CAP for Erlenmeyer flasks

Hello everyone

I am a novice in 3d printing with my Prusa i3 mk3s and above all with drawing from scratch.

I would like to ask you for help in solving a practical problem that I have encountered: building a kind of cap for glass flasks used in chemical laboratories, similar to those ones:

In practice, my problem is figuring out how to anchor the cap (at this stage it doesn't matter its size or even its shape) to the glass neck, so that it is airtight, i.e. offers a certain degree of air sealing, possibly independently of the size of the neck.

I can use Freecad, but I know very little about it and I don't know how to start.

Is there anyone who can guide me in the 3D drawing of this device?

Thank you so much in advance.

Max

openscad

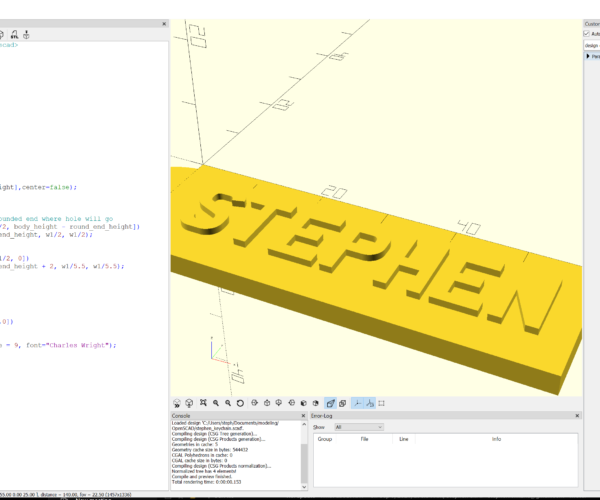

This is something that could greatly benefit from parameterization. If I were doing this I'd likely opt for using openscad.

This allows you to set variables at the top that define the various dimensions so you can generate .stl for various sizes of flask.

Their documentation is pretty good and I was able to come up with something pretty quickly.

I can attach a quick example if you're interested.

What criteria do you have for your proposed fittings?

Working temperature ?

Working Pressure ?

working vacuum?

Chemical Resistance?

Identification markings and colours?

Inclusions for other fittings?

do you need Grips for handling?

Do you need a securing device to keep the fitting in place?

Do you need a strap to stop the attachment being mislaid or dropped?

what is the tolerance range for these products?

do the flasks have uniform dimensions or is there variance that needs to be taken into account?

Is there a need for a 3D printed fitting Rubber bungs have been used for an incredibly long time. they are inexpensive, simple, effective, and available in a number of formats

and no doubt there are many more criteria that may be important!

For a Simple Bung, create a suitably truncated cone to mimic a simple rubber bung and try printing it from a soft TPU Material.

I would do this in 123D design this is stone age software and I am a relative dinosaur

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

answer joan's questions first

Joan asks great questions and those would definitely be worth answering before you start modeling anything. Thanks Joan!

parameterization

This is something that could greatly benefit from parameterization. If I were doing this I'd likely opt for using openscad.

This allows you to set variables at the top that define the various dimensions so you can generate .stl for various sizes of flask.

Their documentation is pretty good and I was able to come up with something pretty quickly.

I can attach a quick example if you're interested.

Thank you for your suggestion. I try to read up on parameterization, which for me is a completely new concept.

questions and purposes

What criteria do you have for your proposed fittings?

Working temperature ?

Working Pressure ?

working vacuum?

Chemical Resistance?

Identification markings and colours?

Inclusions for other fittings?

do you need Grips for handling?

Do you need a securing device to keep the fitting in place?

Do you need a strap to stop the attachment being mislaid or dropped?

what is the tolerance range for these products?

do the flasks have uniform dimensions or is there variance that needs to be taken into account?

Is there a need for a 3D printed fitting Rubber bungs have been used for an incredibly long time. they are inexpensive, simple, effective, and available in a number of formatsand no doubt there are many more criteria that may be important!

For a Simple Bung, create a suitably truncated cone to mimic a simple rubber bung and try printing it from a soft TPU Material.

I would do this in 123D design this is stone age software and I am a relative dinosaur

Regards Joan

Thanks for the food for thought, JoanTabb!

Obviously the idea of the cap is just a simplification, but for the moment I would like to concentrate on solving the problem I proposed: how to start the correct modeling of a device that can be applied to flasks with a neck of different sizes and shapes, such as those shown in the image.

An idea that came to my mind was to make the object in two parts: an upper (cap) fixed, the same for everyone, and a lower one adaptable to the various shapes / sizes of the flask neck, with an easily removable screw or interlocking connection system.

But the point (for a neophyte like me) is: where do I start from?

...But the point (for a neophyte like me) is: where do I start from?

First, you need to have pretty much clear idea about design of the cap. It can be simple two cylinders connected (bigger on top, so cap don't fall into flask), or something more sophisticated (i.e. cutout in the throat part, where you can put some rubber ring for sealing), etc. etc.

Once you know how cap should look (and what criteria it should meet), you start with drawing in some CAD software -there's no other way. I recommend FreeCAD, which is quite intuitive, easy to start with and free. In my opinion, 3D printer is useless without knowing at least basics about 3D design.

