RE: Bulge when print reaches "solid" layers

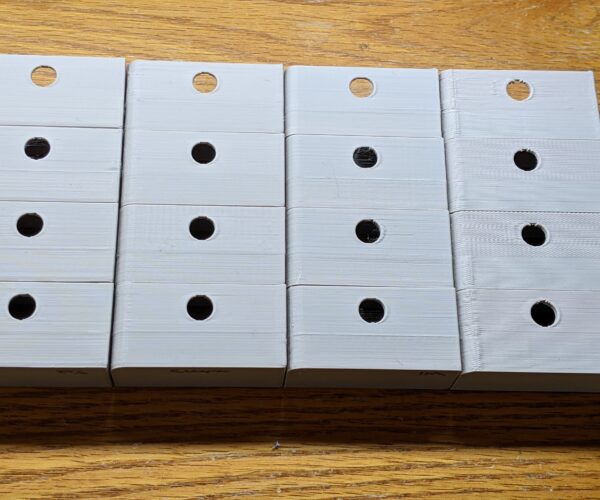

So this one was a new one for me: an "inverse bulge". Right in line with the screw holes, the bulge is inward, not to the outside as I usually see it at transition points from a solid surface to an empty space.

Inside view:

Outside view:

Actually, looking at the last picture I now realize that maybe it is the "standard" bulge issue after all, just slightly differently instantiated...

Looks like it bulges out at the transition from the box bottom to the empty space, as usual, but the bulge continues all the way up to the screw hole, where it retreats to where the wall should be, just to start again all the way up to the top.

I must admit after 20+ page of this I still have no firm grasp on what's going on here... It seems to me that the solution involves making the slicer algorithm "look forward" to upcoming changes in the model topology. But this example now makes me wonder how far ahead it has to look as I don't understand why the screw hole triggers a change. Looking carefully, the bulge is not retreating when it hits the screw hole but only about 1/4 of the hole's diameter up, and then it starts up again at about 3/4 up the screw hole, not at the top.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Bulge when print reaches "solid" layers

@fuchsr

Back when I was trying to discern the whys, I found that in many cases it isn't a bulge so much as an offset. The wall thickness doesn't change, but moves one direction or another. Your part shows that effect rather clearly. Almost as if the slicer really is screwing up. But I dove deep into the gcode and found the coordinates for the print moves were identical, yet, the filament was placed in the wrong spot. It really points to a firmware defect. And, I found the problem was directional - reversing print move direction was just as likely to cause an offset as anything else. In your print, I suspect the print direction at the offset is reversed.

Who knows, maybe a lot of this is simply our printers have backlash.

RE: Bulge when print reaches "solid" layers

I'm convinced this is simply an issue with the current approach to slicing. At best, all are trying to approximate results, and doing so with fixed perimeter extrusion widths throughout the print. Looking at Angus' "flawless" prints on his Maker's Muse YouTube channel, you see these flaws everywhere. Back a few years ago, we were happy to get any sort of consistency, so considered a sub-mm deviation acceptable. Much like the "602" issue, once seen, you can't unsee the problem, and we're setting higher expectations. I've seen the same issues with PrusaSlicer, Cura, ideaMaker, and Simplify 3D. I've seen the same issues on Prusa i3 Mks and Artillery Sidewinder X1s.

Here's a comparison of 1.35, 1.5, 1.8, & 2mm wall test prints done with (L-R) PrusaSlicer, Cura, ideaMaker, and Simplify 3D:

(S3D can definitely generate better prints than this. I just loathe working with it, and this is enough to show deviations between layers, which is the point.)

