RE: Bulge when print reaches "solid" layers

I have been struggling with the same issue for some time now but thanks to this discussion I think I've managed to eliminate most of it (at least for my test models).

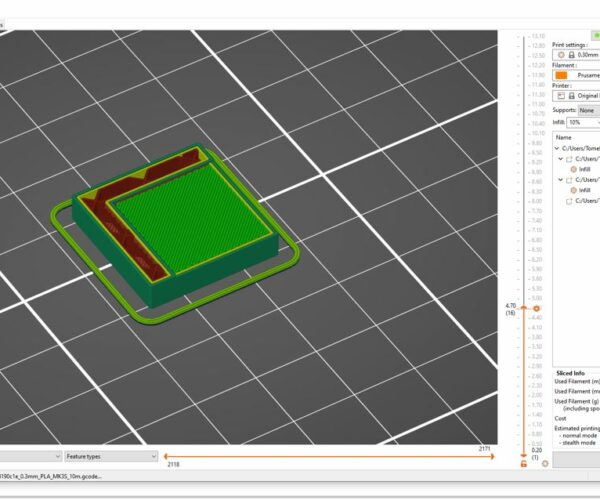

As mentioned earlier in the topic, the issue mostly(only?) occur when a wall meets a floor or rather when the slicer decides to print a wall on top layers (picture 2). That was also confirmed by my prints.

The extended bridge infill into the wall causes the bulge as confirmed by prusa in the their benchy-hull-line article.

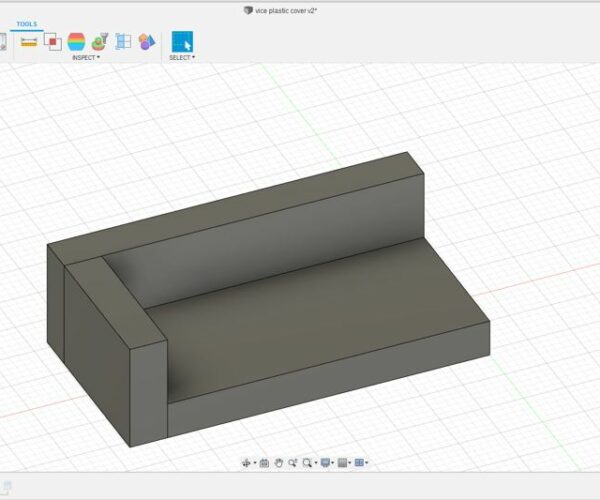

This is how Prusa slices the model by default

And this is how we want it to be:

I came up with two different ways how to slice the model without extending the bridge infill into the walls.

1. Split the model in cad software into bodies of walls and floor(pic1) and then split it to parts in the slicer. For each wall part set infill value different from the infill of the base part. In my tests, my default infill was 10% and I set 15% for the walls

OR

2. Create modifiers covering external portion of the walls (leave a small gap between the inner wall and the base part to allow some bridge overlap); set top layers to zero for the modifiers. This will have same slicing effect as in the point 1 but with the uniform infill value; of course the modifier should be shorter than the wall itself otherwise not top layers will be printed for them, neither.

Both approaches resulted in a clean print although option2 can be quite fiddly to position correctly.

Also for all my prints I set the value of "Slow down if layer print is below" to 5 to eliminate any speed variations.

I believe this could be a quick fix in Prusa slicer as I don't see a reason why the top layers are generated for the entire base and not for the visible part only. Cura does it by default.

Maybe we could have an option in the slicer like "Infill wall overlap" with some % value of the wall thickness. This would allow even faster testing.

Not sure this is going to work for other models but let me know if you had any luck with it.

RE: Bulge when print reaches "solid" layers

@kotekbury

I know your comment is a bit older, however I recently began really wanting more cosmetically better parts because they are cosmetic. (duh). And This "bulge" was very apparent with the transition to "thicker/denser are" to a thin wall. I know I have NO layer shifting issues (just trust me). But when finallying learning its a bulge, I tried your "fix" with the modifiers. It makes sense to have the perimeters be more "continuous" rather than starting on a whole new surface. And I did the layer slowdown and etc, and I gotta say, very happy I found this topic. The bulge is greatly reduced to the point where you need to search for it, but that's also due to me having the area much closer to the bed than the first print. But not only is the bulge reduced, the layers are also more aligned. Now I just need to figure out the best way for even thinner walls so I'm less limited on how the modifiers and such can be effective.

All in all, I am impressed on how simple this fix was and I'm happy to have learned this to make overall designs better for this and understanding how to fix these issues. So, thanks!

