cant get print to stick on build plate

Hi

I'm still very new in 3D printing.

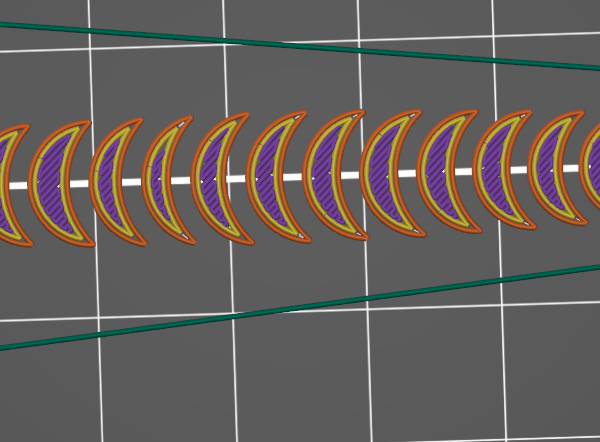

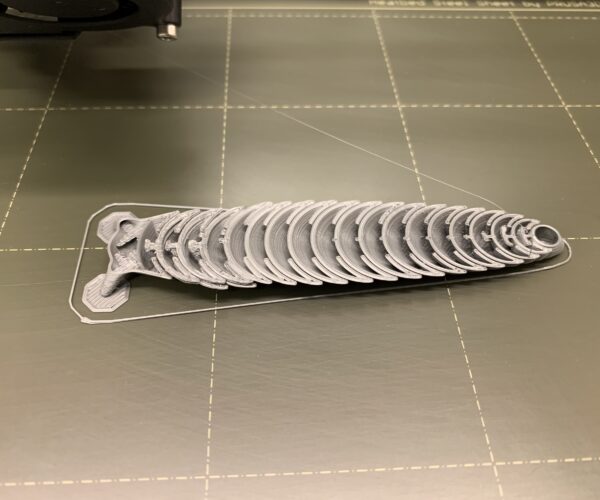

I have a Prusa MK3S+ and printing with PLA on a smooth steel sheet. I'm trying to print this slug:

https://www.prusaprinters.org/prints/71162-slug-fully-articulated-print-in-place

I have tried a couple of times to print using the 3mf file that contains changes to the print settings that the author states will print without brim other than on the antenna. This fails after a few layers with parts not sticking to build plate. I clean the plate with Isopropyl alcohol before each attempt.

I tried to redo z calibration and also decreased the distance between nozzle and build plate but still experience parts of the slug not sticking.

I looked through https://help.prusa3d.com/en/article/first-layer-issues_1804 and I believe that I have a correct z-offset when I compare with the images under the paragraf "The nozzle is too close/far from the sheet".

Any ideas of what I need to change to be able to print?

Thanks in advance

Best Answer by Diem:

That's an ambitious print for a beginner; I suggest you leave it for a while until everything is dialled in and the printer is spot-on.

Almost all adhesion issues come down to cleanliness and a correctly configured first layer Z offset.

Wash the build sheet with unscented dishwashing detergent (Dawn/Fairy) and plenty of HOT water. Dry it with a fresh paper towel and handle by the edges only. IPA is OK for maintaining cleanliness between prints but not enough once it is soiled.

Then please show us your first layer Z calibration print on the build sheet.

Cheerio,

That's an ambitious print for a beginner; I suggest you leave it for a while until everything is dialled in and the printer is spot-on.

Almost all adhesion issues come down to cleanliness and a correctly configured first layer Z offset.

Wash the build sheet with unscented dishwashing detergent (Dawn/Fairy) and plenty of HOT water. Dry it with a fresh paper towel and handle by the edges only. IPA is OK for maintaining cleanliness between prints but not enough once it is soiled.

Then please show us your first layer Z calibration print on the build sheet.

Cheerio,

RE: cant get print to stick on build plate

Adding on to what diem said, I tend to print the first layer for something like this very slowly and at a slightly higher temp to make sure the first layer adheres well. These sort of things often have very little contact with the build plate and thus the parts that are in contact must stick well enough. Besides the cleaning procedures above, try printing first layer at say 10mm/s. and maybe 218-220 for the temp. I normally don't use glue on the smooth plate for PLA, but for something like these I'd consider that or something like layerneer too to ensure you get good stick.

RE: cant get print to stick on build plate

Hi @diem and @ssill2

Thank you for the replies. I tried tuning the z height again and also washed the buildplate as described. The printer is currently printing and as reached approx 3 mm above build plate withput the print getting loose.