I think a new approach to slicing is ultimately "the best" answer. I have not had any luck with Cura's new Arachne engine yet, but am following it closely. In the meantime, we get to twiddle away with settings based on our choice of filament, parameters, and STL characteristics. We're still in the early enthusiast/tuner stage of this technology. I'm not expecting any miracle setting to fix this problem for all situations.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Bulge when print reaches "solid" layers

This sounds like a great Master thesis to me, in particular if you throw a bit of Machine Learning into the mix to be buzzword compliant. I'm actually being serious. As Bob said, this still feels like the early days for slicers, with the potential to seriously improve algorithm effectiveness, probably in conjunction with firmware improvements.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Bulge when print reaches "solid" layers

I'd like to find a slicer that has the ability to control extrusion directionality. Similar to Pslicer's monotonic for layer fill; but for everything. If printing a perimeter, it must always fill clockwise.

I suppose one could code examples to prove the assertion the effect is akin to backlash. Print a part 50 layers high, reverse perimeter direction another 20 layers, then reverse back to original and print another 50 layers.

Has anyone ever seen a bulge in a vase mode print?

RE: Bulge when print reaches "solid" layers

I'm not arguing against the idea of directionality being involved but vase mode alone doesn't make that case because by definition you can't have those transition points defined by an internal top layer with walls around it continuing, which seems to be the textbook example of causing the bulge.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Bulge when print reaches "solid" layers

@fuchsr

was just thinking the same. someone said he could predict when the bulge is going to happen. if so, then it's a straight line to a ML model from here

and the community will provide enough examples to train it

RE: Bulge when print reaches "solid" layers

@fuchsr

But doesn't your latest example show that layer infill is not required? That a simple opening in a wall is all it takes?

RE: Bulge when print reaches "solid" layers

I think over the last 3 years, we've gone from "I could spend a few minutes sanding this down and make it mirror smooth" to "I don't want to spend a few minutes sanding this to make it mirror smooth". I have looked for a super-simple slicer that doesn't do any fancy calculations, just "print it with my settings". All of the advanced slicers do their own thing behind the scenes and I sometimes think I'm chasing my tail based on bad assumptions.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Bulge when print reaches "solid" layers

I'd like to find a slicer that has the ability to control extrusion directionality. Similar to Pslicer's monotonic for layer fill; but for everything. If printing a perimeter, it must always fill clockwise.

I suppose one could code examples to prove the assertion the effect is akin to backlash. Print a part 50 layers high, reverse perimeter direction another 20 layers, then reverse back to original and print another 50 layers.

Has anyone ever seen a bulge in a vase mode print?

Just to be clear I'm not here to discuss bulge I'm here because of this quote, I am about to go to github and make a feature request for something like this, however it's not as much about direction as it is we need a way to show more specifically where we want the print head to go next, many times it is important, and more then helpful to direct the print head where we need it next, in several 3d packages there are whats known as "shape hints" and they allow us to steer a shape or morph a shape based on placement and weight, I see no reason why this cant be done in slicer relative to the layer height and position of the print head, I had been waiting to post on GitHub until I could make a good example to offer the Devs and I have been using work arounds in Prusa slicer to do this for the last 4 yrs now. But I think slicer is ready for this feature now and I know I am.

It's not that we can't just write g-code and do this per project, however the point of slicer is a graphical user interface to make this visually easier for placement of parts, model features and supports alike. as is stands now I have to create null objects and place them to steer the print head and its hit and miss to get the result I need.

I'm all for it.

Swiss_Cheese

P.S @fuchsr

you have a extrusion width issue, adjust it.

The Filament Whisperer

RE: Bulge when print reaches "solid" layers

@tim-2

Not sure what my model shows but the bulge certainly requires SOME change in topology that appears to involve laying down top layers (in this the circumference of the screw hole), maybe among other factors. I have used vase mode less than the fingers on one hand but my understanding is that it requires models that don't meet that criterion.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Bulge when print reaches "solid" layers

@bobstro

lol - yeah - and that's why I am building a test part with simple perimeters that I can edit in Notepad and change print direction in a middle of an otherwise plain and simple wall. Perhaps even add obtuse moves so that the extruder comes in from different directions for a set of layers, then starts a new set of layers from the other side. I just want to satisfy my gut that simply backlash isn't the start of the problem, and that acceleration and print speed also isn't a direct contributor.