RE: Bulge when print reaches "solid" layers

I am facing the same type of bulge issue.

bobstro's post regarding constant volumetric speed printing has solved the majority of the bulge. There will still be a tiny bulge because along the z axis you have a layer with say 20% infill and the next immediate layer has 100% infill and then the layer above that is back to 20% infill. If you set the infill to 100% and print at constant volumetric speed then that should eliminate the bulge totally

The best solution is to fix it in the slicer such that the entirety of the infill is consistent and then use constant volumetric speed printing.

I also noticed that between two prints that take the same time to print, the one using constant volumetric speeds will be of higher print quality than the one sliced using my tuned prusa slicer settings. However, there is a bit more ringing visible.

RE: Bulge when print reaches "solid" layers

I have been struggling with the same issue for some time now but thanks to this discussion I think I've managed to eliminate most of it (at least for my test models).

As mentioned earlier in the topic, the issue mostly(only?) occur when a wall meets a floor or rather when the slicer decides to print a wall on top layers (picture 2). That was also confirmed by my prints.

The extended bridge infill into the wall causes the bulge as confirmed by prusa in the their benchy-hull-line article.

This is how Prusa slices the model by default

And this is how we want it to be:

I came up with two different ways how to slice the model without extending the bridge infill into the walls.

1. Split the model in cad software into bodies of walls and floor(pic1) and then split it to parts in the slicer. For each wall part set infill value different from the infill of the base part. In my tests, my default infill was 10% and I set 15% for the walls

OR

2. Create modifiers covering external portion of the walls (leave a small gap between the inner wall and the base part to allow some bridge overlap); set top layers to zero for the modifiers. This will have same slicing effect as in the point 1 but with the uniform infill value; of course the modifier should be shorter than the wall itself otherwise not top layers will be printed for them, neither.

Both approaches resulted in a clean print although option2 can be quite fiddly to position correctly.

Also for all my prints I set the value of "Slow down if layer print is below" to 5 to eliminate any speed variations.

I believe this could be a quick fix in Prusa slicer as I don't see a reason why the top layers are generated for the entire base and not for the visible part only. Cura does it by default.

Maybe we could have an option in the slicer like "Infill wall overlap" with some % value of the wall thickness. This would allow even faster testing.

Not sure this is going to work for other models but let me know if you had any luck with it.

If you slice that model using Simplify 3d it will not have the horizontal walls in the infill.

RE: Bulge when print reaches "solid" layers

Another thread a guy ( @swiss_cheese ) came up with a real solution worth trying. It has to do with inner perimeters and properly adjusting perimeter widths. He showed an example of a complex part with the bulges eliminated. It's worth reading about what he did.

Now if I can find it ...

RE: Bulge when print reaches "solid" layers

@tim-2

so, youre saying the elephants foot can be a cause??? Very interesting. I mean, the only way I see it being a problem, is if the slicer for some reason thinks a new layer after a top layer is "a first layer"...

I wonder if the developers have any thought.

RE: Bulge when print reaches "solid" layers

@synnota

It certainly could be. It is always at the level below the transitions from semi-solid to hollow layers for me.

--------------------

Chuck H

3D Printer Review Blog

RE: Bulge when print reaches "solid" layers

@cwbullet

Same here. Is there anyway to get a developer here??

RE: Bulge when print reaches "solid" layers

[...] so, youre saying the elephants foot can be a cause??? Very interesting. I mean, the only way I see it being a problem, is if the slicer for some reason thinks a new layer after a top layer is "a first layer"...

Based on my testing, any sort of transition can cause varying levels of defects. There are lot of variables, so results will depend on the specifics of the print, the specific transitions, and even the filament being used. I've seen the same occur with PrusaSlicer, ideaMaker, and Cura, so this isn't specific to any one slicer. I doubt Simplify 3D is immune but simply haven't bothered testing with it, or KISSlicer for that matter. My take is that this has been a persistent problem for years, but that we're only now setting print quality expectations high enough that people are complaining about sub-mm deviations. A few years ago, we probably would have been happy with these same results.

So far as actual fixes go, I'm watching Cura's Arachne engine development as it seems designed to address exactly this sort of issue. Up until now, slicers seem -- based on my outside understanding -- to have focused on layer-by-layer pathing with no look ahead or behind as to what the next or previous layers featured. I suspect we'll see slicers start to include more pre-slicing analysis and planning. For now, we're still hoping to get reasonable bridges and smooth top surfaces.

