Clearance data

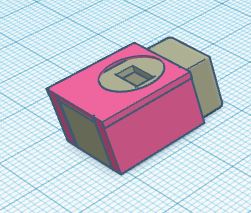

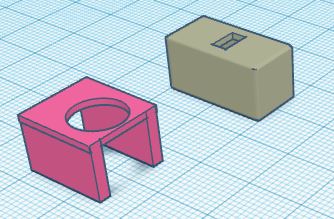

Is there somewhere where I can find data on dimensions to be used when designing PLA 3D printed parts which have to be fitted together. I want to print these two parts so that the pink part can be pushed down onto the brown part so it stays in place, unless some force is exerted to remove it. What should the difference in width be between the two parts. They are quite small, so I can do a trial and error test but it would be useful to have some data to refer to.

A soft answer turns away wrath.

RE: Clearance data

No. Its one of those things you have to figure out for YOUR printer and filament combination. As it can vary between filaments, not just type but manufacturing. Much of it depends on how tuned your printer is.

There are various tolerance models available to download from the usual sites. You print those in the filament you want to check and then design accordingly.

After awhile you get used to what tolerances are needed for your printer and your designs. Of course this doesnt help when downloading other peoples designs. With those if they have designed in any tolerance you might find that parts are loose as your printer has better than they needed to leave for theirs.

Also be aware that its best to check tolerance on both flat sided parts and cylinders/holes separately.

Holes are usually slightly undersized by the time they print out anyway. Personally for my Mk3 I can leave 0.1mm extra for a snug fit on a part but for say a hole I would use 5.2mm for a 5mm screw to get that same snug fit. 5.3-5.4 if I wanted a looser hole and 5mm if I wanted the threads to bite in a tiny amount so it didnt fall out (but I wouldnt be relying on that for the actual fixing, there I would always use a nut or similar for the actual grip.

RE: Clearance data

Like Neophyl I use 0.1 for tight fit, 0.2 or 0.25 for "normal" (some drag) and 0.3 or 0.4 for loose fit. But those are just starting points and need to be experimentally confirmed.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Clearance data

Thank you both - very helpful. I will start with 0.1mm and work from there.

I've done this before but haven't kept a record 😡 Will do better this time!

A soft answer turns away wrath.

RE: Clearance data

Thought I would report back that I ahve found that the variability between inidivual prints is such that is is not possible to define this tolerance. I printed a batch of 8 of each of the parts, and found that some paira fitted very well, while others were a bit loose - I didn;t find any that were too toght. So I think has to be suck it and see!

A soft answer turns away wrath.