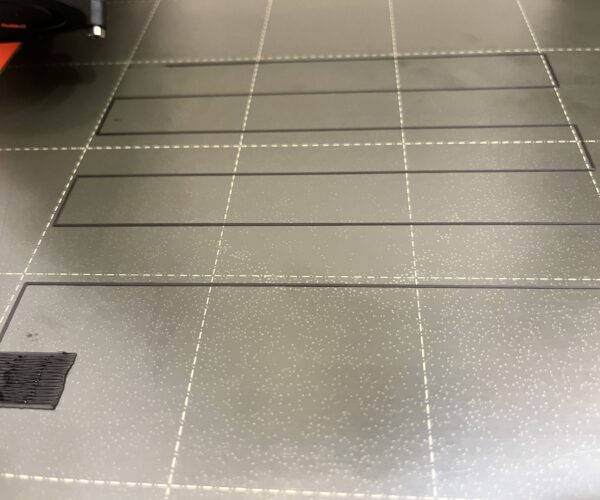

Please show us the underside of a failed print.

Please run a first layer Z calibration and show us the resulting print *on the print sheet*

Cheerio,

RE: Crash Detected

Hi, thanks for the responses.

I have an i3 Mk3s+. I'm printing ASA, and the print sheet is the one that came with the printer.

Linked below (I think) is a zip of two pics including the underside, and the .3mf file of the original attempt with 20% infill. Pic of the first layer calibration coming after work today.

Thanks again for the help.

You have adhesion issues with warping which will allow the model to curl and lift into the path of the nozzle, hence the crashes.. Are you using an enclosure? Larger ASA parts will warp badly without protection from drafts, especially so at higher levels of infill. Is there any particular reason not to use PLA for this model?

It's hard to judge the first layer from this picture but it's not too far off.

Cubic would be a better choice of fill pattern than stars for structural stability.

I would probably print this at 0.2mm layer height, especially if it will be painted.

Cheerio,

RE: Crash Detected

I'm using ASA because my understanding is that PLA doesn't hold paint very well. If I can use a more forgiving material that I can still paint, I'm all for it.

I've built an enclosure in my garage which I'm able to maintain at a temperature of 78-85 F and about 35% humidity.

Will try cubic infill next attempt. Line height is currently 0.15.

Cheers.

PLA is fine with standard modellers' enamel, I use Humbrol; for other paints spray with primer first.

In general, test print and test paint. Internet 3D printing 'advice' should always be taken with caution, including mine.

For some reason PLA has a very poor reputation in 3D printing when in fact it's an excellent plastic when used according to its strengths. You shouldn't need to close your enclosure for PLA unless you get severe winter weather.

Cheerio,

RE: Crash Detected

I've painted PLA but I've never really got it to dry thoroughly. Tried primer, tried talcum powder, tried drying spray. Always stayed a bit sticky and tacky.

Closest I get is to use a coat of that clear coat floor polish.

@jason-andriulaitis

Yes, that is a fraction too low, raise it until those waves *just* go away.

You have fingerprint marks on your print sheet, look up threads here about cleaning it.

@annier

The first coat tends to wick into the layer structure, if it is dilute the surface absorbs rather a lot of the solvent medium ... which leaches out for a long time. For a first coat use either slightly sticky enamel or a very light spray of primer. This should then proof the surface for later paint.

Cheerio,

RE: Crash Detected

ASA usually needs an enclosure, not only to provide elevated heat to help with bed and layer adhesion, but also to help prevent harmful fumes. The S in ASA stands for Styrene and can cause headaches and fatigue. If you want to print ASA, you should also consider a filtration unit inside your enclosure to suck out and filter all the fumes while printing, otherwise you'll inhale all the fumes the second you open the enclosure doors.

RE: Crash Detected

Hello

Try using a different slicer software to generate the G-code for your model. Sometimes, different slicers can handle models in unique ways, which might help avoid the crashing issue. If the problem persists, inspect your printer for any mechanical issues or loose parts that could be causing the crashes. If you're unable to identify and fix the issue on your own, consider reaching out to the manufacturer's support or a community of 3D printing enthusiasts for assistance.