Colorfabb ngen flex adhesion and warping

With the Prusaslicer profile and textured sheet I'm having big problems with bed adhesion. The printer prints only a couple of layers before the print is released from the bed.

The second issue is that overhangs curl up like crazy, which doesn't help either.

Does anyone have tested print settings or a trick to print this material?

Best Answer by KPS:

Smooth sheet supplied with MK3S+ circa May-June 2022. Sheet is rigorously cleaned with 70% PLA after every (as in EVERY print) without exception. Cheers... KPS

RE: Colorfabb ngen flex adhesion and warping

Can you supply a picture and description of the item you are trying to print along with your current settngs? I will have a look at what you can provide and may be able to give you some tips. We use this filament in house with great success. Probably our Go To filament for general use.

RE: Colorfabb ngen flex adhesion and warping

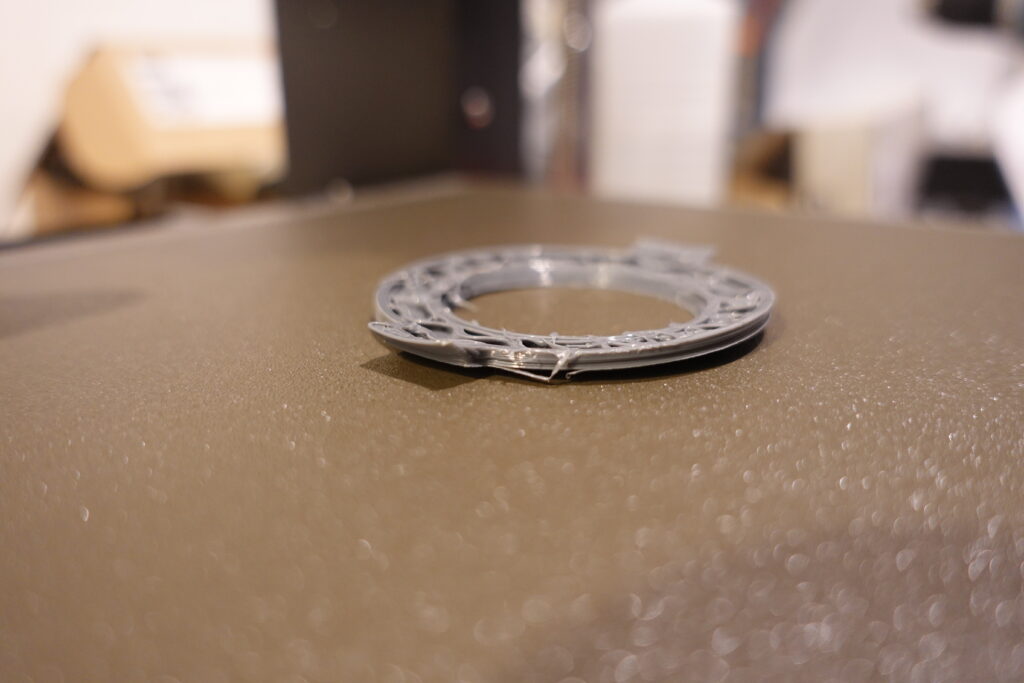

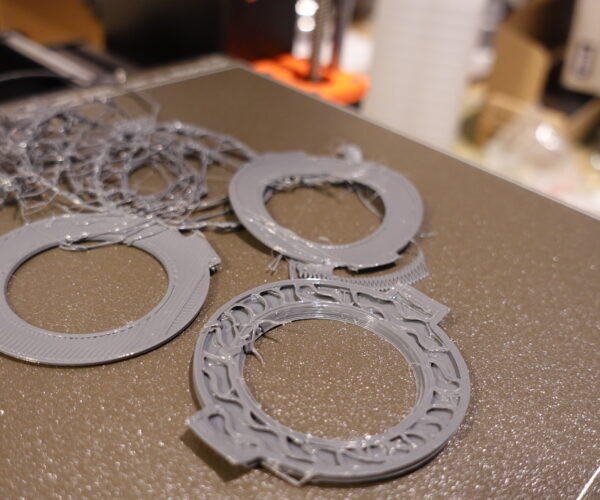

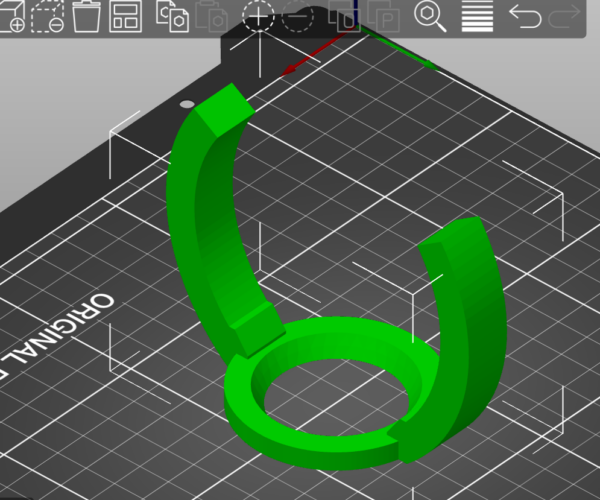

The print is a handle for a baby bottle. Similar to https://www.printables.com/model/282151-handles-for-medela-baby-bottle but a different brand.

I included some pictures of the failed prints. The bottomside shows no gaps or poor contact with the buildplate.

Nozzle is 0.6mm and profile 0.30mm quality with standard ColorFabb ngen flex preset.

RE: Colorfabb ngen flex adhesion and warping

Are you printing on the smooth or textured sheet?

RE: Colorfabb ngen flex adhesion and warping

Smooth sheet supplied with MK3S+ circa May-June 2022. Sheet is rigorously cleaned with 70% PLA after every (as in EVERY print) without exception. Cheers... KPS

RE: Colorfabb ngen flex adhesion and warping

Thanks a lot KSP with the smooth sheet i managed to print the model. The model still came lose but only half, so the print completed. I added a brim as well. The interesting thing was that the brim was almost glued to the printbed, but the model separated (half) from the brim and bed. In any case I will clean even better next time. Do you mean 70% IPA instead of PLA?

RE: Colorfabb ngen flex adhesion and warping

JZ... yes 70% IPA... sorry... thinking too much about filament!

My experience is that the brim is thin enough that it may not separate at the outer edges of the brim but the model will lift and also lift the brim where the brim contacts the model.

Here are some of the settings that I have found worked best (so far) here: wBrim_Fan40-60_NGEN_Nozzle230-230_Bed85-85. Ambient temp ~ 20-22C inside enclosed (DIYstyle) MK3S+ The first number in each cuplet is for the first layers and the second number in each cuplet is thereafter. With this setup we ended up with less than .5mm warping at corner ends of a model that is about 140 mm long and that takes 4+ hours to print.

Not sure this helps but when examining a test print, where the model warps, on the flat side that faced the plate during printing, in the correct lighting you can see a very low amplitude ripple pattern oriented like a pebble produces in a pond, gradually fading inboard away from the edge or corner. I noticed that as I experimented with the settings (Fan was important) that as I tested, the warping was reduced as I reduced the fan values (I avoided below Fan 40 from something I read somewhere about clogging) and the ripple pattern was smaller in extent and amplitude until, when I had the fan at 40-60, the ripple pattern was gone and the warp was down to less than .5mm. From the various tests the ripple is associated with warping and when you may have a very small warp at a corner and no ripple pattern on the smooth side you may be as close to perfect as you are going to get. I have not experimented further once I had NGEN warping not significantly different than I had with printing the same model using PLA or PET-G. I wanted the toughness, heat resistance and appearance of NGEN. Cheers... KPS