Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

hope it helps. trouble shooting a mk3 single is fun...compared to mmu added on top of it stuff 😀

it's sad.. at work I fix printers...at home for a hobby...I fix printers..

Ouch. I was so close to pulling the trigger on that MMU2 too. Someday.

Two more images of the printer settings in Slic3r. They should all be the defaults.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

the mmu works good. after getting the proper troubleshooting down. its been running non stop for like 6 months now. I would say it gets sick every 2 months. and I do think the "S" mod should help.

on average I would say 1 filament path gets touchy once a month... and im stopping at that 😀

it's not hard to deal with a " well I cant use filament path 2 this week..."

good gods why did I get it.. I HATE ptfe tube Bowden stuff... it's lame.

I have a Prusa,therefore I research.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

Just ran another NASA log in Prusa PLA after reverting the firmware. Seems improved but still under extruding, and this time I got a missed layer wall.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

those sides show up allot better in that picture.

what happens if you print at .3mm layer or 1=.1 mm layer any better? sorry if you said this stuff already. don't know why I didn't have your list of stuff you've done in my temporary storage,,

I have a Prusa,therefore I research.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

those sides show up allot better in that picture.

what happens if you print at .3mm layer or 1=.1 mm layer any better? sorry if you said this stuff already. don't know why I didn't have your list of stuff you've done in my temporary storage,,

That blue NASA Sphere was at 0.1mm, but the 0.2 mm layer height NASA Logo I printed in blue yesterday morning came out well.

As of about 10 minutes ago I loosened the tensioner door completely, tightened it until it just grabbed the filament then gave a 1/4 turn more, and readjusted the first layer Z offset by printing a 20mm single layer square a few times. I only tweaked that about 0.01mm closer to the bed. Trying yet another print after those tweaks.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

if it helps. pla my "tensioner door " screws are flush without filament. been that way for a long time.

I have a Prusa,therefore I research.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

One other possible source for under-extrusion is debris in the heat break / PTFE channel. Pop the nozzle out and blast air up and down the filament path. I was greeted with a mushroom cloud of dust the first time I cleaned mine out. No clue where it gets trapped, but it impressed me.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

One other possible source for under-extrusion is debris in the heat break / PTFE channel. Pop the nozzle out and blast air up and down the filament path. I was greeted with a mushroom cloud of dust the first time I cleaned mine out. No clue where it gets trapped, but it impressed me.

I had just swapped my PTFE tube but I am more than willing to try it again.

Trying yet another print, and you can see the second layer is very lacking.

Well, the photos is not as revealing as I hoped, but I can see black through both layers.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

If you just lifted the PTFE up and out the dust may still trapped down in the heat break. My pet theory (call me crazy) is that dust packs around the filament and forms a sleeve in the 2 mm heat break. And with time and temp it compacts and eventually chokes the filament - sort of like a Chinese Finger Trap. The dust is in the cold side of the heat break and isn't melted, it is still dust, but it packs tighter and tighter. Anything that lifts the filament a bit "resets" the choke hold. And it starts all over with the next print.

Sounds outlandish, I know. It took me a week solid of trial and error to find it the first time it happened to me. I had been printing glow filament, and was plagued by random plugs - the glow particles are large, very hard, and jagged - they catch in the nozzle orifice. But with each plug came clicking and dust. When I switched back to normal PLA the weird things started. Under-extrusion, a plug an hour into a print; yet full flow if I tried a manual extrude... I was pulling my hair out. I decided to swap the nozzle again (second time) when I decided to blow air everywhere to clean the bondtech area, filament sensor, and extruder in general. Wasn't really thinking about the heat break at the time. But I pointed the air can tube up from the bottom and was greeted with a cloud of dust. Found it by accident.

It may not be what is happening in your case, but it is a possibility.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

If you just lifted the PTFE up and out the dust may still trapped down in the heat break. My pet theory (call me crazy) is that dust packs around the filament and forms a sleeve in the 2 mm heat break. And with time and temp it compacts and eventually chokes the filament - sort of like a Chinese Finger Trap. The dust is in the cold side of the heat break and isn't melted, it is still dust, but it packs tighter and tighter. Anything that lifts the filament a bit "resets" the choke hold. And it starts all over with the next print.

