C-Clamp Ball & Socket

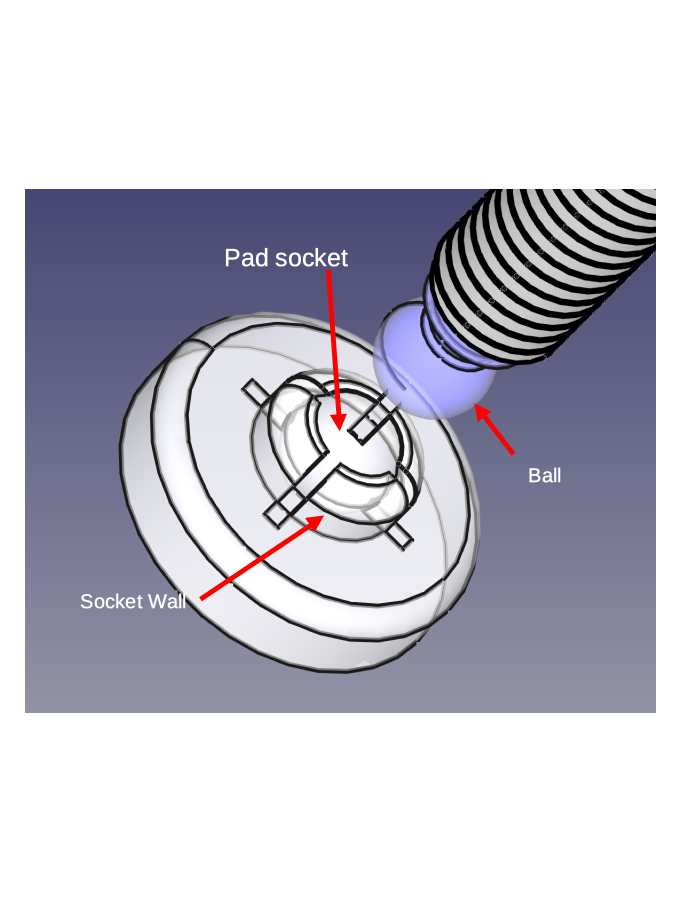

I'm making a c-clamp similar to the Prusa c-clamp ( https://www.printables.com/model/758-petg-prusament-clamp) where the screw has a ball on the end that will press into a socket of the pad thus allowing the pad to move somewhat on the end of the ball. I'll be printing the project on an i3MK3S+ with PETG.

I have a couple questions about clearances. My plan is to make the ball on the end of the screw 10 mm in diameter. The screw shaft itself will be 1/2". I am using a subtractive sphere primative (FreeCAD) to pocket the socket into which the ball will fit. My first question: how much if any clearance should I allow between the ball and socket? Should the socket be made maybe 10.25 mm diameter? Larger? Smaller.

Not having made anything like this before I'm also concerned about designing the socket walls so that I can actually press the ball into the socket without breaking them. How large does the opening need to be to allow the 10 mm ball to slip into the claws of the socket and how thick should the socket walls be?

If anybody has any recommendations on these things or knows of a page or video that discusses making a ball and socket arrangement such as this so that it works I'd appreciate the info.

Thanks.