Cannot use complete built plate - Parts lifting at the edges

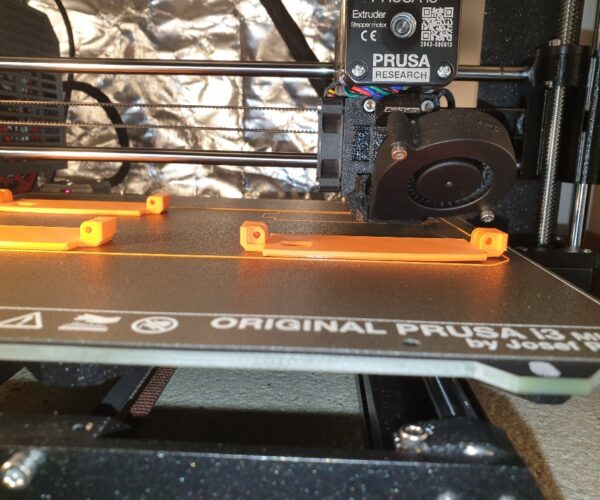

Hi there, I´m printing a lot of similar parts for the first time, so I tried to put as much parts as possible on the build plate and use sequencial printing, so one part is printed after another.

With 6 Parts on the Built Plate, 2-3 warped and lifted at the edges. Reducing that to only 4 parts, and concentate them more in the middle was a functional workaround.

Next Parts to print are slightly bigger parts, and from 4 of them on the built plate already 2 warped and the 4th is most likely ging to be.

I´m Printing eSUN PETG at Generic PETG Settings (240°C/230°C Nozzle and 90°C/85°C Bed), which turned out always perfect prints, as long as I don´t print close to the edges of the sheet. It´s the structured sheet, kept clean with ISO. I have an enclosure, this mitigates the issue, but does not solve it. Print Bed is levelled with Nylock Mod, pretty straight and the first Layer Calibration looks good to me.

So what is the trick here, to be able to fill up the bed without needing to worry about something lifting up ?

Thanks for your help,

Manuel

RE: Cannot use complete built plate - Parts lifting at the edges

I can't help other than to say I am having the exact same issue on my newly built MK3S+.

RE: Cannot use complete built plate - Parts lifting at the edges

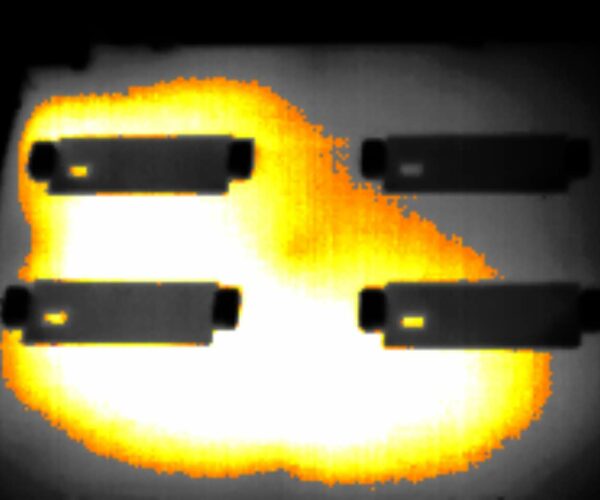

It's quite obvious that print sheet is much colder on back-right corner. You say you did Nylock mod.. maybe you should check if some of bolt heads don't protrude out of bed (in that case direct contact between bed and print sheet is lost).

[Mini+] [MK3S+BEAR]

RE: Cannot use complete built plate - Parts lifting at the edges

It's quite obvious that print sheet is much colder on back-right corner. You say you did Nylock mod.. maybe you should check if some of bolt heads don't protrude out of bed (in that case direct contact between bed and print sheet is lost).

THanks for the hint, will definately check that. Right now same print as before is running, but this time with 5°C higher bed temp. So far nothing lifts....

RE:

Increasing Temperature again mitigated the effect, but there was still lifting on the parts.

My Workaround now is: Printing only 2 Parts at a time, which will take forever. Tomorrow I´m going to contact service....

And the screws are below flush, so they do not interfere with the coated sheet.

RE: Cannot use complete built plate - Parts lifting at the edges

Hi,

apart from the obvious issue of the uneven heating built plate, give it a good scrub with unscented dish soap and very hot water. Isopropanol mainly helps spreading fatty residue around evenly, thus making adhesion more of a problem.

And I'm sure you did a nice first layer calibration with the Jeff Jordan square...

Cheers

Hansjoerg