Thanks for the advice

RE: cant get print to stick on build plate

great news! Those articulated models can sometimes be very challenging to get to stick for the whole print. Crossing fingers for you

Hi @diem and @ssill2

Thank you for the replies. I tried tuning the z height again and also washed the buildplate as described. The printer is currently printing and as reached approx 3 mm above build plate withput the print getting loose.

Thanks for the advice

RE: cant get print to stick on build plate

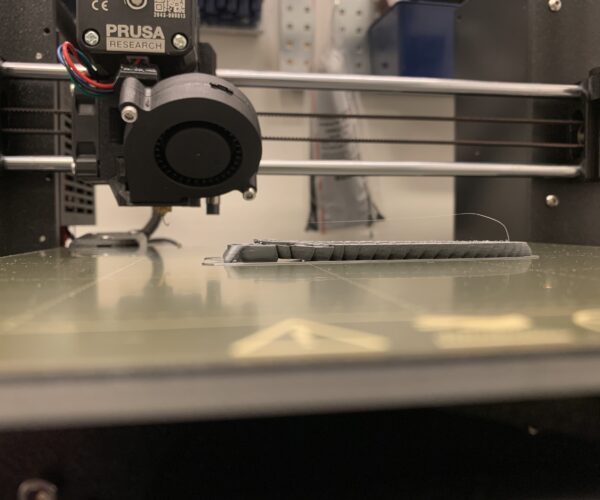

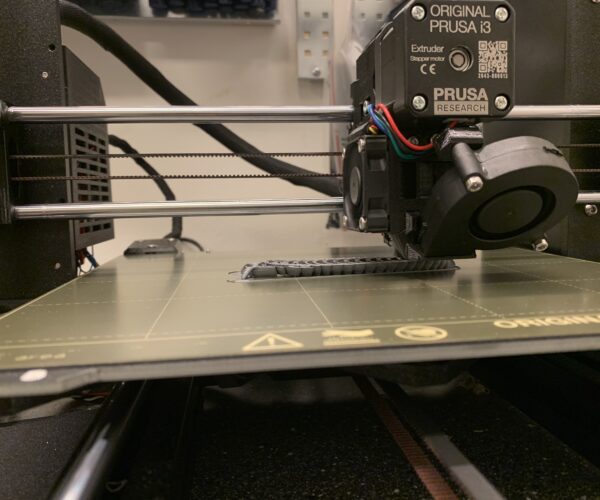

So unfortunately the print did not stick all the way through the print. I'm hoping that maybe someone can help me troubleshoot.

I'm especially puzzled that it didnt seem to be the smallest part that got unstuck. I have taken some images that maybe will lead to some insight.

First layer of slug:

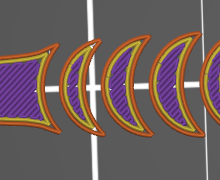

the tree parts just after the head of the slug that got unstuck. They are not at all the smallest and thereby the ones with the smallest contact area

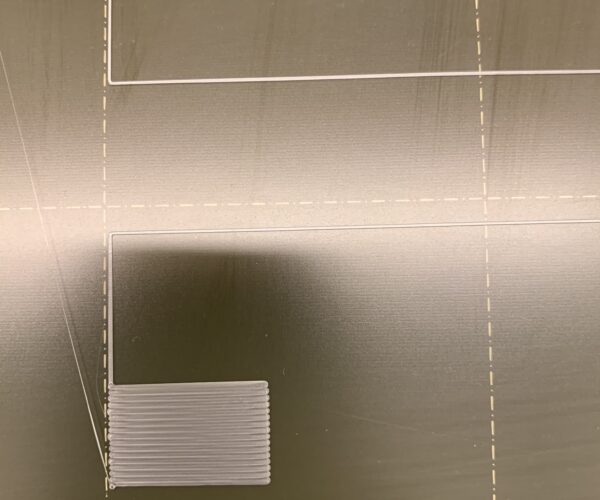

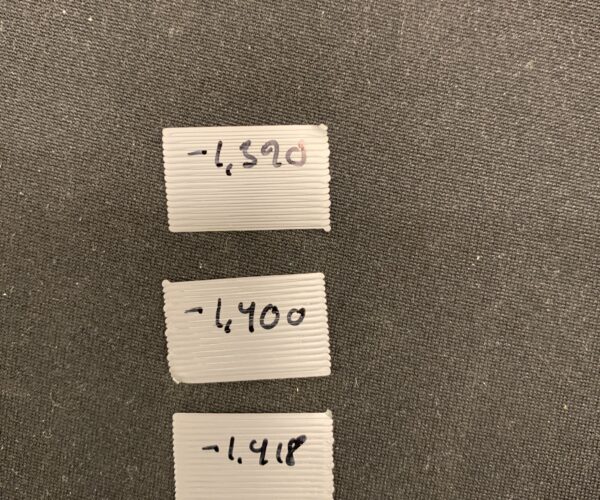

Final z calibration offset after som tweaking

Side view where you can see that it has liftet like a sort of warping. Also note that it seems to have gone wrong just a few layers before I stopped the print