[Mini+] [MK3S+BEAR]

more specifications

Certainly, but as I tried to point out in my answer -hoping to have succeeded - I am really at the initial stages of learning and I probably also need "basic" suggestions to understand how to approach the study of a simple project such as this.

The goals I set myself are the following:

a) make two interlocking components: an upper fixed part (the cap in the most common sense of the term) and a lower adaptable part for the various necks of the flasks (at this stage 2 or 3 types may suffice)

b) print them with my Prusa i3 MK3S by using PLA 0.75 with acceptable quality

Regarding point a) I wonder if I should start by taking the measurements of the neck of a flask (height, external diameter, internal diameter, lip measurement) or if I should start with 3D modeling with parameterization.

An obscure point for me is how to ensure the closure of the device without using o-rings or other sealing components (eg gaskets).

I hope I have placed my requests clearly.

Otherwise, just ask, and I thank everyone for your patience and participation in this discussion.

Thank you

Joan asks great questions and those would definitely be worth answering before you start modeling anything. Thanks Joan!

FreeCAD

...But the point (for a neophyte like me) is: where do I start from?

First, you need to have pretty much clear idea about design of the cap. It can be simple two cylinders connected (bigger on top, so cap don't fall into flask), or something more sophisticated (i.e. cutout in the throat part, where you can put some rubber ring for sealing), etc. etc.

Once you know how cap should look (and what criteria it should meet), you start with drawing in some CAD software -there's no other way. I recommend FreeCAD, which is quite intuitive, easy to start with and free. In my opinion, 3D printer is useless without knowing at least basics about 3D design.

I'm perfectly agree.

I'm following video tutorials to practice FreeCAD and simple object modeling.

Then I will ask myself the question of how to produce an STL and G-Code file with PrusaSlicer and Pronterface...

Do you have any suggestion for good video tutorials for learning FreeCAD ?

There is practical, and then there is fanciful

Your questions seem to be moving towards "how do I learn to think like an experienced design engineer" ... there aren't no shortcuts IMO. Go to college is the first step. But perhaps you can start a "joint brainstorm me something till I say it is what I was looking for ....". I like the bung idea. Your criterion for air tight (IMO) eliminates a million cap-like approaches. FDM prints ain't gonna be air tight unless there is some compression involved ... (BUNG BUNG BUNG!!!)

directions?

Hi,

maybe you are looking at this from the wrong perspective.

This is a Journey.

when you plan a journey, you generally need to know where you are going before you make your plans.

If you ae going international, overseas, you probably won't travel by car

If you are going somewhere you know, that is close by, you probably won't even need to look at a map...

If you don't actually know how to get to where you are going you will often look at a map first and then consider options

but it's useful on a journey, to know something about where you are going, and what you are going to do on the way and when you arrive...

sometimes it is worth looking to see if there is say a package tour, that saves you planning most of the details...

Have you looked in say Thingiverse... Is there something that you can use directly or modify?

https://www.thingiverse.com/thing:1460490 (Tapered Bung with hole)

https://www.thingiverse.com/thing:464609 (Paralell sided Bung No Hole)

https://www.thingiverse.com/thing:1136087 (it ma be possible to scale this model in Prusa Slicer!)

then when you get there it may be a good idea to be prepared for the temperature and conditions. for arguments sake

If it's hot, where you intend to use the models, then PLA will not be an option But TPU and PETG May be an option.

If you only need a dust cover a simple model may suit

If you need a good seal, a more complex option with, maybe an 'o' ring would be a good idea (But take into consideration that a 3D print may be Porous. )

If you want a simple model for yourself, you may be able to use a simple program

If you want to pass the final results on to another manufacturer, you may need a more professional 3d design program...

at the moment it seems that you have not done the preliminary consideration. but you want people to tell you what to do next...

You don't seem to know where you are going and what you need to do to fit in when you get there...

Maybe someone else has a better Crystal ball...

I wish you well with your project...

I am just off to town, access and parking are a pain in the backside, so I am going to get as close as I can, by car, use free on street parking, and then as it's after 09:30 I can use my free bus pass to get into the heart of town without worry, and being near town I have a better selection of busses than If I travelled from home, where there is only one bus per hour. However if I was planning on picking something bulky or heavy up at the shops, maybe I would return by taxi, or use my own car and put up with the access and parking constraints...

There is no one correct answer in most instances...

Hence why I encouraged you to consider your requirements before starting your journey.

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

I'm following video tutorials to practice FreeCAD and simple object modeling.

Then I will ask myself the question of how to produce an STL and G-Code file with PrusaSlicer and Pronterface...Do you have any suggestion for good video tutorials for learning FreeCAD ?

To learn FreeCAD basics, I would recommend this collection of videos -just take a look on videos published in last two months (with "F" sign on title image) and start with the oldest.

Once you're are able to create some simple object (a cube, for example), you can export that object as STL file. Main idea is, you get the "feeling" whats about 3D CAD design.. after that your ideas will become more realistic.

Getting examples from thingiverse (as Joan suggested) is good for gathering ideas.. other than that, knowing how to design yourself in CAD software, is the right way to go. And it happens quite often, that modifying existing STL file turns out more complicated than making it from scratch. Just don't give up.

[Mini+] [MK3S+BEAR]