Bridge Infill looks stringy

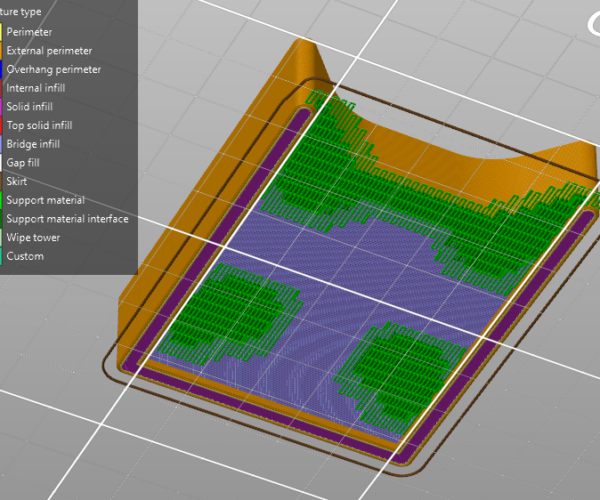

I just printed a plate that has perimeter feet that are 1.75 mm tall. I printed this with the feet side down in PLA. I sliced with PrusaSlicer 2.2.0 with the defaults for .15mm QUALITY and supports everywhere enabled. I toggled yes for the recommended bridging detection.

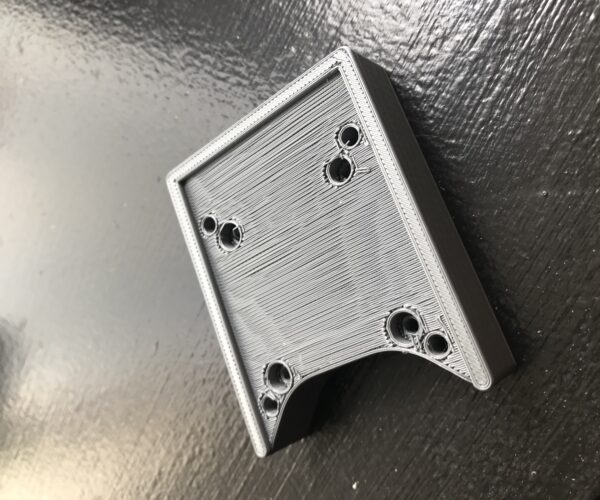

The feature that looks stringy sliced as Bridge infill here. Any suggestions to cleaning up that feature? I printed one from the other side and these features came out very clean but the functional surfaces that are on the other side of the part were not as clean. Any other general suggestions are welcome! (I'm new.)

Thanks!

Best Answer by tj:

Extrusions over air without anything below it will look stringy, this is because there is nothing below it for the filament to get squished against.

More support may make it less stringy but then you may have another problem of getting rid of the supports too.

Best is if you don't need any support.

Looking at your part it also looks like you have holes where you get bridging, this can be extra problematic and there are some tricks you can use when designing the part to make it not need any support for the holes to come out good.

Two ways of improving holes, one is to just design the part (or use modifier mesh in prusa slicer) and make a one layer thin sheet over the hole that you then later can cut out.

The other way is to design the holes such that the first two layers towards the bottom is square to make bridging work better and no need for support.

It is a bit hard to describe so have a look here:

https://shop3d.ca/blogs/blog/3d-printing-tip-1-designing-better-3d-printed-holes

RE: Bridge Infill looks stringy

Extrusions over air without anything below it will look stringy, this is because there is nothing below it for the filament to get squished against.

More support may make it less stringy but then you may have another problem of getting rid of the supports too.

Best is if you don't need any support.

Looking at your part it also looks like you have holes where you get bridging, this can be extra problematic and there are some tricks you can use when designing the part to make it not need any support for the holes to come out good.

Two ways of improving holes, one is to just design the part (or use modifier mesh in prusa slicer) and make a one layer thin sheet over the hole that you then later can cut out.

The other way is to design the holes such that the first two layers towards the bottom is square to make bridging work better and no need for support.

It is a bit hard to describe so have a look here:

https://shop3d.ca/blogs/blog/3d-printing-tip-1-designing-better-3d-printed-holes