CPE problem - unclean surface and poor quality print

Hi everybody,

after a few quite good prints with Fillamentum CPE HG100 I must have done something wrong as the current project comes out rather badly (see images).

The main issue is the poor quality of the top surface. By the looks of it that seems to be partially the result of stringing on lower layers that gets embedded in the structure.

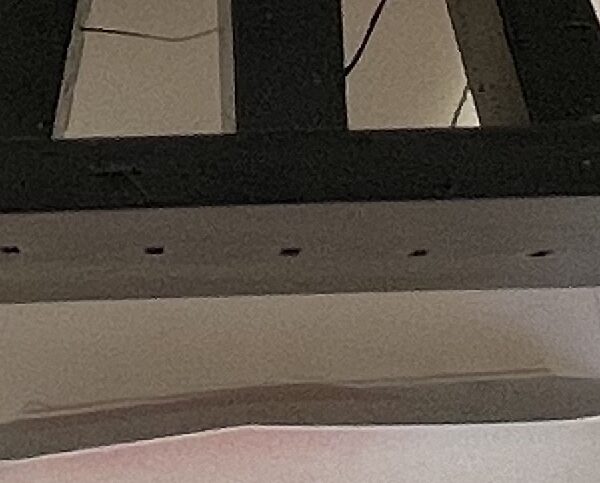

Printed on the smooth sheet with good adhesion and no sign of warping. In fact there is a degree of inverse warping, which most likely happened after removal from the bed.

The filament has been opened for a few months but dried before usage (5h@70degrees) and used directly from the dryer.

z-adjust done with the same filament directly before printing the large part (images attached)

Nozzle is a brand new Olson Ruby ( was printing some abrasive stuff and didn't change back to the plain brass nozzle)

Print ran over night and it got a bit chilly in the room (approx. 15 degrees, winter is coming in Aotearoa)

Very curious to read any suggestions on how to improve this thing.

Thanks in advance

Hansjoerg

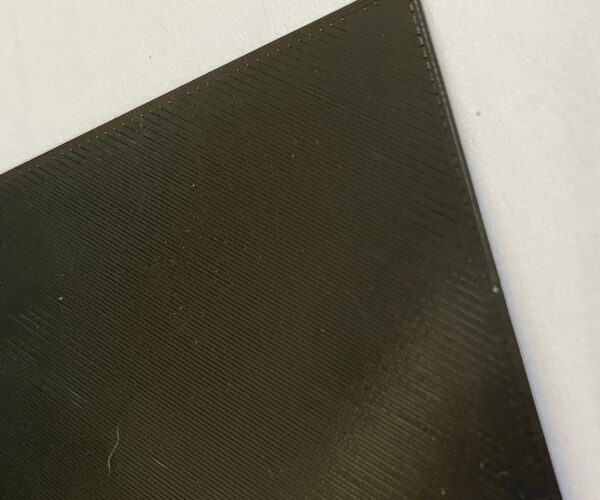

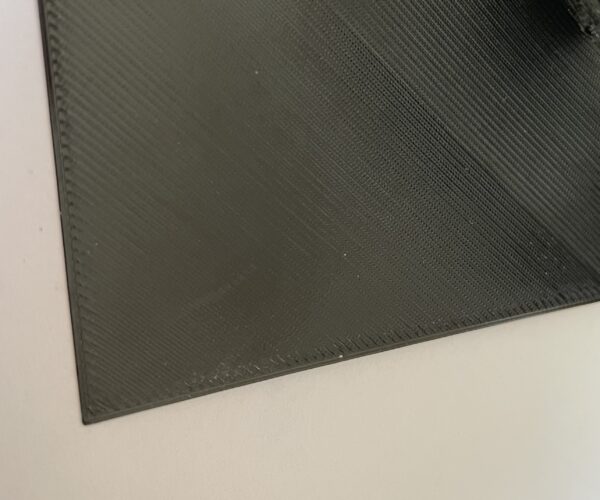

calibration square, bottom view

calibration square, top view

"inverse" warp

RE: CPE problem - unclean surface and poor quality print

I am assuming you are talking about the hatch-lines on the surface of your very thin sheet.

Consider that layers below are showing through the very thin top layer. You may want to add a few more top layers, or change to an aligned top and bottom infill. I am guessing that there are not very many print layers happening here - which means you don't have a lot of opportunity to clean up top surfaces and still maintain dimensional integrity to the sheet thickness.

There also appears to be globbing. I cannot tell from the pictures if you ever show the bottom layer.

From your calibraton square shots, I would submit that your Z is not low enough - the lines should merge completely, but not get wavy.

RE: CPE problem - unclean surface and poor quality print

Hi Dan,

thanks for your thoughts.

There are 5 top layers and so far this has been quite sufficient to clean up things. The whole sheet is 20 layers thick (4mm @ 0.2mm layer height). With 4 bottom layers practically almost half is 100% infill. I guess this contributes to the bending.

Regarding the Z, lowering it by a further 0.02 results in an even wavier appearance of the top side. Thus I assumed that that would be too low. Feeling along the bottom it is very smooth. For a next test I will lower it by the 0.02 and reduce the extrusion multiplier (currently at 1) to 0.97. Maybe that will help. It would be a shame if I had to change the material as I really like the glossy appearance of the CPE.

RE: CPE problem - unclean surface and poor quality print

If the ambient temperature changed a lot during the print then warping is more likely, it might be enough to leave the heating on for the odd long print but perhaps it's time to consider an enclosure. You can test whether it would be effective by putting a large cardboard box over the printer as a temporary measure.

Before changing the extrusion modifier try enabling 7x7 mesh bed levelling and slow down the first layer a little.

Cheerio,