Sounds outlandish, I know. It took me a week solid of trial and error to find it the first time it happened to me. I had been printing glow filament, and was plagued by random plugs - the glow particles are large, very hard, and jagged - they catch in the nozzle orifice. But with each plug came clicking and dust. When I switched back to normal PLA the weird things started. Under-extrusion, a plug an hour into a print; yet full flow if I tried a manual extrude... I was pulling my hair out. I decided to swap the nozzle again (second time) when I decided to blow air everywhere to clean the bondtech area, filament sensor, and extruder in general. Wasn't really thinking about the heat break at the time. But I pointed the air can tube up from the bottom and was greeted with a cloud of dust. Found it by accident.

It may not be what is happening in your case, but it is a possibility.

It makes a lot of sense since the issue first happened with a PLA silk. I did change the PTFE tube but I really wish I had blown out the heat break more. I think tomorrow I may pull the nozzle, then remove the hot end assembly...again, pull the tube and try to make sure that whole pathway is clear before reinserting the PTFE tube. It if isn't that then I am all out of ideas and may be hurling the hot end out into the yard.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

Thinking I probably should have posted this in Hardware after looking around some more. Still as of yet unresolved. I am closer after messing with it until 2AM, but I will likely pull the nozzle and heat break and hit both with the air compressor.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

An update!

Once I got home and was feeling very mellow, I went to work.

2. Continued heating the nozzle to 280C and removed it, then set the machine to cooldown mode

3. Disassembled the extruder enough to remove the hot end, this get easier each time

b. When I removed the motor, two very thin strands of blue filament fell out from somewhere, not sure where