Top view just to show how it looks when I stopped the print

tweaking z offset calibration (down side). I went with -1.390 since it seemed the nicest in terms of smooth surface and no surface artifacts like cluttered material that is visible on the other samples. I assume its because of the nozzle being too close and pushing material around

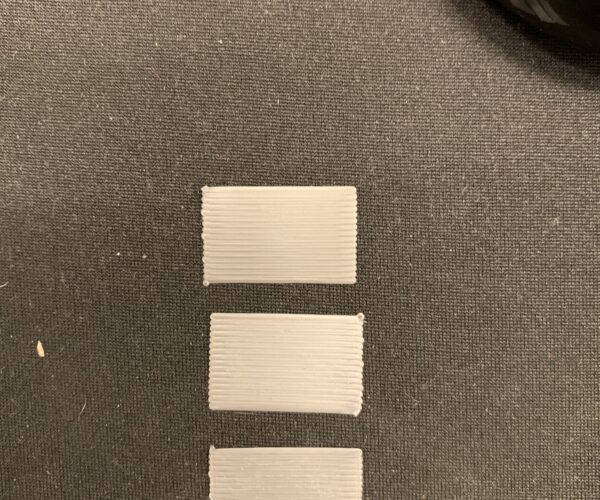

tweaking z offset calibration (up side).

The final z offset sample held against a light source to get an idea of even material thickness.

Any suggestions or comments are more than welcome. I'm considering increasing the bed leveling point count from 3x3 to a higher number - maybe the bed is just a little bit further from the nozzle around where the print got unstuck?

And happy new year to all:)

Your first layer Z looks OK. Yes, try 7x7 mesh bed levelling, it might help a bit...

but first wash the print-sheet again. There are visible smears in your pictures.

Cheerio,

RE: cant get print to stick on build plate

I can't tell, but are you using glue or some other adhesive? I have found increasing the print temp a few degrees can also help. This allows the filament to be lower viscosity and have less tendency to tug on the extrusions when the extruder is laying down filament. These articulated models are definitely a bit of a pain to dial in. You can also try reducing print speed a bit. Often I'll lay the first few layers down at 50% speed with the increased temp.

RE: cant get print to stick on build plate

Hi again.

I'm giving it another go. I have tried to thorougly wash the plate in dish washing soap (uncented, allergy friendly which I hope means with as few other chemicals as possible) and increased the bed leveling points to 7x7.

@diem: The reason for the visible smear is my initial misunderstanding of how to clean the plate. I thought I needed something with a mild scruffing effect so I used the scruffiest side of a kitchen sponge - that was probably a mistake. It left these smears but I hope it didnt ruin the plate - the following print actually adhered more than any of my other prints..

@ssill2: I didnt use any glue. If the current print fails i will try with some glue and increased temp. Do you increase the temp for the hope print or just the first layer?

Thanks for your advice

RE:

I find the Prusa first layer calibration tool difficult to use, so I use the

Life Adjust 'Z' My way process...

unfortunately the test files have disappeared from the bottom of the first post. so there are two main options,

you could look near the bottom of Page 42, or you could use the copy I add below... 🙂

S3D_calibration_surfaces_75x75@200um_v6.1

Regards Joan

the image above may help you see what is too low, what is too high and what is just right.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

You don't want glue for PLA, just get the sheet really clean and the first layer nicely squished.

Cheerio,

RE: cant get print to stick on build plate

I use the "scruffy" side of the kitchen sponge as well. it works great with the dawn and hot water. I do this for smooth plate and also satin and texture plates as well.

As far as temp, one of my two printers has a hardened steel nozzle so I increase the temp for everything by 6 degrees for that printer just by default. I would stay at 215 the whole print. I definitely think you're going to find that a little help from glue, layerneer, whatever is going to give you the extra stick you need for something that has so little build plate contact.

Try this:

Do do the plate cleaning:

Set your temp to 215 for the whole print.