Seriously - how complex is printing a single line. What I found before, that the X and Y positions and travel are identical and the extrusion amount is identical, and the only variable was the start/end points and the direction the extruder traveled. Yet, there was a offset in wall position in the print. That fact has haunted me... lol.

RE: Bulge when print reaches "solid" layers

@fuchsr

What top layers does that hole have right in the middle? Yet, the bulge is continuous top to bottom of the hole. I'm not convinced it takes layer infill at this point.

RE: Bulge when print reaches "solid" layers

P.S @fuchsr

you have a extrusion width issue, adjust it.

Huh, how do you know?! My wife said the same thing. Wants me to go on a diet to get rid of the bulge in the middle... 😇

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Bulge when print reaches "solid" layers

[...] lol - yeah - and that's why I am building a test part with simple perimeters that I can edit in Notepad and change print direction in a middle of an otherwise plain and simple wall. Perhaps even add obtuse moves so that the extruder comes in from different directions for a set of layers, then starts a new set of layers from the other side. I just want to satisfy my gut that simply backlash isn't the start of the problem, and that acceleration and print speed also isn't a direct contributor.

I've looked back through the Slic3r archives and peeked at 0.05. Not sure I'm ready to dive back into PERL though. Skeinforge was apparently another very simple early slicer. Those might give you a good starting point.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Bulge when print reaches "solid" layers

I think over the last 3 years, we've gone from "I could spend a few minutes sanding this down and make it mirror smooth" to "I don't want to spend a few minutes sanding this to make it mirror smooth"

Although I am following this discussion, I must admit I'm still at the "sanding" stage in my own evolution, in which I just want functional parts that serve a purpose other than having a perfect finish. The problem that bedevils me the most is poor layer adhesion for some PLA colors. If I see a strange bulge that wasn't in my design, I'll just sand it off -- and I find myself doing that anyway to get close-tolerance moving parts to fit.

I observed that PrusaSlicer has a setting to print the infill first. Maybe that's mentioned buried deep down in this lengthy discussion, but I don't recall seeing it. I wondered if that would make a difference.

RE: Bulge when print reaches "solid" layers

P.S @fuchsr

you have a extrusion width issue, adjust it.

Huh, how do you know?! My wife said the same thing. Wants me to go on a diet to get rid of the bulge in the middle... 😇

Married for 25 years long ago, it was an educated guess 😉

The Filament Whisperer

RE: Bulge when print reaches "solid" layers

@bobstro

I went with notepad. Slow, but steady. The result of reversing perimeters was visible, mostly in sheen, and some odd ridges on the corners going one way but not the other, but nothing I'd call a bulge. So reversing has artifacts I can't explain easily, but easily within what we'd all call acceptable. I'll go back and add infill along with the reversing when I get a few spare moments and am bored enough.

RE: Bulge when print reaches "solid" layers

Hi all, I use SuperSlicer (which I believe is a fork of Prusa Slicer?) And wanted to chime in. I'm having an issue which I think is related to the bulge issue being discussed here. Very consistent layer "bulge" artifacts that are perfectly repeatable with the same gcode. They are not random artifacts caused by the printer. In my pic the first two are printed by SuperSlicer and the third is after I switched back to Simplify3D. I have not been able to find any solution so I quit using SuperSlicer.

The promised land... some day PrusaSlicer... some day.

That cube looks great!

On that note, anyone seen any future update logs or notes regarding the bulge being addressed in Prusa Slicer?

Hi all, I use SuperSlicer (which I believe is a fork of Prusa Slicer?) And wanted to chime in. I'm having an issue which I think is related to the bulge issue being discussed here. Very consistent layer "bulge" artifacts that are perfectly repeatable with the same gcode. They are not random artifacts caused by the printer. In my pic the first two are printed by SuperSlicer and the third is after I switched back to Simplify3D. I have not been able to find any solution so I quit using SuperSlicer.

MK3s / My IKEA Lack enclosure