4. Checked heatsink fit, removed PTFE tube

5. Used air blower to blast out the heat break and heatsink assembly, PTFE tube, and the filament pathways

6. Reinstalled PTFE tube, triple checking the fit and blew air threw again

7. Reinstalled nozzle while the heatsink was out to insure it snugged everything out and reinserted the hot end assembly

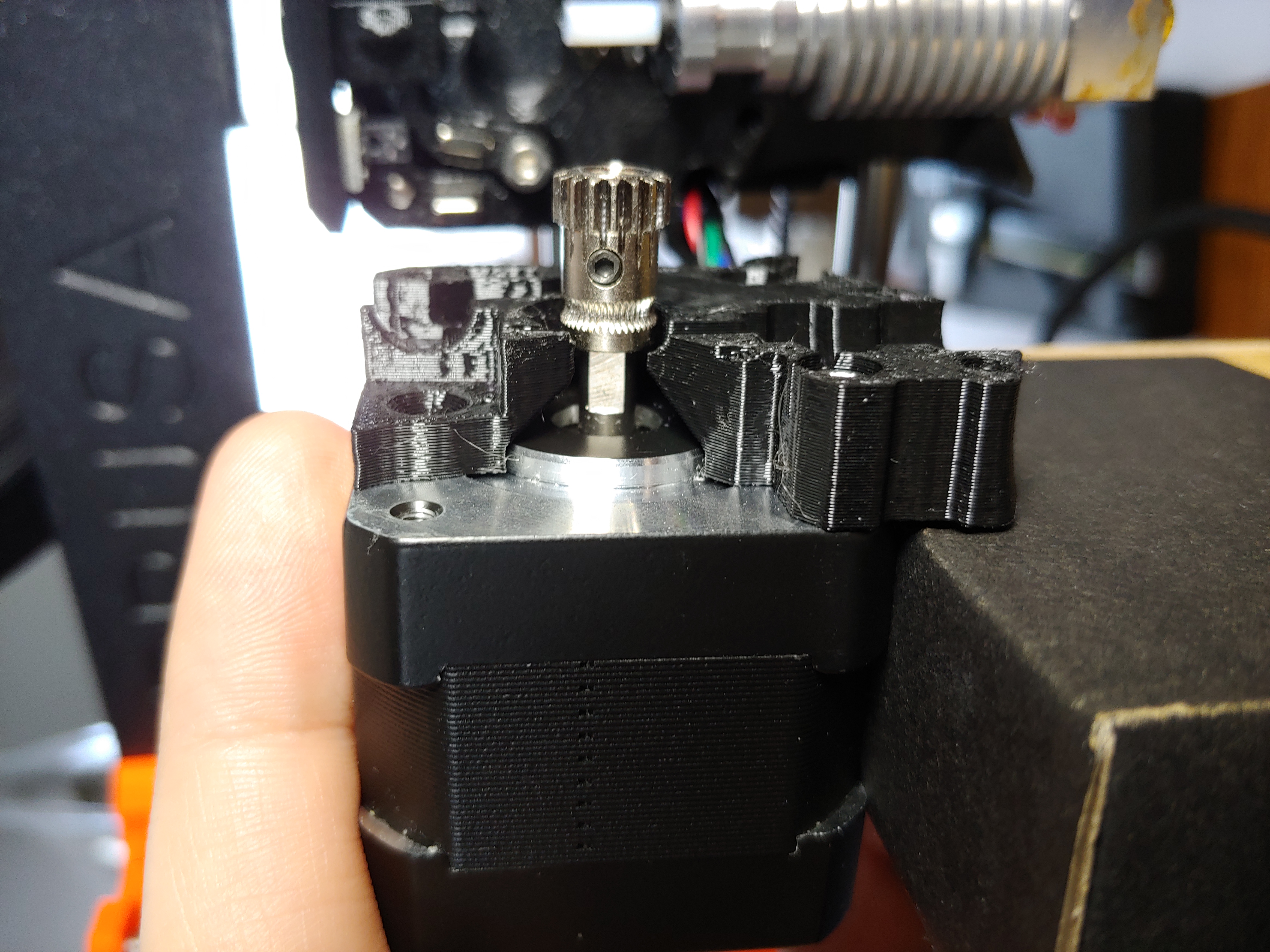

8. Prior to reinstalling the motor I took a good look at the Bowden gear and noticed it was tight but the setscrew was against the curved segment of the driveshaft, so I reseated it, verified alignment, and insured the setscrew was a-against the flat side of the shaft

9. Reassembled extruder, and sanded down the top edge of the tensioner door. Mine had a weird binding tendency with the filament guide cap in place, and now it rotates smoothly.

10. Prior to installing the filament fan, but after the cooling fan, heated nozzle to 280C and snugged up nozzle

11. Finished reassembly after cooldown

12. Set tensioner to just grab the filament, plus a full turn, when loading

While the calibration was running I thoroughly washed and used acetone on the print sheet to freshen it up. I also used the mentod of printing a 20mmx20mm one layer square to dial in the Z axis, which worked WAY better than the stock method I think.

So far it is looking pretty good on the print, we’ll see if it holds.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

strands of blue filament , and the setscrew for the gear was a good find

I have a Prusa,therefore I research.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

Forgot to mention, after the cold pull the nozzle looked new. The very first time I pulled the nozzle, waaaay back, id had a thick ring of white filament that I had to melt out, but I was printing with gold. Not sure if the white was so caked in because it was PLA+ and I was printing lower PLA temps or what, but next time I switch from PLA+ to PLA I'll either run hotter at first of maybe do a cold pull to remove the PLA+.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

Here is where we are at now. Bed adhesion is better than ever after cleaning, and I am honestly not sure at this point if my Z-offset it too high or too low. I am thinking I am a hair too close to the bed judging from what appears to be some filament push. His top layer is decent, not great, but not a failure. It was printed with the included Prusa silver PLA, for the most part using the Slic3r PE profile for it, although I bumped up temps near the top layers between 212-214C. Most of it printed at 70% speed with the top layer at 50%.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

Quick update, after many attempts to dial in my Z offset using the PRUSA silver PLA and 5 runs of this handy gcode: https://shop.prusa3d.com/forum/assembly-and-first-prints-troubleshooting-f62/life-adjust-z-my-way-t2981.html I finally ejected the PRUSA filament and switched back to eSun. Once I swapped I was able to dial it in very quickly, and it is printing as good as day 1, maybe better.

The PRUSA silver was just fighting me along the way. I'd have two test squares, same Z offset and same temp, come out differently with issues. Could not get it dialed in. I think this roll is going in the oven for a bakeout.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

that's a shame about the prusa silver. but im sure it can happen.

I have a Prusa,therefore I research.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

I'm curious if the silver PLA filament is Prusament Silver or the older Prusa unbranded.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

I'm curious if the silver PLA filament is Prusament Silver or the older Prusa unbranded.

Some folks have posted bad results with both the new prusament and older versions.

--------------------

Chuck H

3D Printer Review Blog

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

I'm curious if the silver PLA filament is Prusament Silver or the older Prusa unbranded.

Its the older stuff that I got, not the Prusament.