Bridge Infill on supports

Possibly a dumb question, but are you supposed to remove the Bridge Infill layer that PrusaSlicer inserts between the support and the object? I'm having a very hard time removing that layer with PETG, even with various recommended settings for Contact Z Distance, Interface pattern spacing, etc. and based on what I read on this forum and tried myself, there is no way to make PrusaSlicer not insert that layer.

RE: Bridge Infill on supports

I think the answer is no - don't remove that contact patch. It is how you get the thin support matrix that follows to have enough bed adhesion to not cause a failed print.

You have not said if you are having a hard time doing ... what exactly? Removing it from the GCODE file? Preventing it from being added to the GCODE file? Removing the interface layer from the bed after printing? Removing the matching interface layer from the top of the support layer? Removing the final interface layer (.2mm separation recommended for removable) from the printed part?

RE: Bridge Infill on supports

To be more specific, it's the Bridge Infill layer between the support and the part, so not the one on the bed. I'm having trouble separating the part from the supports. I set the separation to 0.2mm, and even 0.3mm and it's still extremely messy and difficult to remove.

Here's a picture. You can see most of the support material has been removed, but this layer is still stuck to the part (both the edges and to the bottom of the part).

RE: Bridge Infill on supports

Thats the bottom layer of your actual part, not an interface layer. The problem is that at the moment the filament strands don't fuse together side by side (as they dont get squished out sideways). In the preview you will see them as the light blue thick lines. While you can turn off detect bridging perimeters at the moment it still does the infill layer thickness at the nozzle diameter so you get those unconnected strands.

We are all hoping the next PS release 2.4 will fix these issues as its supposed to be targeting support related problems. Guess we will just have to wait and see.

RE: Bridge Infill on supports

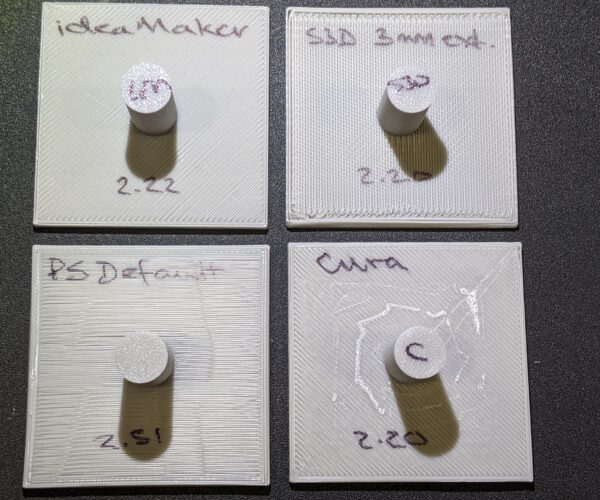

PrusaSlicer does put a bridge layer immediately below the actual part. This has been the basis of a lot of lengthy discussions here and on GitHub. This results in adding thickness to supported surfaces. Here's a comparison showing the results of a supported 2mm thick horizontal surface generated with (L-R, Top-Bottom) ideaMaker, Simplify 3D, PrusaSlicer and Cura.

You can see that, while bridging does results in a bit of additional thickness -- there's always a bit of sag -- prusaslicer's result is considerably thicker and uglier due to the bridge layer. I've forgotten the details, but it's also complicated by the fact that Z distance has to be a multiple of layer height IIRC. You can clearly the bridge layer it in preview mode. You can try to cut it away -- the supported surface above it does look very clean -- but the process is tedious and tends to wind up a mess. I am encouraged to read that Team Prusa is looking at bridging in a future release.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…