This feels like using a dot matrix printer in the early 1980s, hoping to see lower case descenders and variable character widths. Wee're still in the early days of this technology.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Bulge when print reaches "solid" layers

@synnota

No - I am not saying that - unless you are applying the term 'elephants foot' in a way I don't understand. Elephant's foot happens when a layer is squished due to weight of higher layers (or sustained higher temps above the glass point).

The gist of the finding in that other thread - in my limited understanding of it - is wall thickness: when walls are not aligned with perimeter thickness, the slicer will do its best to add the perimeters selected, but has an issue thinning them down to fit the available space. There are even words in Slicer to that effect, but it appears to be an arcane art to know the correct way to proceed. Swiss_Cheese laid it out fairly clearly, I thought. Though, I haven't had time to put his solution to practice where I can explain it myself.

RE: Bulge when print reaches "solid" layers

@synnota

Not really. One did comment along the "buldge" [sic] thread (or another thread discussing bulges). Basically he was saying it's wall thickness, and later we saw a few extra lines in slicer tool tips regarding the wall vs perimeter computation [or it was after that discussion I noticed the tip].

Head over to Github; there is a rather lengthy bug request on this subject, too. Come to think of it, maybe that was where I read the dev notes.

RE: Bulge when print reaches "solid" layers

@bobstro

I like the dot matrix analogy. One of my school projects was to write a font editor and text converter/driver to allow users to create custom bitmapped fonts using the Epson printer's graphics buffers: something better than the built in fonts that were rather dull.

RE: Bulge when print reaches "solid" layers

No sure of the cause, but I nearly 100% at predicting where it will occur in my prints.

--------------------

Chuck H

3D Printer Review Blog

RE: Bulge when print reaches "solid" layers

[...] The gist of the finding in that other thread - in my limited understanding of it - is wall thickness: when walls are not aligned with perimeter thickness, the slicer will do its best to add the perimeters selected, but has an issue thinning them down to fit the available space. There are even words in Slicer to that effect, but it appears to be an arcane art to know the correct way to proceed. Swiss_Cheese laid it out fairly clearly, I thought. Though, I haven't had time to put his solution to practice where I can explain it myself.

The situation is complicated somewhat by the fact that PrusaSlicer will vary the overlap between adjacent perimeters. While a single extrusion of 0.45mm will produce a wall that will measure close to 0.45mm, two extrusions of 0.45mm will not produce a 0.9mm wall. If I've got it right, 2 perimeters will produce a wall of 0.857mm thickness and 0.41mm extrusion centers with a 0.2mm layer height. Layer height is a factor, so this plays merry hell if you use variable layer heights. The width doesn't vary but the distance between adjacent extrusions does. From my limited testing, all current slicers do similar perimeter math. Perimeters stay the same width (unless you enable thin walls), but gap fill and/or extrusion spacing is varied. The big excitement with Cura's Arachne -- at least as I'm understanding it -- is that it will adjust extrusion widths to reduce the need for stuffing gap fill in between fixed-width extrusions.

My take on it is that it's a pervasive problem with all current-generation slicers, but one that's being worked on. A lot of people declare victory when they print with a slicer and don't see the problem, not realizing that they may have just found a happy default setting that works with one particular print. We want a solution that will work without fiddling with any print. In the meantime, we can have fun working on one-off fixes using a variety of techniques that may fall apart on the next print.

Slicer math can also throw filament extrusion multiplier calculations off. I'm updating my notes based on recent testing.

Sticking the word "buldge" in here so it'll show up in search results easily.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Bulge when print reaches "solid" layers

The perimeter issue is not related to the bulge issue.

The bulge issue is due to the slicer putting solid horizontal walls in the infill. Simplify 3d does not do this, so if you have simplify 3d you can avoid the bulge issue. In Prusa Slicer the only way to avoid the bulge issue is to set your infill to 100% so the infill is all horizontal walls so if the slicer puts horizontal walls in the infill that makes no difference as all the other infill layers are horizontal walls and the infill is 100% consistent.

RE: Bulge when print reaches "solid" layers

So glad that's been resolved then. Just print large models with 100% infill and no internal surface transitions. Thanks.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Bulge when print reaches "solid" layers

@toalan

I will try Simplify3D - thanks.

--------------------

Chuck H

3D Printer Review Blog

RE: Bulge when print reaches "solid" layers

@toalan

from my experience varying the infill between vertical and horizontal parts should give you the same results. no need for 100% infill.

just yet another hack...

RE: Bulge when print reaches "solid" layers

@toalan

from my experience varying the infill between vertical and horizontal parts should give you the same results. no need for 100% infill.

just yet another hack...

Can you post the settings you are using in PS? TIA

RE: Bulge when print reaches "solid" layers

@toalan

standard settings everywhere.