Set your first layer speed to 10mm/sec. This allows the every extrusion on the first layer to be laid down with ample time to stick. Leave all the other settings the default. For anything that has very small extrusions on the first layer I always go slow to give them a chance to get a foothold before the nozzle start jumping around.

I have a few projects printing for my wife at the moment, but if you're still have problems in a day or two I can try to give your print a try and see if I can get you a .3mf that works.

Hi again.

I'm giving it another go. I have tried to thorougly wash the plate in dish washing soap (uncented, allergy friendly which I hope means with as few other chemicals as possible) and increased the bed leveling points to 7x7.

@diem: The reason for the visible smear is my initial misunderstanding of how to clean the plate. I thought I needed something with a mild scruffing effect so I used the scruffiest side of a kitchen sponge - that was probably a mistake. It left these smears but I hope it didnt ruin the plate - the following print actually adhered more than any of my other prints..

@ssill2: I didnt use any glue. If the current print fails i will try with some glue and increased temp. Do you increase the temp for the hope print or just the first layer?

Thanks for your advice

RE: cant get print to stick on build plate

Hi @joantabb

Thanks for pointing to this post. I havent tried the procedure but I see the point in doing it this way.

I think I'm duing someting similar using the build in z-calibration procedure - creating several prints where I vary the z offset, write the offset directly on the printed first layer and in the end compare the various z-offset first layers.

I find the Prusa first layer calibration tool difficult to use, so I use the

Life Adjust 'Z' My way process...unfortunately the test files have disappeared from the bottom of the first post. so there are two main options,

you could look near the bottom of Page 42, or you could use the copy I add below... 🙂S3D_calibration_surfaces_75x75@200um_v6.1

Regards Joan

the actual live Z value is unique to every printer,

the image above may help you see what is too low, what is too high and what is just right.

regards Joan

RE: cant get print to stick on build plate

Hi @diem and @ssill2

I ended up with a successful print. I did a combination of your suggestions. I gave the build plate a thorough cleaning with dish washer soap and a kitchen sponge and reduced the print speed for the first layer to 50%. The final print of the slug had working articulated joints after some handling of each joint according to the original post.

Thanks again to everybody for all your great suggestions.

Splendid.

RE: cant get print to stick on build plate

I am having a difficult time getting anything to stick to my build plate. I have washed the plate and dried it with a soft cloth, to make sure there are no fingerprints on it. I put some glue stick on the plate. I have tried printing the Prusa logo file that is on the SD card that came with the printer. The outline prints fine, but the inner box with the logo name on it lifts up. I am using the gray PLA filament that came with the printer. The temps are 60 degrees for the bed and 210 for the filament. I have tried adjusting the first layer print, but it seems to stick just fine until I get about 19 minutes into the print. I have tried several different files from the SD card, and they all have the same problem. This just started today. I have been able to print a cookie cutter and the "buddy," tree frog, and vase files just fine. They all stuck to the bed just fine.

I have another printer (not a prusa), so I have some experience with 3D printing, but this is my first Prusa. I have the MK3S+. It is just frustrating, because I have done nothing to alter the printer settings from the times when it was printing fine. I tried another new roll of PLA and it had the same issue. It looked like it was sticking, but about 15 minutes into the print, the item would not stick to the bed. This is with the glue stick applied to the bed.

I'm not sure what to do next - increase the bed temp? Try adjusting my first print layer? Help?

RE: cant get print to stick on build plate

Did you wash the plate with dishwashing detergent? IPA alone is not enough to clean it.

Mk3S+,SL1S

RE: cant get print to stick on build plate

Yes, I used Dawn and when I dried it, I did not touch it with my fingers. I then applied a new layer of glue on it. I just washed it again this morning and dried it and put a new layer of glue on it. I am printing a cookie cutter now using the Prusa PLA that it came with. I've never had this much of an issue with anything sticking before.

RE: cant get print to stick on build plate

Things that have relatively little contact with the build plate can be a challenge. For these things I got a a bit hotter and slower for the first layer to ensure good adhesion.

Yes, I used Dawn and when I dried it, I did not touch it with my fingers. I then applied a new layer of glue on it. I just washed it again this morning and dried it and put a new layer of glue on it. I am printing a cookie cutter now using the Prusa PLA that it came with. I've never had this much of an issue with anything sticking before.

RE: cant get print to stick on build plate

I think that is what I will do. I raise my bed temp to 65 and slow down my speed and see if that helps. My cookie cutter lifted right off of the plate. This does not happen with my other cutter. It is quite frustrating.